Image Quality

9 - 5

Siemens AG

SPB7-250.815.02

Page 5 of 20

MAMMOMAT

Novation

DR

Medical Solutions

Rev. 02

09.04

CS SD 24

System

2.

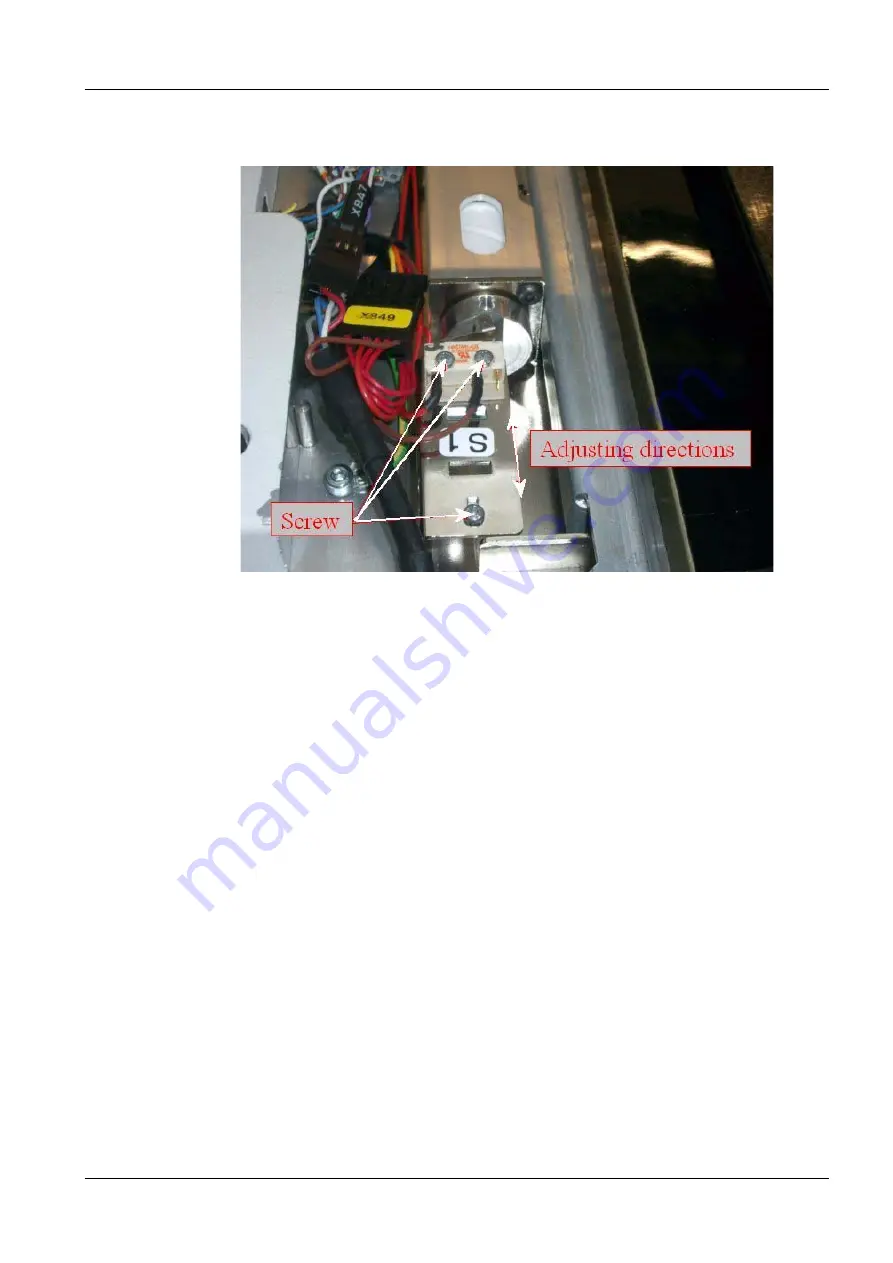

Loosen the three screws. Now it's possible to adjust the grid switch (S1) alongside

the grid (see Fig. 4).

Fig. 4

Adjust grid switch S1