-21-

SE

TU

P

Model W1807 7

1

⁄

2

HP Heavy-Duty Industrial Tilting Spindle Shaper

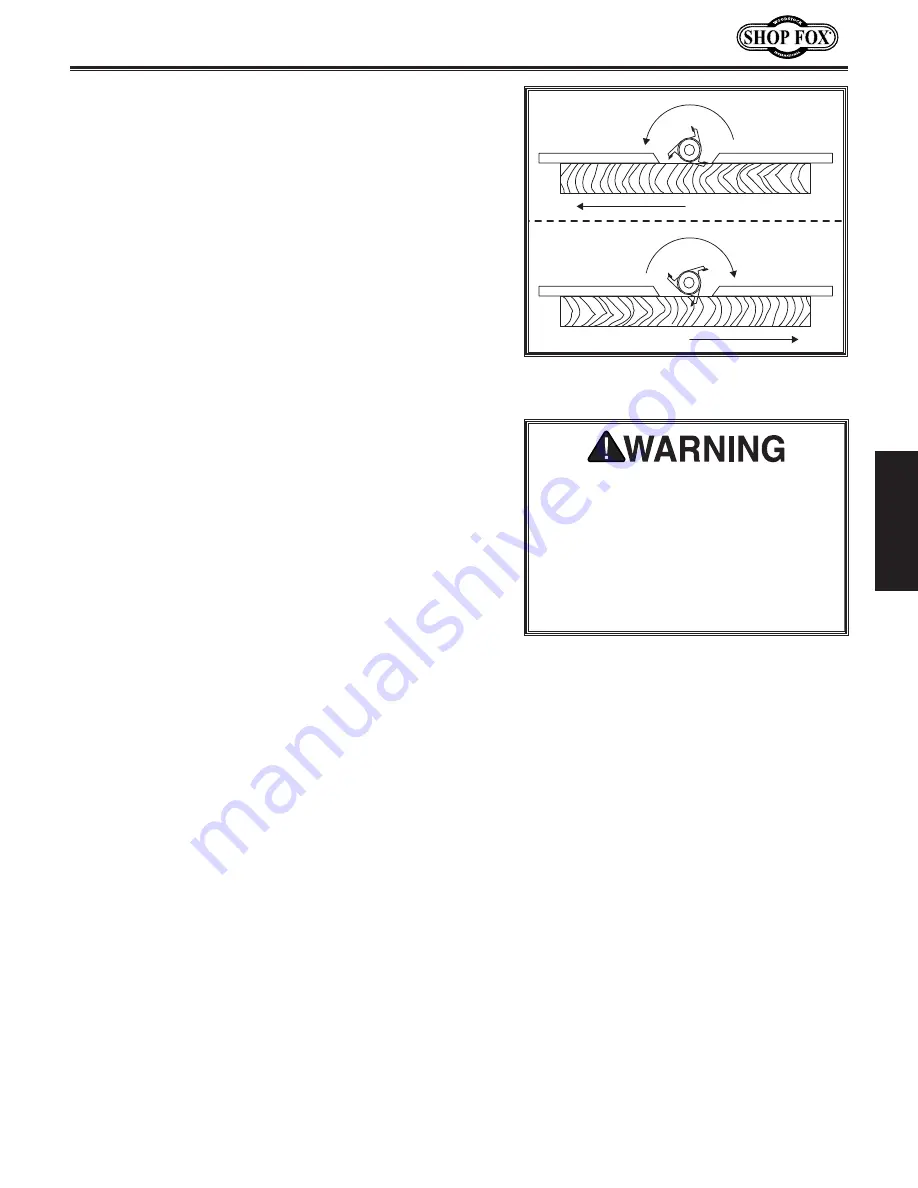

Verifying Spindle Rotation

To operate the shaper safely and reduce the risk of

workpiece kickback, you must verify that the spindle is

rotating in the correct direction as indicated by the for-

ward/reverse switch (see

Figure 14

).

Safely start and stop the shaper. As the spindle slows,

visually verify the rotation direction.

— When the

Fwd

(forward) direction is selected, the

spindle must rotate

counterclockwise

as you look

down on it from above. The workpiece passes the

cutter from right-to-left.

— When the

Rev

(reverse) direction is selected, the

spindle will rotate

clockwise

as you look down on

it from above. The workpiece passes the cutter

from left-to-right.

An incorrect spindle rotation can be resolved by switch-

ing any two hot leads at the power connection. If you are

unsure how to do this, have a qualified electrician do it

for you. If this procedure does not solve the spindle rota-

tion problem, call Tech Support for help.

�������

�����

��������

��������������

�������

�����

��������

��������������

Figure 14.

Illustration of correct spindle

and cutter rotation.

You MUST verify that the spindle rotates

in the expected direction according

the position of the forward/reverse

switch. The workpiece MUST be fed

into the cutter against the rotation of

the cutter. Otherwise, workpiece kick-

back could occur resulting in serious

personal injury.

Summary of Contents for W1807

Page 6: ......

Page 9: ...3 Model W1807 71 2 HP Heavy Duty Industrial Tilting Spindle Shaper INTRODUCTION...

Page 10: ...4 Model W1807 71 2 HP Heavy Duty Industrial Tilting Spindle Shaper INTRODUCTION...

Page 58: ...52 PARTS Model W1807 71 2 HP Heavy Duty Industrial Tilting Spindle Shaper Table Cabinet...

Page 64: ......