4.5.3

Inhibitors, anti-freeze, biocides

You can use the following anti-freeze, inhibitors and biocides in the stainless steel cooling

circuit:

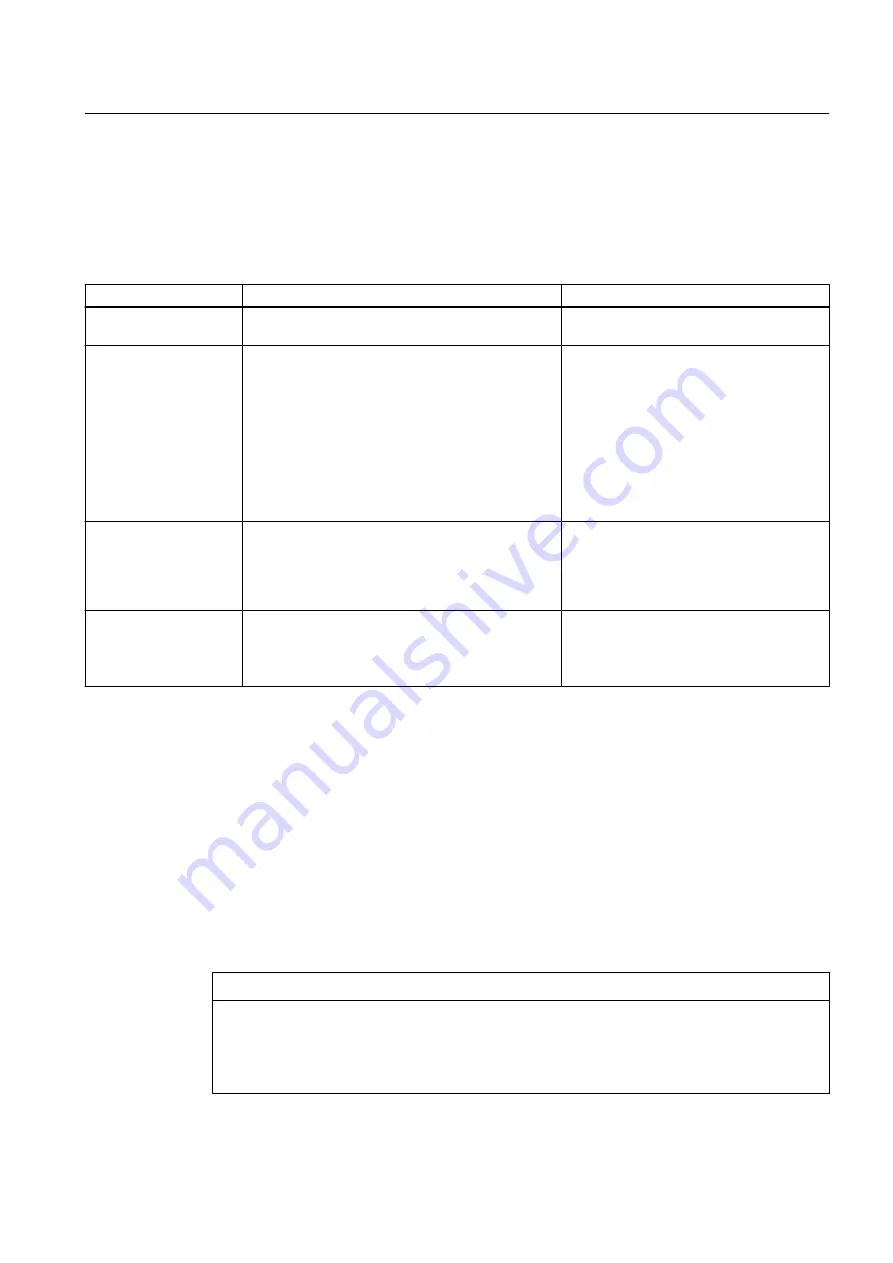

Table 4-3

Overview and application of coolant additives

Anti-freeze used

Please note the following in particular

Inhibitor without anti-

freeze effect

Not necessary

Inhibitor, 0.2 ... 0.25 % by volume!

Anti-freeze protection

● Antifrogen N: 20 % < X ≤ 45 %

A 45 % concentration provides frost protection

down to -15 °C.

● Antifrogen L: 25 % < X ≤ 48 %

A 48 % concentration provides frost protection

down to -15 °C.

● Varidos FSK: 20 % < X ≤ 45 %

A 45 % concentration provides frost protection

down to -15 °C.

● With Antifrogen L, for the same

antifreeze protection, a higher

concentration is required then for

Antifrogen N

Biocide*

Yes

● Antifrogen N, minimum quantity 20 %

● Antifrogen L, minimum quantity 30 %

● Varidos FSK, minimum quantity 30 %

Cooling circuit with open pressurizer

Anti biocide*

An Antifrogen N antifreeze concentration of >20 %

provides an adequate biocidal effect.

With Antifrogen L and Varidos FSK, 30 % is required

in order to achieve the same effect.

* Effectiveness regarding the growth of microorganisms

Inhibitor without anti-freeze effect

If you use inhibitors without any antifreeze effect, then it is not permissible that there is any

magnesium carbonate in the cooling/water used.

Only use the NALCO TRAC100 inhibitor from the Nalco company in the ratio 0.2 % up to

0.25 %. Control Kits can be ordered from Nalco to check the inhibitor concentration.

Anti-freeze

All antifreeze agents contain corrosion protection inhibitors, which permanently protect the

cooling system against corrosion. You can use the additives listed above as anti-freeze agent:

NOTICE

Corrosive mixture

Top up with antifreeze to comply with the minimum concentration, otherwise a mixture is

obtained that has a corrosive effect. The cooling system can be damaged.

● Never mix inhibitors and anti-freeze.

Preparations for use

4.5 Coolant specification

SIMOTICS FD 1LH1

Operating Instructions 01/2019

35

Summary of Contents for SIMOTICS FD 1LH1

Page 2: ...23 01 2019 19 26 V11 01 ...

Page 28: ...Description SIMOTICS FD 1LH1 28 Operating Instructions 01 2019 ...

Page 122: ...Operation 8 10 faults SIMOTICS FD 1LH1 122 Operating Instructions 01 2019 ...

Page 140: ...Maintenance 9 2 Corrective Maintenance SIMOTICS FD 1LH1 140 Operating Instructions 01 2019 ...

Page 162: ...Disposal 11 5 Disposal of components SIMOTICS FD 1LH1 162 Operating Instructions 01 2019 ...

Page 164: ...Service and Support SIMOTICS FD 1LH1 164 Operating Instructions 01 2019 ...

Page 168: ...Quality documents SIMOTICS FD 1LH1 168 Operating Instructions 01 2019 ...

Page 173: ......