Operating instructions for Pool control-40.net filter control unit

Page: 13 (34)

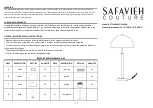

Fit the mini float switch on the sliding bracket. Then fasten the fixing rail

vertically on the skimmer wall at the approximate height required for the

water level. You can then set the water level by moving the sliding

bracket up and down the rail. Tighten the screw to fasten the sliding

bracket in place. All the parts fit easily inside each other so no great force

is needed.

Use without level control

If you do not want to use the built-in level control, you must select the option Level control - type: skimmer pool

in the configuration menu.

Solenoid valve for topping up the water level

A normally closed solenoid valve must be used for the water intake. This valve must be

connected to terminals U9 / N of the control unit. A suitable solenoid valve (R

½

"), part

number 1090005804, is available from the

range.

Temperature sensor

The sensors can be

connected either way

round (polarity not

important).

Pool temperature sensor

Connect the swimming-pool temperature sensor to terminals 29 and 30. The

temperature sensor is supplied as standard with a cable length of 1.5m. If

required, this can be extended to a maximum length of 20m using a twin-core

cable (min. cross-section 0.5mm²). Avoid running the sensor lead close to mains

cables to prevent potential interference.

Since precise temperature control can only be achieved with good heat transfer

between the temperature sensor and swimming pool water, an

R1/2"

thermowell (part no. 320.020.0003) must be fitted in the piping system.

skimmer wall

float

float

switch

connecting

lead

fixing rail

sliding

bracket

waterlevel

securing ring

screw

-thermowell