7

Item

Content

Common

Control Method

I/O Control

RS-485 Communication

Network converter connection

Modbus RTU protocol connection

Position Command Input

Setting with operating data number Command range for each point:

−

8388608

∼

8388607 [steps] (Setting Unit: 1 [step])

Speed Command Input

Setting with operating data number Command Range: 0

∼

1000000 [Hz] (Setting Unit: 1 [Hz])

Acceleration/Deceleration

Command Input

Set with the operating data number or parameter.

Command Range: 0.001

∼

1000.000 [ms/kHz] (Setting Unit: 0.001 [ms/kHz])

Return-

To-Home

Operation

Return-to-Home Modes

2-Sensor Mode

A return-to-home operation that uses a limit sensor (

+

LS,

−

LS).

3-Sensor Mode

A return-to-home operation that uses a limit sensor and home sensor.

Position Preset

A function where P-preset is input at the desired position to confirm the

home position.

You can set the home position to the desired value.

Positioning

Operation

Number of Positioning

Points

63 points (No. 1

∼

63)

Operating Modes

Incremental mode (Relative positioning)

Absolute mode (Absolute positioning)

Operation Functions

Independent Operation

A PTP (Point to Point) positioning operation.

Linked Operation

A multistep speed-change positioning operation that is linked with

operating data.

Linked Operation 2

A positioning operation with a timer that is linked with operating data.

The timer (dwell time) can be set 0

∼

50.000 [sec].

(Setting Unit: 0.001 [sec])

Start Methods

Operating Data Selection Method

Starts the positioning operation when START is input after selecting

M0

∼

M5.

Sequential Method (Sequential

positioning)

Starts the positioning operation in sequence from operating data No. 1

each time START is input.

Continuous

Operation

Number of Speed Points

63 points (No. 1

∼

63)

Speed Change Method

Change the operating data number.

Other

Operations

JOG Operation

Execute regular feed by inputting

+

JOG or

−

JOG.

■

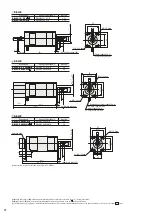

System Configuration

Because the driver has the information necessary for actuator operation, the burden on the host PLC is reduced.

The system configuration when using multi-axis control has been simplified.

Settings are configured using a control module (sold separately), data setting software or RS-485 communication.

■

Operation Types

In the

built-in controller type, the operating speed and traveling amount of the actuator are set with operating data, and operation

is performed according to the selected operating data.

There are 4 operation types.

Basic Setting

(Factory Setting)

Operation Data Setting

Parameter Changing

Data Setting

Test Operation

Alarm History

Parameter Changing

Monitoring

Data Copying

Control Module

(

OPX-2A

)

Driver

Actuator

or

Data setting software (

MEXE02

)

●

Settings using RS-485 communication are also available.

●

The data setting software can be downloaded from the Oriental Motor

website. Oriental Motor can also provide a CD-ROM for free.