Assembly Instructions

41

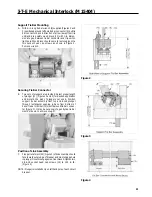

MD and ND-Frame Application

A complete kit consists of handle, cable and breaker operator

The handle can be mounted on either right hand or left hand

flange type enclosures. It can be locked in the OFF position

with up to three padlocks. A two piece door catch is provided

for applications where no interlocking door latch mechanism

is provided. The breaker operator mounts to the circuit

breaker and can be padlocked in the OFF position. The flexible

cable connects the handle to the breaker operator. The

handle operator can be used with I-T-E door latch mecha-

nisms DKR2, DKR3, DKL2. and DKL3.

Mounting

A.

Turn off and lock out supply power before installing the

device.

B.

Determine mounting location for the handle and circuit

breaker (See Figure 1 and Tables 1 and 2.)

Table 1 - Maximum E Dimensions

AAAA

AAAA

AAAA

AAAA

AA

AA

AAAA

AAAA

AAAA

AAAA

AAA

AAA

AAAA

AAAA

AAAA

AAAA

AA

AA

Enclosure Depth

FHONCO48

FHONCO60

0

16

30

2

15.5

29.5

6

15

29.5

18

15.5

29.5

20

16

29

24

15.5

28.5

30

10

26

36

-

23

Table 2 - F Dimensions

AAAA

AAAA

AAAA

AA

AA

AA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

AAAA

A

A

AAAA

AAAA

AAA

AAA

AAAA

AAAA

AA

AA

AAAA

AAAA

AAA

AAA

AAAA

AAAA

AAA

AAA

Enclosur

Depth

48” Cable

60” Cable

Up

Down

Up

Down

10

8

21.5

17.5

31.5

12

7.5

21

18

32.5

16

6.5

21

19

32

18

6

20.5

18.5

32

20

6

20

16.5

31.5

24

4

19

14

31

30

-1.5

15.5

11

28.5

36

-

-

6.5

23.5

Table 2 shows the maximum horizontal distance that the

breaker can be located from the handle. Table 3 shows the

maximum vertical distance the breaker can be located from

the handle. Figure 2 shows the mounting range of the circuit

breaker within the enclosure. NOTE: Minimum Bend Radius

for the Cable is 3 1/2 in.

C.

Drill the mounting holes for the handle and circuit breaker

and file all burrs.

Handle Installation

A.

Push rubber gasket (1) into the groove of the handle

assembly (2) (Figure 3).

B.

The handle and the interlock mechanism (3) are supplied

pre-assembled from the factory (Figure 3).

NOTE: For ease of assembly, move the operating handle to

the ON position (toward top of enclosure).

C.

Mount the frame (4) and handle assembly to the enclo-

sure flange (5) using two 5/16-18 x 3/4 in. button head

cap screws and lockwashers. Tighten cap screws from

within enclosure (Figure 3).

Figure 1

Figure 2

Summary of Contents for I-T-E Sensitrip MD Series

Page 2: ......

Page 6: ...4 I T E Sensitrip Digital Circuit Breaker MD and ND Frame Outline Drawings 1 3 Pole ...

Page 8: ...6 MD and ND Frame Trip Adjustments ...

Page 12: ...10 MD and ND Frame Time Current Curve 600 1000A With Short Time Delay Set on Fixed Time ...

Page 13: ...MD and ND Frame Time Current Curve 11 1200A With Short Time Delay Set on Fixed Time ...

Page 14: ...12 MD and ND Frame Time Current Curve 600 100A With Short Time Delay Set on I2 t ...

Page 15: ...MD and ND Frame Time Current Curve 13 1200A With Short Time Delay Set on I2 t ...

Page 16: ...14 MD and ND Frame Time Current Curve 600 100A Without Short Time Settings ...

Page 17: ...MD and ND Frame Time Current Curve 15 1200A Without Short Time Settings ...

Page 18: ...16 MD and ND Frame Time Current Curve Ground Fault Trip Data ...

Page 19: ...MD and ND Frame Time Current Curve 17 Example ...

Page 20: ...18 MD and ND Frame Let Thru Curves ...

Page 31: ...Installation Diagrams 29 ...

Page 35: ...I T E Mechanical Interlock M15404 33 Figure 7 ...

Page 41: ...Installation Diagrams 39 ...

Page 49: ...Installation Diagrams 47 ...

Page 50: ...48 I T E Panelboard Connecting Straps 1 ...

Page 53: ...Installation Diagrams 51 ...