25

Keep the manual for future reference - For more informations visit www.saerelettropompe.com

ELECTRICAL CONNECTION

WARNING!

Set properly the values of the electrical devices (protections, electronic devices etc…).

6. SETTING AT WORK, OPERATION AND STOP

FILLING AND PRIMING THE PUMP

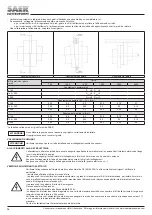

Priming over head (liquid level on the suction side lower than the pump)

(

Fig.9a

)

i. Close the gate valve on the delivery side

ii. Unscrew the venting cap (

Fig.6

)

iii. Fill the pump and the suction side

iv. Make sure that all the air is leaked out from the pump.

v. Once the filling is finished, close completely the caps.

Priming under head (liquid level on the suction side higher than the pump)

(

Fig.9b

)

i.

Close the gate valve on the delivery side

ii.

Unscrew the venting caps (

Fig.6

)

iii.

Open the gate valve on the suction side

iv.

Waiting for the exit of the water from the venting caps.

v.

Once that the water exits without air presence, close the caps

WARNING!

The priming operation must be repeated in case of long periods of inactivity and whenever necessary.

WARNING!

Check the right setting for auxiliary connection:

•

Venting and drain holes must be closed

•

In case there are some flushing lines for the seals, they must be open.

6.2 CHECKING OF THE ROTATION WAY

Remove any lifting device before starting the pump.

Verify that the rotation direction of the electric pump corresponds to that indicated by the arrow on the pump body. Rapidly apply and remove voltage

and observe the rotation direction of the motor cooling fan through the holes of fan guard. In the event that the pump is rotating in reverse, reverse two

phases on the terminal board.

WARNING!

The checking of the rotation way must be repeat every time the motor is connected.

Do the starting as shown in the paragraph Starting

6.3 STARTING

Before starting the group be sure that all the prescriptions and the controls described in the previous paragraphs are respected.

WARNING!

In order to avoid serious damages to the components we recommend:

•

do not leave the pump run without liquid;

•

do not run the pump for a long period with the delivery valve closed;

•

do not run the pump in cavitation.

After having done the electrical connection and the priming:

i.

Fully open the gate valve in suction.

ii.

Keeping the gauge valve closed on the delivery side, feed current, waiting for the pump to reach full operating speed.

iii.

Slowly open the valve on the delivery until you achieve the desired flow rate.

6.4 CHECKS WHILE RUNNING

After a sufficient period of time to reach normal operating conditions, verify that:

•

There are no liquid leaks (for soft packing seal, do reference to the specific section of this manual)

•

There are no vibrations or anomalous noises.

•

There are no oscillations of the flow rate.

•

Ambient temperature does not exceed 40 °C

•

The temperature of the pump body does not exceed 90 °C.

•

The motor’s current absorption does not exceed that shown on the plate.

In the presence of even only one of these conditions, stop the pump and find the cause.

WARNING!

In the event that the surface of the pump is hotter than 50 °C, we recommend protecting it against accidental contact, such as using

grates or shielding, in such a way that however does not affect correct ventilation.

WARNING!

The pump maximum working pressure can’t be bigger than the PN pump nominal pressure.

Summary of Contents for NCB

Page 60: ...60 1 1 2 2 IEC 60364 4 3 www saerelettropompe com...

Page 62: ...62 SAER EN809 5 5 SAER 40 C 40 C 1000 www saerelettropompe com...

Page 65: ...65 6 9a i ii iii 6 iv v vi 9b i ii 6 iii iv v 1 2 3 40 C 90 C 50 C PN www saerelettropompe com...

Page 66: ...66 30 20 100 10 7 o o 1500 o o www saerelettropompe com...

Page 73: ...73...

Page 75: ...75...