2-1

2 Printer Operation

2.1

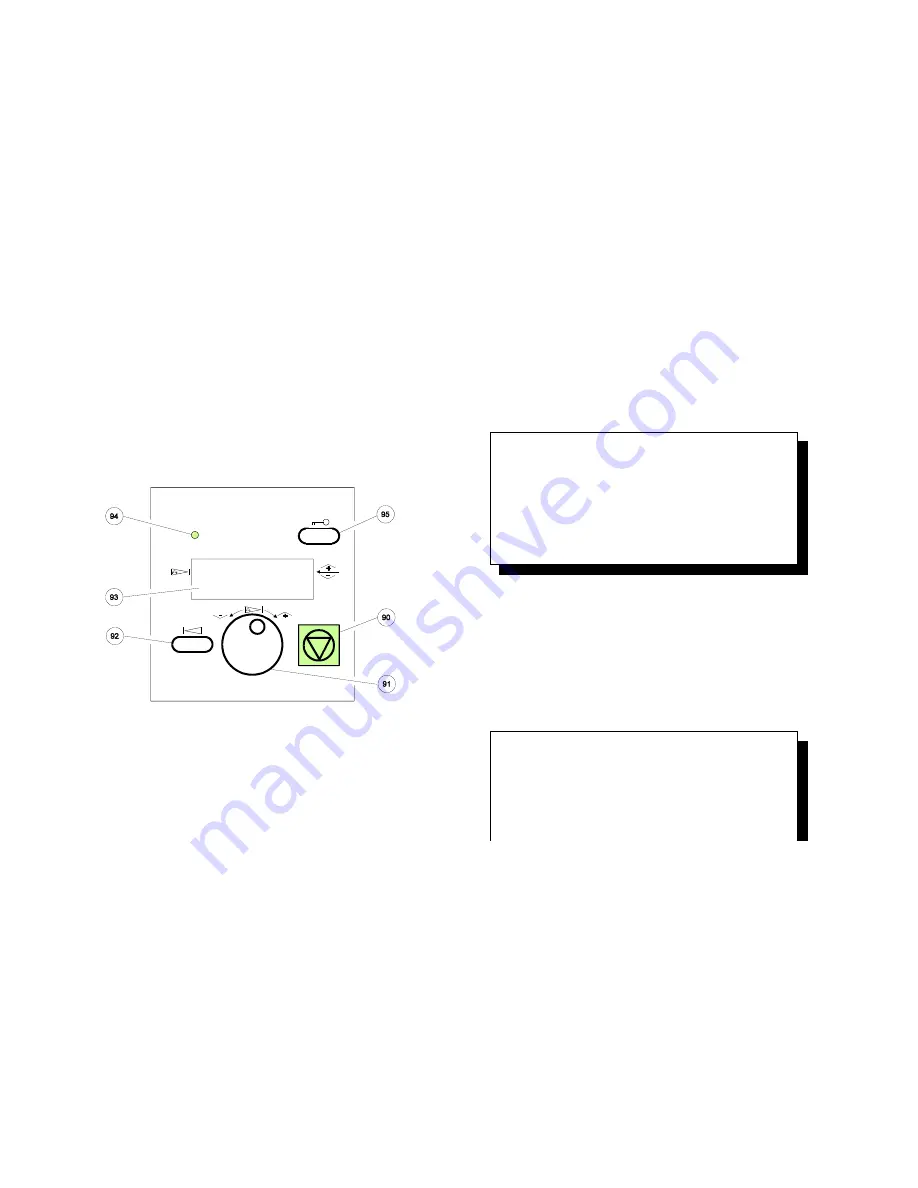

Control Panel

The control panel

S

gives information about the printer status

S

controls various parameter settings

S

allows manual control of the paper handling

2.1.1 Description of the two Indicators

S

The 4-line Liquid Crystal Display (LCD)

(93) indicates the current status of

the printer. If any error occurs (e.g. COVER OPEN) the resulting error

message will be displayed. While configuring the printer menu settings and

parameters appear on the display.

S

The green indicator lamp

(94) is lit if the printer is supplied with power by

setting the power ON/OFF switch to ON.

Printer Operation

2-2

2.1.2 Description of the LCD Indicator

The LCD Indicator gives information about the status of the printer.

In general it can be distinguished between:

S

ONLINE messages

S

OFFLINE messages

When the printer is in the

ONLINE

mode the display shows:

O N L

I

N E

(

1

)

1

6

.

0

0

x

1

2

I

N C H

L O W E R

-

-

> B O T T O M

In line two the selected paper format is shown and in line three the selected

paper input and paper output.

Note:

The value after

ONLINE

is the indication of the actual

PROFILE

.

When the printer is in the

OFFLINE

mode status information, error messages,

or menu messages are displayed.

Example: The display content after paper jam.

Note:

The printer status gets OFFLINE when a failure occurs.

O F F

L

I

N E

(

1

)

1

6

.

0

0

x

1

2

I

N C H

L O W E R

-

-

> B O T T O M