21

Keep the manual for future reference - For more informations visit www.saerelettropompe.com

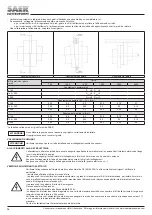

Handling of the bare shaft pump

To lift the pump, harness it as shown in the picture

Fig. 3

, by passing the ropes around the bearing supports.

Do not attach lifting devices to the shaft end of the pump. The angle of pull must not be greater than 90°

Handling of the complete set

Set with total load up to 1500 kg: Sling the group as in

Fig. 4

or, if present, use the holes or lifting pins made in the basement.

Set with total load higher than 1500 kg: it is not recomended to lift the complete set assembled. Lift the single components (pump, motor, coupling,

base). In case it is necessary to enliven the entire group, proceed like in

Fig. 4

.

Do not attach lifting devices to the shaft end of the pump or to the eybolts of the motor. The angle of pull must not be greater than

90°

STORING

WARNING!

Storage conditions: store the pump / set in a covered and dry place, lacking dust, freeze and vibrations.

Storage temperature= min 0°C - max 50°C

Metallic exposed surfaces (shaft ends, flanges) must be protected in a suitable way to prevent corrosion.

If you plan to store the pump or the complete set, for a long period of time (more than one month), it is necessary to perform the

following operations monthly:

•

verify that the preservation status of the pump / complete set and paying more attention to the non-painted surfaces;

•

check with the appropriate tools, the free rotation of the shaft;

•

check the condition of lubricating bearings.

•

Once a month, rotate shaft by hand, in order to keep the bearings protected by the lubricant.

•

For versions with oil lubricated bearings: fill the oil chamber to the brim. During the put on use, drain the oil and fill the

chamber up to the appropriate level.

For any problem replace or recondition the damages parts prior the use.

4. TECHNICAL SPECIFICATIONS AND USE

PRODUCT DESCRIPTION

NCB:

End-suction centrifugal pump with dimension according to EN733

NCBK:

End-suction centrifugal pump with dimension exceeding EN733

NCBZ / NCBKZ

: complete set with pump and motor coupled together by mean of an elastic coupling, on a base plate.

The pump / electric pump’s identification and technical data are listed on the name plate which certify the conformity to CE norms

(Fig. 1

). In case of pump

and motor assembled, a name plate will state for the hydraulic part and another one for the motor; in case of pumps sold without motor, there will be the

name plate with the hydraulic data only.

WARNING!

In case of a bare shaft pump, the useful output power provided by the motor must be above the power absorbed by the pump.

Do not use the pump for rotating speeds higher than those indicated on the data plate.

General technical features

End suction centrifugal single-stage pump (ESOB with axial suction)

“Back pull out” system: the hydraulic part can be removed without removing the pump body from the piping.

Horizontal or vertical installation (with suction downwards).

NCB Series: dimension according to EN733

Radially splitted pump body with integrated feet.

Closed impeller with several rooms.

Ball bearings, permanent grease lubrication (standard) o in oil bath (optional)

Shaft seal system:

o

NCB Series: mechanical seal according to EN12756 (standard), soft-packing (optional)

o

NCBK Series: soft-packing (standard), mechanical seal according to EN12756 (optional).

For motor features refer to the motor manual.

USE – STANDARD VERSIONS

Pumping of clean liquids and without solid bodies , for civil , industrial and agricultural uses. Use the pump / electric pump only for the purposes described

in this manual. Any other use can be a cause of accidents.

For the special versions, refer to the specific technical literature (technical data, drawings, etc. ...).

Limitation for use

Passing of solids: max 2 mm.

Max working time with closed delivery: 2 min.

Temperature of the pumped liquid: min -15°C max 120°C (90° with soft-packing, standard).

Max starts / h equally distributed: Refer to the motor instruction manual

Maximum working pressure: refer to pump name plate

Max ambient temperature: 40°C

Summary of Contents for NCB

Page 60: ...60 1 1 2 2 IEC 60364 4 3 www saerelettropompe com...

Page 62: ...62 SAER EN809 5 5 SAER 40 C 40 C 1000 www saerelettropompe com...

Page 65: ...65 6 9a i ii iii 6 iv v vi 9b i ii 6 iii iv v 1 2 3 40 C 90 C 50 C PN www saerelettropompe com...

Page 66: ...66 30 20 100 10 7 o o 1500 o o www saerelettropompe com...

Page 73: ...73...

Page 75: ...75...