Magnum C3C Spreader Sprayer

Operator Manual

Refer to the cover page for restrictions regarding

Page 38

reproduction or disclosure of this material.

Septenber/08

SPREADER CALIBRATION, ADJUSTMENT, AND OPERATION (continued)

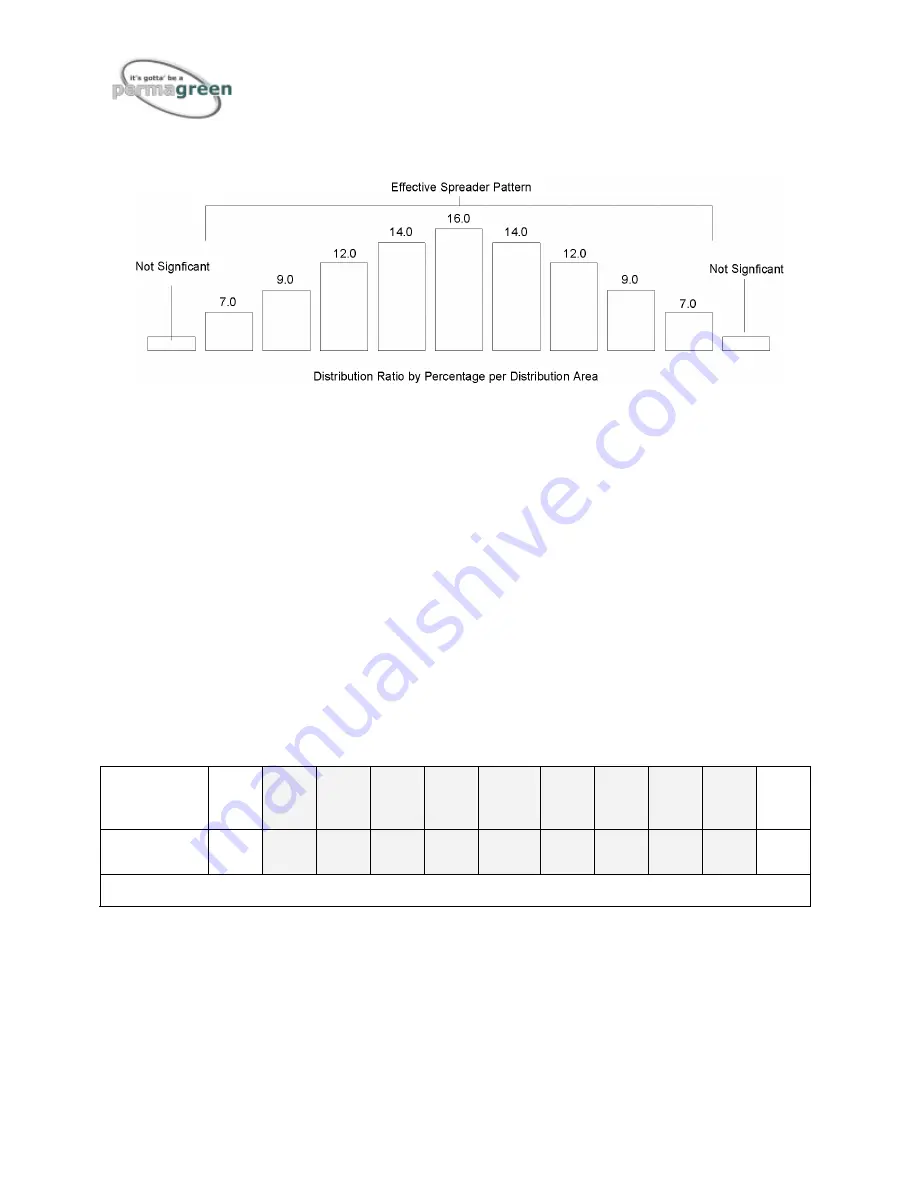

Figure 8. Spreader Material Distribution Ratio

b. Pour the contents of the first pan on your far left into the graduated cylinder or clear

tube. Measure and record the material deposited (refer to Table 1). Dump the

collected pellets back into the bag or hopper. Repeat this measurement for each pan,

one by one, until all eleven pans are emptied and recorded.

c. Add together all eleven recorded numbers to find the total amount of material caught

in the pans.

d. Divide the amount caught in each pan by the total amount. This is the percentage

caught in each pan.

e.

The distribution ratio should be approximately equal to that shown graphically in

Figure 8, and by percentage in Table 1, with the shaded area of the table the most

important. The unshaded area of the pattern receives negligible product distribution.

NOTE: The distribution pattern shown in Figure 8 and Table 1 represents the ideal

pattern, which may not be reproducible in the field.

Pan

number,

from left

1

2

3

4

5

center

6

7

8

9

10

11

Material

percentage

*

7

9

12

14

16

14

12

9

7

*

*Amount Not Significant

Table 1. Material Distribution Ratio by Percentage

f. To adjust the distribution pattern for the right side, move the lever as necessary to

increase or decrease the opening in the adjustment hole. Reset the memory lock.