27

Keep the manual for future reference - For more informations visit www.saerelettropompe.com

7.3 OPERATIONS NEEDED EVERY 3000 WORKING HOURS

Check:

•

The conditions of the shaft protections: wear rings and bushings;

•

The conditions of the shaft;

•

The conditions of the impeller.

If necessary, replace the components listed above.

7.4 LUBRICATING THE BEARINGS

Il tipo dei cuscinetti è riportato nella documentazione tecnica di riferimento.

Pumps with the bearings permanently lubricated with grease 8version supplied a standard):

the bearings are of the permanently

lubricated type (with grease) and they do not request any maintenance. The intervals of the indicative changing are indicated in the

TAB.VII

(foreseen duration according to L10).

Pumps with oil bath bearing (version supplied upon request)

WARNING!

Pumps with bearings in oil bath are shipped without oil inside. Before starting, the pump must be plugged with the lubricatingoil in

the bearing support.

WARNING!

Use a costant level oiler (supplied on request).

Replenish and top up the oil, through the oiler.

WARNING!

It is oil supplier’s responsibility to indicate an oil with suitable characteristics.

WARNING!

Do not mix different types of oil.

Do not introduce contaminating substances inside the bearing, the support and in the oil.

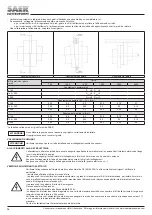

Oil filling procedure

Pour the oil from the cap (1)- Chek that the level arrive to the middle of the control window (red

dot - 4) – This is the necessary quantity of oil for pump operation.

Open the oiler (2) and pour the oil in the overtuned bulb.

Once the bulb (4) is returned to its position, the quantity of oil must be such that, its level in the

oiler is about at the center line of the bearing (3).

This is the level in the oiler only and constitutes the oil reservoir which progressively over time is

consumed.

Characteristics of the oil to be used for the normal working conditions (Tamb.= -10°C – 40°C, Tmax bearings = 110°C) - the following indications are of

general character, for some applications may be necessary oils with higher performance

-

Basic oil: mineral (suggested) or synthetic

-

Viscosity Index– VI min: 95

-

Min. Viscosity Grade ISO VG: 100

-

Working temperature: -10°C / + 170°C

-

Flash point > 200°C

Some types of the oil that are possible to be used

-

AGIP ARUM HT

The relubrication breaks has to be based on the type of use. Approximately every 1000 - 1500 working hours and not less than once a year.

7.5 PUMP DISASSEMBLY

Refer to specific literature, and require it to the manufacturer (section, instructions etc ...)

Execute the pump stop as indicated above.

Before executing any operation, turn off the power and prevent it from being reconnected. Assure that the pump cannot be started

accidentally.

Follow all safety rules, listed in the previous paragraphs and those, pertaining the country where it operates.

The rotating part of the pump, can be removed without removing the pump body from the piping.

Dismantling procedure: see Annex A

Summary of Contents for NCB

Page 60: ...60 1 1 2 2 IEC 60364 4 3 www saerelettropompe com...

Page 62: ...62 SAER EN809 5 5 SAER 40 C 40 C 1000 www saerelettropompe com...

Page 65: ...65 6 9a i ii iii 6 iv v vi 9b i ii 6 iii iv v 1 2 3 40 C 90 C 50 C PN www saerelettropompe com...

Page 66: ...66 30 20 100 10 7 o o 1500 o o www saerelettropompe com...

Page 73: ...73...

Page 75: ...75...