5-6

5.1.6

93B

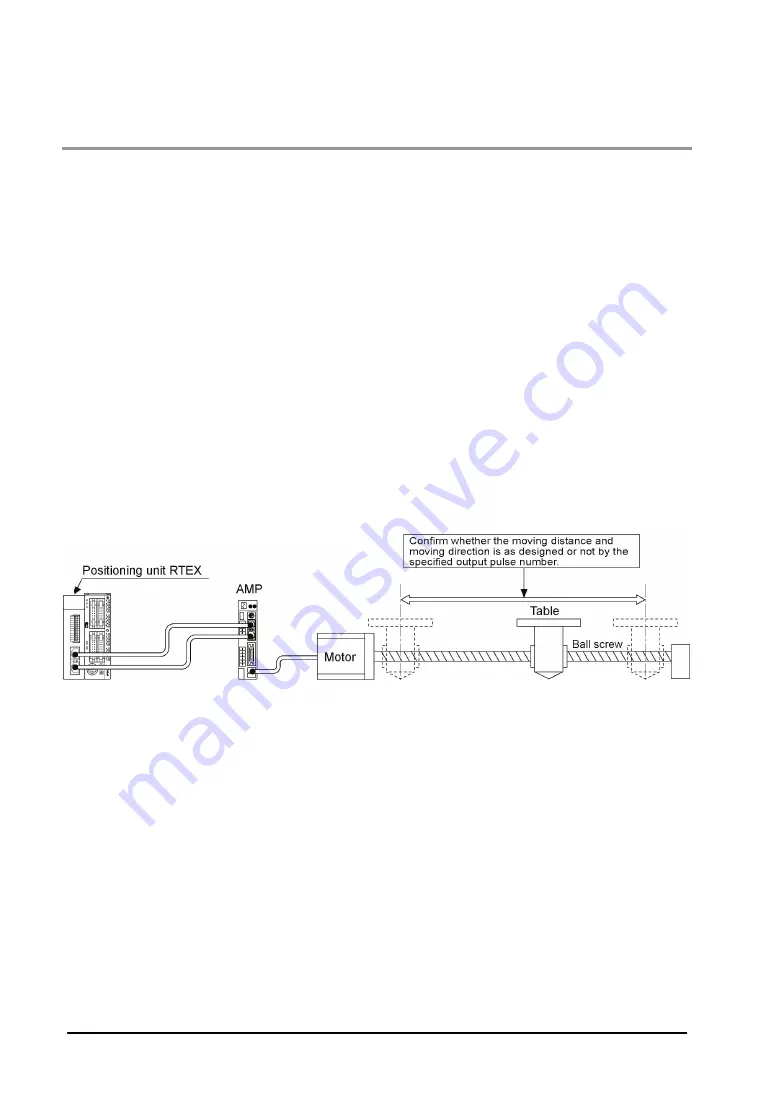

Procedure 5: Checking Rotating and Moving Directions and Moving

Distance

Check whether the rotating and moving direction of the motor and the moving distance is correct or not.

The operations can be easily confirmed using the tool operation function of the Configurator PM without

ladder programs.

1. Confirm the rotating direction and moving direction of the motor by the JOG operation. Select the

“Online”

→

“Tool operation” on the menu of the Configurator PM, and make the servo on for the

corresponding axis to execute the JOG operation. When using the ladder program, turn on the forward

JOG and reverse contact after turning on the servo on contact.

The rotating direction is determined according to the installation of the ball screw or the “CW/CCW

direction setting” of the parameter.

2. Confirm whether the moving distance is as designed or not by the position control. Set the table 1 of

the positioning data using the Configurator PM, and select the “Online”

→

“Tool operation” on the

menu of the Configurator PM after downloading the table to the positioning unit RTEX, and make the

servo on for the corresponding axis to execute the JOG operation. When using the ladder program,

set the position control starting table, and then turn on the positioning start contact after turning on the

servo on contact.

The moving distance is determined according to the pitch of the ball screw, deceleration gear rate or

setting movement amount of the positioning data.

Note) Execute the servo on, and make the AMP under the condition that the servo is locked before

performing the JOG operation and position control.

Summary of Contents for FP2 Positioning Unit RTEX

Page 1: ......

Page 6: ...iv ...

Page 14: ...xii ...

Page 15: ...Chapter 1 Functions of Unit and Restrictions on Combination ...

Page 21: ...Chapter 2 Parts and Functions ...

Page 22: ...2 2 2 1 Parts and Functions FPΣ Positioning Unit RTEX FP2 Positioning Unit RTEX ...

Page 24: ...2 4 ...

Page 25: ...Chapter 3 Wiring ...

Page 31: ...Chapter 4 Power On Off and Items to Check ...

Page 36: ...4 6 ...

Page 37: ...Chapter 5 4BPreparation For Operation ...

Page 45: ...Chapter 6 5BI O Allocation ...

Page 53: ...Chapter 7 6BSetting Tool Configurator PM ...

Page 83: ...7 31 Setting Font Select Option Font in the menu bar The following dialog is shown ...

Page 102: ...7 50 ...

Page 103: ...Chapter 8 7BAutomatic Operation Position Control ...

Page 118: ...8 16 ...

Page 119: ...8 17 When the X axis and Y axis is the moving axes each axis in the above diagram is replaced ...

Page 141: ...Chapter 9 8BManual Operation JOG Operation ...

Page 146: ...9 6 ...

Page 147: ...Chapter 10 9BManual Operation Home Return ...

Page 155: ...Chapter 11 10BManual Operation Pulser Operation ...

Page 159: ...Chapter 12 11BStop Functions ...

Page 162: ...12 4 ...

Page 163: ...Chapter 13 12BSupplementary Functions ...

Page 177: ...13 15 Sample program When reading AMP parameter No 1 1 of axis 1 with A6N or A5N ...

Page 179: ...13 17 Sample program When writing AMP parameter No 1 1 of axis 1 with A6N or A5N ...

Page 183: ...Chapter 14 Precautions During Programming ...

Page 187: ...Chapter 15 Errors and Warnings ...

Page 212: ...15 26 ...

Page 213: ...Chapter 16 Troubleshooting ...

Page 214: ...16 2 16 1 Cannot Communication With AMP ...

Page 215: ...Chapter 17 Specifications ...

Page 275: ...Chapter 18 Dimensions ...

Page 276: ...18 2 18 1 FPSigma Positioning Unit RTEX ...

Page 277: ...18 3 18 2 FP2 Positioning Unit RTEX ...

Page 278: ...18 4 ...

Page 279: ...Chapter 19 Sample Programs ...

Page 283: ...19 5 ...

Page 286: ...19 8 ...

Page 288: ......