28

Keep the manual for future reference - For more informations visit www.saerelettropompe.com

8. DECOMISSIONING AND DISPOSAL

At the end of the operating life of the pump/electropump or any of its parts, it must be disposed of in observance of current regulations.In case you need

to return the material to the supplier :

−

completely empty the pump from the liquid and wash it carefully

−

if necessary, provide for a complete decontamination of the product,

−

remove any liquids or grease residues (lubricants etc …)

−

protect the pump from corrosion and pack it carefully

−

indicate to the supplier any security measure applied

It is the responsibility of who returns the materials to take all measures necessary to ensure the safety of the product and

that the return is in accordance with the regulations of applicable law.

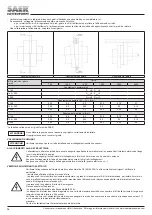

9. TROUBLESHOOTING

FAILURES OR

MALFUNCTIONS

ID

PROBABLE REASONS

REMEDY ACTIONS

! No flow

A.1

→

Wrong direction of rotation

3

Verify the rotation direction of the motor. If correct,

verify the right assembly of the impeller with the pump

body.

A.2

→

Pump not filled with the fluid

3

Fill the pump and the suction pipe, with the fluid.

A.3

→

Air presence in the pump or in the suction

pipeline

3

Verify the possible losses of the pipeline. Breathe the

pump in order to get out the air.

A.4

→

Suction pipeline not enought immersed.

3

Increase the immersion of the suction, that is

sublevelled

A.5

→

Suction head too raised

3

Low the level of the pump

A.6

→

Impeller or suction line clogged.

3

Check any eventual obstuction of the sucton filters and

of the impeller. Remove the obstruction.

A.7

→

Isufficience of the motor rotation speed.

3

Check the motor rotation speed. For motors powered

by inverter, check the feed frequency.

A.8

→

Head of the pumping plant too hight.

3

Check the outlet valves holes. Make a calculation of

the pumping plant and compare it whit the one of the

pump. Use a pump with higher head.

! Insufficient flow rate

→

Reasons already listed on previous points

Consider points: from A.1 to A.7

B.1

→

Cavitation functioning. NPSHa insufficient.

3

Icrease the pumping plant NPSHa, reducing the

suction losses, or approaching the pump to the fluid

that has to be aspirated.

B.2

→

Losses from the seals.

3

Replace the seals

B.3

→

Demaged impellers.

3

Replace the impeller.

B.4

→

Demaged wear rings.

3

Replace the wear rings.

B.5

→

Foot valve too slim

3

Replace the foot valve .

! Outlet pressure too low

→

Reasons already listed on previous points

Consider points: A.1, A.3 ÷ A.7,B.2 ÷ B.4

C.1

→

Outlet line ostructions

3

Remove the ostructions

C.2

→

Pressure gauge wrong positioning

3

Position the outlet pressure gauge on the outlet and the

inlet pressure gauge on the inlet

! High absorbtion

→

Reasons already listed on previous points.

3

Consider points: A.1, B.1 ÷ B.3

D.1

→

Usury or mechanical seizure

Check and, where necessary, replace seals, bearings

and wear rings.

D.2

→

Functioning out of performance curves.

The head is lower than the minimum head

allowed

3

Act on the outlet regulation valve to increase the head

and low the flow rate.

D.3

→

Excessive tightening of the soft packing.

3

Relax the tightening of the soft packing.

D.4

→

Excessive speed of the motor speed rotation.

3

Check the corrispondence between motor speed and

pump. When the motor is powered by inverter, low the

frequency

D.5

→

Fluid density / viscosity higher then of the

contractual ones

3

Low the flow rate. Call the technical assistance

D.6

→

Misalignment between pump and motor

3

Check and realign pomp and motor.

D.7

→

Motor problems

3

Refer to motor informations.

! Vibrations or high noise

→

Reason already listed on previous points.

3

Consider points: a3-a6, b1,b3-b4,d1,d2,d3, d5,d6, d7

E.1

→

Pump, motor o basament not properly setted

3

Check the tightening of all anchor bolts

E.2

→

Pipeline misaligned or imposed on the pump

3

Support the pipes checking their alignment with the

pump.

E.3

→

Damaged bearings

3

Replace the bearings

Summary of Contents for NCB

Page 60: ...60 1 1 2 2 IEC 60364 4 3 www saerelettropompe com...

Page 62: ...62 SAER EN809 5 5 SAER 40 C 40 C 1000 www saerelettropompe com...

Page 65: ...65 6 9a i ii iii 6 iv v vi 9b i ii 6 iii iv v 1 2 3 40 C 90 C 50 C PN www saerelettropompe com...

Page 66: ...66 30 20 100 10 7 o o 1500 o o www saerelettropompe com...

Page 73: ...73...

Page 75: ...75...