Additional tests may also be required according to the system-specific conditions.

NOTICE

Machine damage

When carrying out the inspection, if you detect any impermissible deviations from the normal

state, you must rectify them immediately. They may otherwise cause damage to the machine.

9.1.5

General inspection

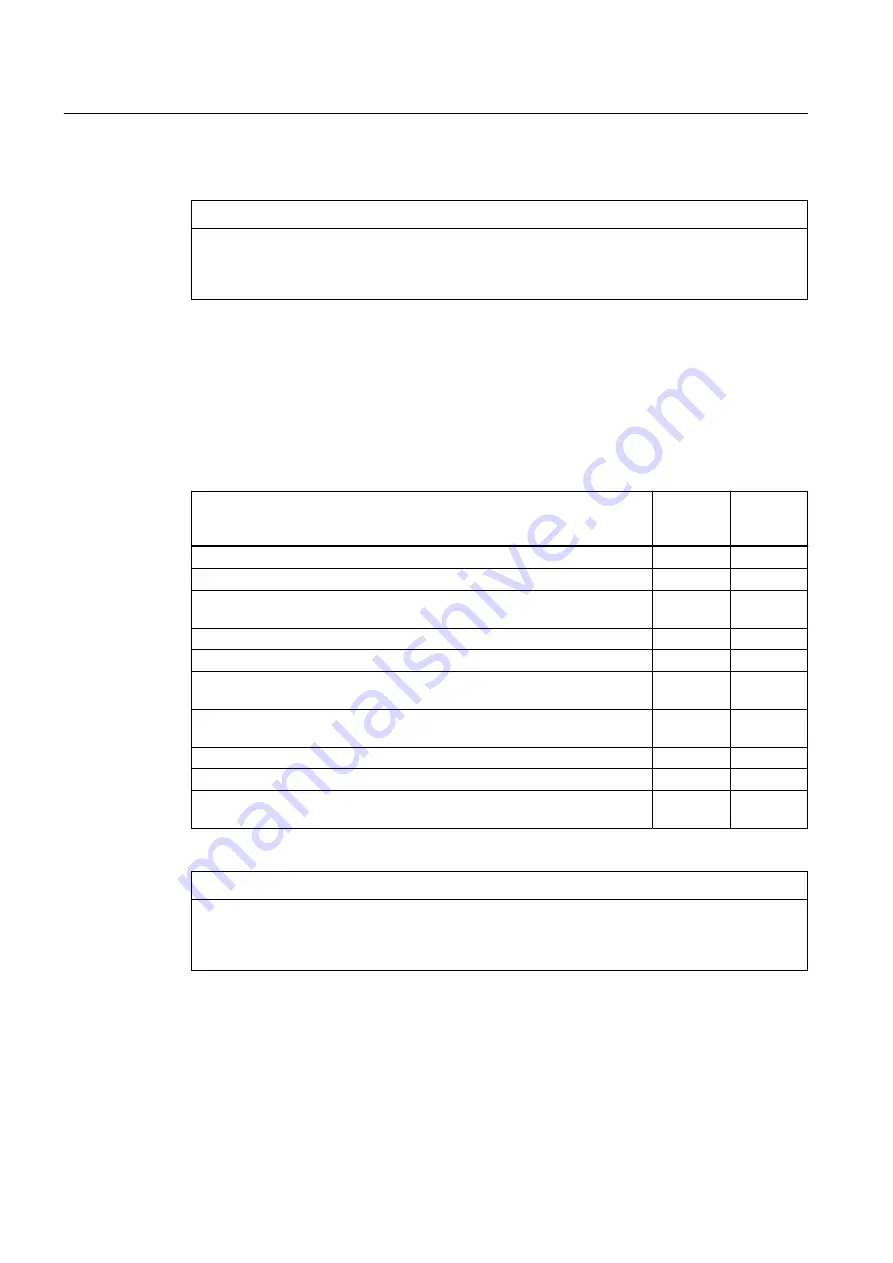

Check that the installation conditions are observed. We recommend that the following checks

are performed after approx. 16 000 operating hours or at the latest after two years:

Table 9-2

Checks that have to be performed during the general inspection

Checking

When the

motor is

running

At stand‐

still

The electrical parameters are maintained

X

The permissible bearing temperatures are not exceeded (Page 101)

X

The smooth running characteristics and machine running noise have not

deteriorated

X

The motor foundation has no cracks and indentations (*)

X

X

The machine is aligned within the permissible tolerance ranges

X

All the fixing bolts/screws for the mechanical and electrical connections have

been securely tightened

X

All the potential connections, grounding connections and shield supports are

correctly seated and properly bonded

X

The winding insulation resistances are sufficiently high

X

Any bearing insulation is fitted as shown on the plates and labels

X

The CABLES and insulating parts and components are in good condition and

there is no evidence of discoloring

X

(*) You can perform these checks while the motor is at standstill or, if required, while running.

NOTICE

Machine damage

When carrying out the inspection, if you detect any impermissible deviations from the normal

state, you must rectify them immediately. They may otherwise cause damage to the machine.

See also

Set values for monitoring the winding temperature (Page 102)

Maintenance

9.1 Inspection and maintenance

SIMOTICS FD 1LH1

126

Operating Instructions 01/2019

Summary of Contents for SIMOTICS FD 1LH1

Page 2: ...23 01 2019 19 26 V11 01 ...

Page 28: ...Description SIMOTICS FD 1LH1 28 Operating Instructions 01 2019 ...

Page 122: ...Operation 8 10 faults SIMOTICS FD 1LH1 122 Operating Instructions 01 2019 ...

Page 140: ...Maintenance 9 2 Corrective Maintenance SIMOTICS FD 1LH1 140 Operating Instructions 01 2019 ...

Page 162: ...Disposal 11 5 Disposal of components SIMOTICS FD 1LH1 162 Operating Instructions 01 2019 ...

Page 164: ...Service and Support SIMOTICS FD 1LH1 164 Operating Instructions 01 2019 ...

Page 168: ...Quality documents SIMOTICS FD 1LH1 168 Operating Instructions 01 2019 ...

Page 173: ......