Mach-DSP User’s Manual

Document Number: MACH-DSP-9021

Page 60

www.ScannerMAX.com

A final note about using Mode 2…

Although the cable resistance, coil resistance, coil inductance, and Back EMF voltage

may be known, we recommend that these values be fine-tuned using the built-in

oscilloscope, while monitoring Motor I*R (TP84) and Coil Temperature (TP22). Also

note that Mode 2

will not

work properly with the ScannerMAX Compact 506 scanner.

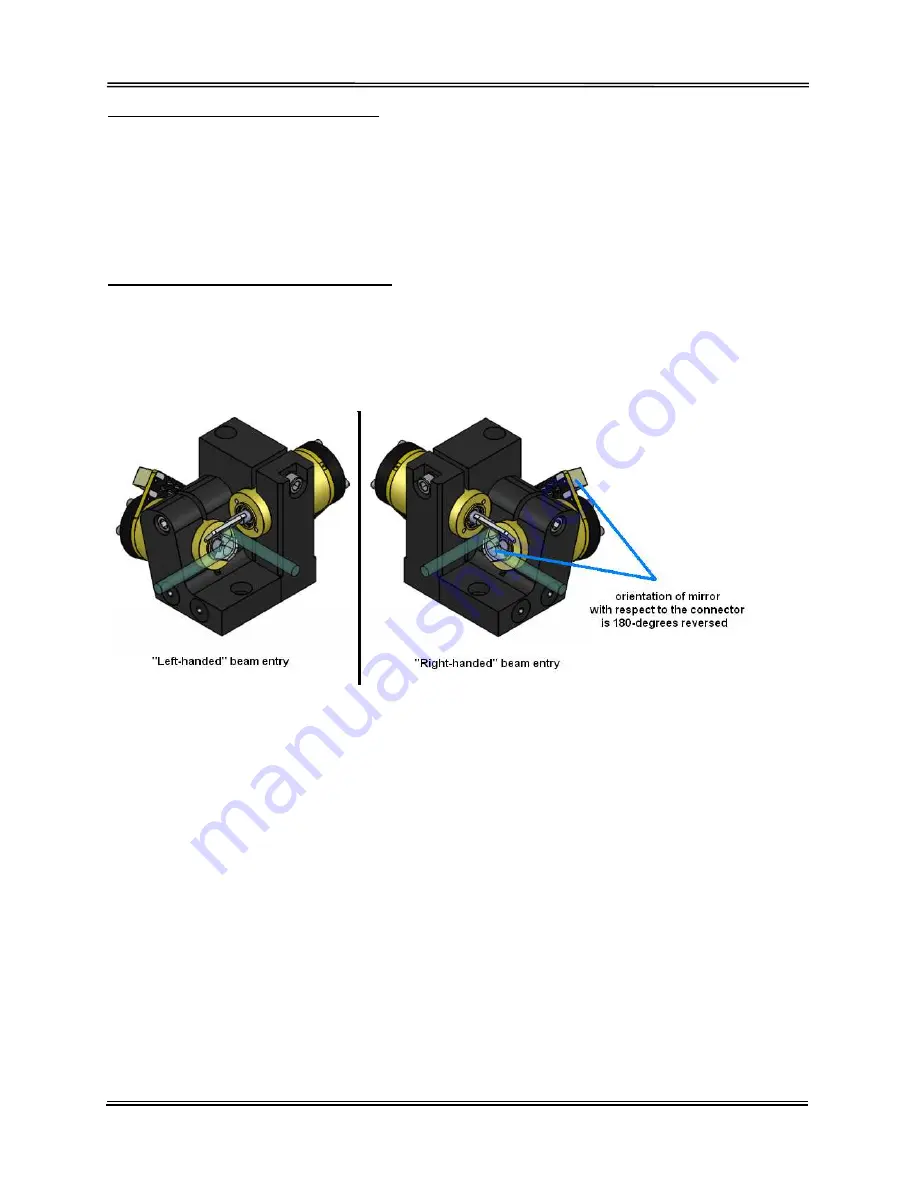

Motor drive (mirror) orientation

Depending on whether you are using an X-Y mount configured for right-handed beam

entry, or left-handed beam entry, the rotational orientation of the X and Y mirrors needs

to change (with respect to the connector on the scanner). See the picture below for

further clarification.

Most manufacturers of galvanometers require you to remove the mirrors from the

scanners and orient the reflective surface of the mirror on the other side of the scanner

shaft itself. This is because other manufacturers of scanners use a “stopping pin” which

prevents the rotor from rotating all the way around.

However, the Compact and Saturn series of scanners manufactured by ScannerMAX

have rotors that can rotate all the way around (a feature used to exercise bearings). For

this reason, accommodating left-handed mounts or right-handed mounts becomes easy,

and is accomplished by merely changing the polarity of the motor drive signal.

The Mach-DSP servo driver allows you to set the motor drive polarity, to accommodate

right-handed or left-handed mirror orientation.

CAUTION! It is recommended that Servo Gain, Low Frequency Damping, Error Integral

Gain and Position-proportional gain all be set to zero, and that any external mirror

bumpers are applied correctly before changing this setting!