4.2.6

Protection settings and Output Limit Info

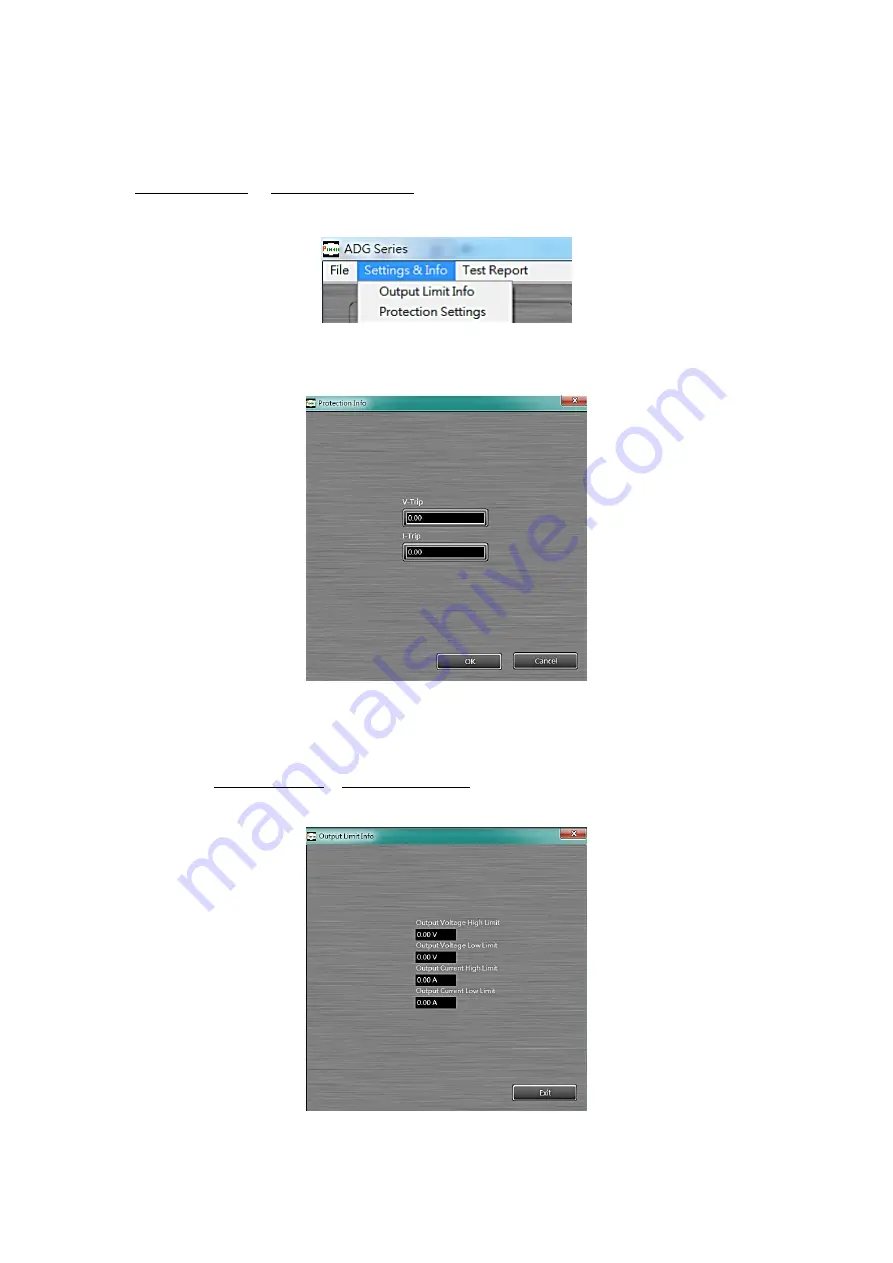

The user is able to set the protection point for overvoltage and overcurrent: go to

Settings & Info

→

Protection Settings

on the menu bar. The set value of protection

point is within the range of 5-115% of the rated value

Figure 4.22 Path to the Protection setting

Figure 4.23 Protection setting page

The user is able to review the output limit of the remotely connected ADG-P series

unit: go to

Settings & Info

→

Output Limit Info

on the menu bar.

Figure 4.24 Output Limit Info page