Chapter 4

34

Envizio Pro and Envizio Pro II Installation and Operation Manual

CAN Troubleshooting

Although the control algorithm is located within the CAN node, all of the same troubleshooting techniques that

are used in a traditional hard-wired or serial control systems still apply to a CAN system and the behavior of the

system remains the same. Flow and speed sensors, as well as the control valve and boom valves, are used in

the same fashion.

CAN Node Off-line Errors

Occasional reports have been received on Raven consoles sporadically losing communication with one or

more CAN nodes. The most likely causes for this problem are:

1.

Corroded and/or open connections in the circuit.

2.

Computer and/or CAN node logic power and grounds connected to a “dirty” power source (dirty power is

defined as any circuit with a variable load that exceeds 1 ampere). This is especially true of circuits loaded

by electrical coils.

3.

Computer and/or nodes connected to different power and/or ground sources. This can result in components

operating at different voltage planes.

Below are some common causes for communication failures:

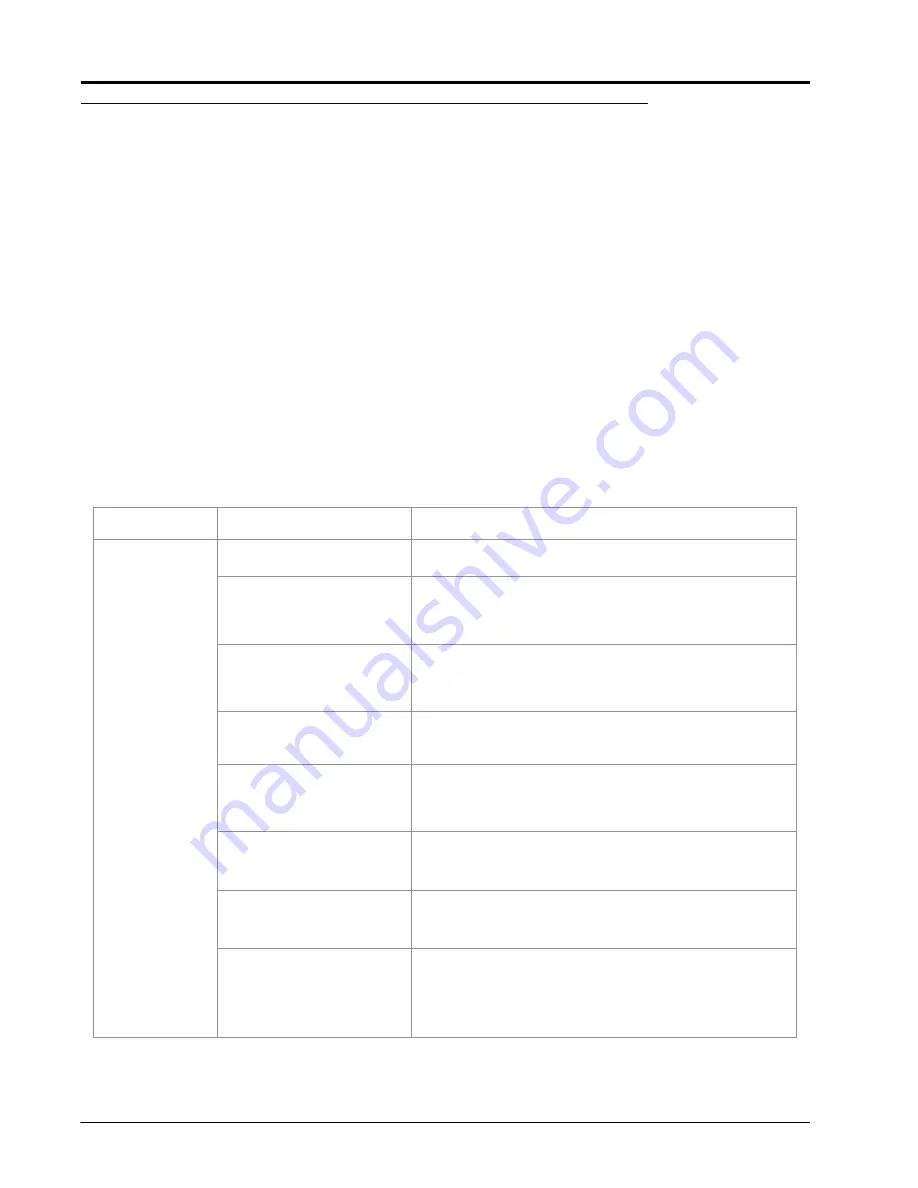

Issue

Possible Cause

Solution

CANbus cannot

read the product

node

• The node is not connected to

the CANbus

• Connect the node and re-initialize the field computer to read

the product node.

• Node is not properly powered

• Connect the clean power - 16 gauge red wire and high current

power - 12 gauge red wire from the product node to a 12V DC

power source that is capable of supplying power to all nodes

connected to the CANbus system

• Node is not properly

grounded

• Connect the clean ground - 16 gauge white wire and the high

current ground - 12 gauge white wire to a good, quality ground

source. Raven recommends grounding the wires to the

negative terminal of the battery.

• The boom/speed node share

power and ground

connections

• Make sure that each node has a separate power and ground

connection.

• CANbus ends not terminated

• Make sure that both ends of the CANbus system are properly

terminated. Refer to the

Raven CANbus Network Installation

Manual

for information on properly terminating the CANbus

network.

• Corroded pins in CANbus

connections

• Check CANbus cable connectors for any highly corroded pins.

• Ensure dielectric grease has been applied to all cable

connections exposed to weather and field conditions.

• Moisture in connection

• Check CANbus cable connectors for any corroded pins.

• Ensure dielectric grease has been applied to all cable

connections exposed to weather and field conditions.

• Connectors not seated

properly

• Check that all CANbus cable connectors are inserted fully

(until the locking tab is engaged).

• Be sure to remove any moisture in connections which were

not properly seated. Check for corroded pins and apply

dielectric grease when reconnecting CANbus cables.

Summary of Contents for Envizio Pro

Page 1: ...Software Version 3 2 Envizio Pro Envizio Pro II Installation Operation Manual...

Page 36: ...Chapter 3 26 Envizio Pro and Envizio Pro II Installation and Operation Manual...

Page 148: ...Chapter 7 138 Envizio Pro and Envizio Pro II Installation and Operation Manual...

Page 158: ...Chapter 8 148 Envizio Pro and Envizio Pro II Installation and Operation Manual...

Page 174: ...Chapter 9 164 Envizio Pro and Envizio Pro II Installation and Operation Manual...

Page 178: ...Chapter 10 168 Envizio Pro and Envizio Pro II Installation and Operation Manual...

Page 184: ...Chapter 11 174 Envizio Pro and Envizio Pro II Installation and Operation Manual...

Page 210: ...Appendix D 200 Envizio Pro and Envizio Pro II Installation and Operation Manual...

Page 230: ...Index 220 Envizio Pro Envizio Pro II Installation Operation Manual...