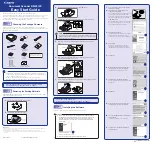

System installation 2-7

F.

Position a second piece of masking tape on the SP2-1 probe

[6] directly above the ‘RENISHAW SP1-2’ label [7].

G.

Looking at the front of the machine tool, position the SP2-1

probe [6] up against the clutch assembly [4] such that the

‘RENISHAW SP2-1’ label [7] is directly facing you and the

probe’s X,Y axes are visually aligned to those of the machine.

Maintaining the probe in this exact position, mark a vertical line

on the masking tape attached to the probe such that it is

directly adjacent that previously marked on the masking tape

attached to the clutch assembly.

H.

Withdraw the SP2-1 probe [6] from the clutch assembly [4].

I.

Remove shank/clutch assembly [4] from the machine tool.

J.

Remove shank from clutch assembly [4].

K.

Remove anodised ring [3] from clutch assembly [4].

L.

With the SP2-1 probe [6] held vertically, place the insulation

washer [5] on top face of probe and align holes.

M.

Assemble the clutch assembly [4] to the top face of the SP2-1

probe [6] ensuring that the two lines you have marked exactly

align.

N.

Maintaining the alignment between the clutch assembly [4]

and the SP2-1 probe as closely as possible, assemble the

anodised ring [3] into the recess within the clutch assembly.

Ensure that the 5mm grubscrew housed within the flange of

the anodised ring locates within the location bore provided

within the top face of the SP2-1 probe [6].

O.

Secure the clutch assembly [4] to the SP2-1 probe [6] with the

three M4 capscrews [2]. Torque capscrews to 2.6 Nm.

P.

Remove masking tape from the SP2-1 probe [6] and clutch

assembly [4].