43

Fe

a

tu

re

s

H

o

w to R

e

a

d

S

p

e

cif

ications

T

a

ble

Sy

st

e

m

Configur

a

tion

Specifications and

Dimensions

Stan

d

a

rd

T

y

p

e

Specifications and

Dimensions

Gu

id

e

T

y

pe

Specifications and

Dimensions

Ta

b

le

Ty

p

e

Gen

e

ra

l

S

p

e

cif

ications

Specifications, Dimensions,

Connections

Dri

ve

r

Combination

List

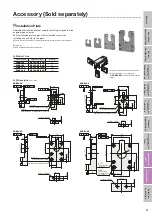

A

c

ces

s

or

ies

Sele

c

tion

ca

lculation

●

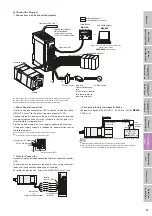

Connection Diagram

◇

Connections with Peripheral Equipment

GND

+

24 V

FG

Included with product.

Sold separately as accessories.

Connect to the driver with the communications cable

for data setting software

CC05IF-USB

(sold separately).

or

Programmable Controller

or Master Equipment

Connect when controlling

with RS-485

communications.

Programmable Controller

Actuator

Connected to CN6

or

CN7

Connected to

CN3

Connected to

CN2

✽

2

Connected to

CN4

✽

1

DC Power Supply

Noise Filter

Use as protection against

noise.

This is effective for reducing

noise generated from the

power supply and driver.

AC

Power Supply

Control Module

OPX-2A

(Sold separately)

Data Setting Software

MEXE02

✽

1 When the product or the driver is purchased, it comes with a 0.6 m connection cable.

✽

2 When the product or the driver is purchased, it comes with a 1 m connection cable.

●

Keep the wiring distance between the actuator and driver to 10 m max..

◇

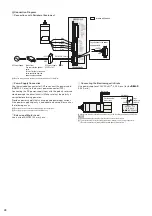

Power Supply Connection

Use the included connector for CN1 to connect the power cable

(AWG22: 0.3 mm

2

) to the driver's power connector (CN1).

Connecting the DC power-supply input with the polarity reversed

would damage the driver (circuits). Make sure that the polarity is

correct before turning power on.

Provide a power supply that can supply adequate input current.

If the power supply capacity is inadequate, abnormalities such as

the following occur.

●

The actuator does not operate normally in high-speed operation.

●

The actuator does not accelerate or decelerate as set.

FG

GND

24 VDC

Power Supply

Connector for CN1

(Included)

Power Connector (

CN1

)

◇

Actuator Connection

Connect using the included connection cable (for actuator connector,

CN4).

The terminals and connectors required for connecting the motor

leads and the connection cable are not included.

For motor lead extension, use a wire of AWG22 (0.3 mm

2

) min.

Motor Leads

or

Connection Cable (Included)

Connection Cable

(Included)

Actuator

Connector (

CN4

)

Blue

Red

Orange

Green

Black

Blue

Red

Orange

Green

Black

◇

Connecting the Electromagnetic Brake

Use power supplies of 24 VDC±5%

✽

, 0.25 A min. (for the

DRL42

,

0.08 A min.)

Surge

Suppressor

(Included)

Switch

Black/White

Red/White

24 VDC

±

5%

✽

0.25 A

min.

(

DRL42

:

0.08 A

min.)

Motor Leads

Electromagnetic

Brake Leads

✽

If the wiring distance is extended by 20 m or more, the specification becomes 24 VDC

±

4%.

Notes

●

Applying voltage exceeding the specifications causes actuator failure.

●

To protect the switch contacts and prevent noise, always connect a surge suppressor.

(The surge suppressor is included with electromagnetic brake motors.)