22

Keep the manual for future reference - For more informations visit www.saerelettropompe.com

For applications in firefighting equipment follow all the requirements of the UNI 12845 or applicable local regulations.

The pumps requested and built for pumping potable water should only be used for this purpose. Verify that the pump is suitable for this application

according to the requirements of local regulations. For such applications, the pumps should be cleaned before their first commissioning and after the

replacement of one or more components that come into contact with the pumped liquid. SAER is not liable for contamination caused by transport, storage,

installation or arising from the system on which the pump is installed. For correct installation and use, follow the requirements of local regulations.

Never use the pump for operating pressures higher than those indicated on the data plate.

NOT FORESEEN AND IMPROPER USES

Don’t use the pump/electric pump for applications not covered from EN 809 standard.

Never use the electric pump in explosive atmospheres, hazardous area or to pump inflammable or dangerous liquids.

Don’t use the electric pump with liquids whose density is bigger than the water one (mixtures) or with different chemicals characteristics

from those of the water ones (demineralized or treated water, food liquids, dangerous liquids, ecc..) unless you have contacted the

customer care before.

Don’t use the pump in case of abnormal pressure (ex: water hammer)

Avoid dry operation of the pump.

It is forbidden to use the pump / electric pump in case of damages or anomalous operations.

Always use the pump with a delivery (flow and head) included in the working diagram.

Pumps already used to pump toxic or harmful liquids or other liquids other than potable water may not be used for pumping water

intended for human consumption.

Please refer to the motor instruction manual for others limitation of use and safety warnings

PREVENTION OF FORESEEABLE MISUSE

WARNING!

Always use the pump with a delivery (flow and head) included in the working diagram. Do reference to the name plate and the

technical documentation.

Do not operate the pump under the minimum head.

Do not use the pump beyond the limits specified.

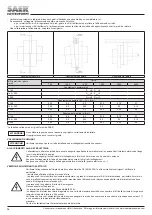

5. INSTALLATION

Never use the electric pump in explosive atmospheres, hazardous area or to pump inflammable or dangerous liquids.

For the classification of the risky places, refer to local regulations .

Use suitable means for lifting and transporting the pump / electricpump.

Before executing any operation, turn off the power and prevent it from being reconnected.

PRELIMINARY VERIFICATIONS

WARNING!

Verify that the data shown on the plate, and in particular, power, frequency, voltage, absorbed current, are compatible with the

characteristics of the electric line or current generator available. In particular, the voltage of the line voltage can have a variance of ±

5% from the nominal voltage value on the plate.

Verify that the protection and insulation grade indicated on the plate are compatible with the environmental conditions.

Verify that the chemical/physical characteristics of the liquid to be moved correspond to those specified on the order.

Verify that the pump has not been exposed to the weather inclemency.

Verify the environmental conditions: SAER pumps can be installed in enclosed or, at any rate, protected areas, with maximum

ambient temperature of + 40 °C in a non-explosive atmosphere.

Contact the customer care in case of ambient tempe40°C or altitude over 1000m above sea level.

The connection to the water supply must be done in the respect of the local and national standards of the place where the pump is

installed.

Verify that the pump’s flow rate and head correspond to the required characteristics.

Before connecting the pipes to the relative openings, make sure that the rotating part of the pump turns freely and is not hindered.

In case of problems please contact our technical assistance servicing.

Summary of Contents for NCB

Page 60: ...60 1 1 2 2 IEC 60364 4 3 www saerelettropompe com...

Page 62: ...62 SAER EN809 5 5 SAER 40 C 40 C 1000 www saerelettropompe com...

Page 65: ...65 6 9a i ii iii 6 iv v vi 9b i ii 6 iii iv v 1 2 3 40 C 90 C 50 C PN www saerelettropompe com...

Page 66: ...66 30 20 100 10 7 o o 1500 o o www saerelettropompe com...

Page 73: ...73...

Page 75: ...75...