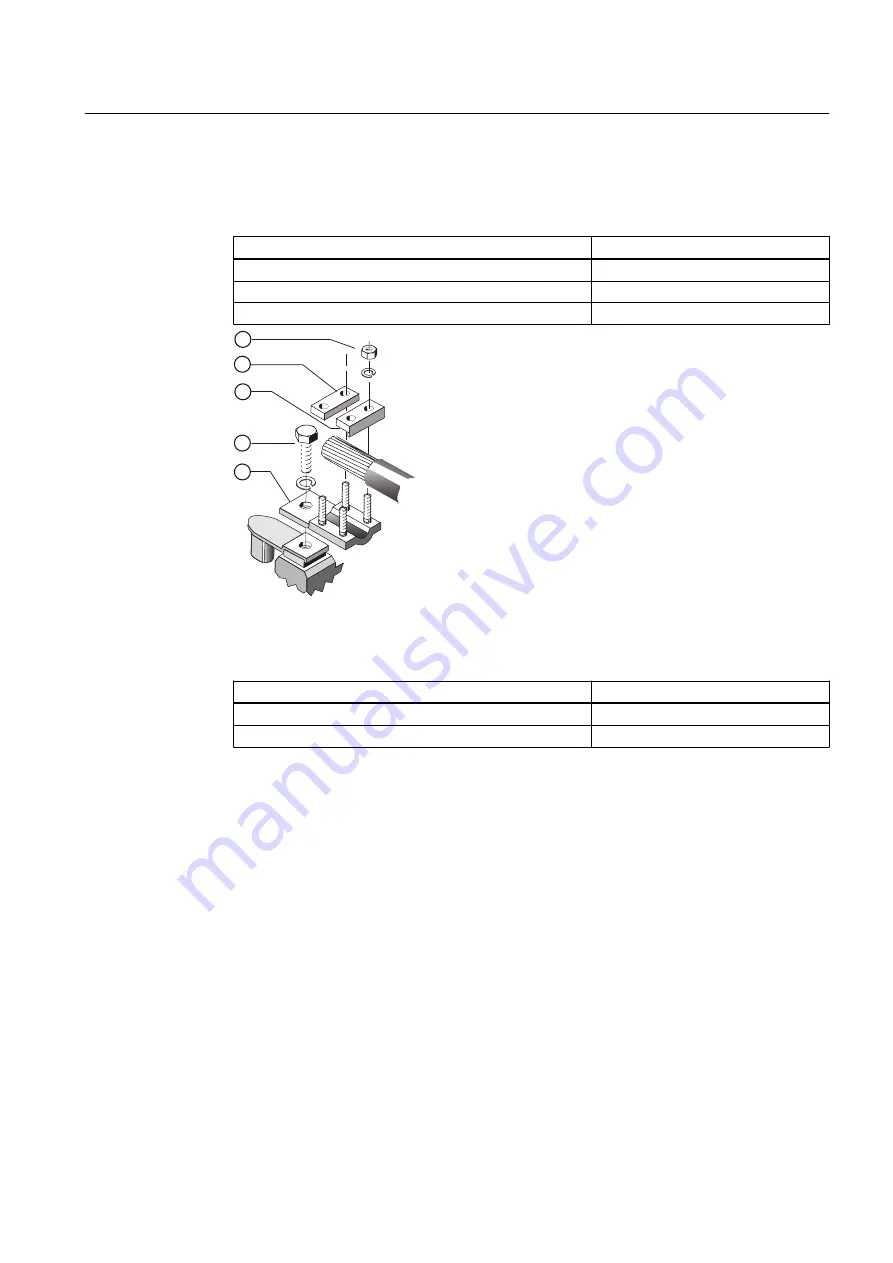

4. Make sure the terminal clamps

③

,

④

are arranged correctly for the size of the conductor.

Insert the cable into the terminal clamps. Tighten the clamping nuts

⑤

to the tightening

torque as specified in the following table.

Terminal box

Tightening torque

GT640 / 1XB1621 / 1XB1631 / 1XB1634

8 Nm

1XB7730 / 1XB7731

4 Nm

1XB7740 / 1XB7750

8 Nm

Figure 6-11

Connection using terminal clamps (schematic diagram)

5. If you have loosened the terminal body clamping bolts

②

, then retighten them with the

following torque:

Terminal box

Tightening torque

1XB1621 / 1XB1631 / 1XB1634

40 Nm

GT640 / 1XB7730 / 1XB7731 / 1XB7740 / 1XB7750

20 Nm

For terminal boxes GT640, 1XB7730 and 1XB7731, fasten the terminal element

①

using a

clamping nut M12 on the threaded stud of the terminal support with a torque of 20 Nm.

Electrical connection

6.5 Inserting and routing the cables

SIMOTICS FD 1LH1

Operating Instructions 01/2019

91

Summary of Contents for SIMOTICS FD 1LH1

Page 2: ...23 01 2019 19 26 V11 01 ...

Page 28: ...Description SIMOTICS FD 1LH1 28 Operating Instructions 01 2019 ...

Page 122: ...Operation 8 10 faults SIMOTICS FD 1LH1 122 Operating Instructions 01 2019 ...

Page 140: ...Maintenance 9 2 Corrective Maintenance SIMOTICS FD 1LH1 140 Operating Instructions 01 2019 ...

Page 162: ...Disposal 11 5 Disposal of components SIMOTICS FD 1LH1 162 Operating Instructions 01 2019 ...

Page 164: ...Service and Support SIMOTICS FD 1LH1 164 Operating Instructions 01 2019 ...

Page 168: ...Quality documents SIMOTICS FD 1LH1 168 Operating Instructions 01 2019 ...

Page 173: ......