62

EN

Symptoms

Location to investigate

Solution

The output torque is low

Screws cannot be

tightened

Are you using a combination of

Nitto Kohki measuring devices for

measurement?

Use a combination of Nitto Kohki's measuring

devices for measurement. (p. 5)

Are you turning the torque adjustment

ring clockwise?

Has the output torque dropped?

The output torque decreases as the tool is used.

Turn the torque adjustment ring clockwise. (p. 17)

Did you check the correlation between

the output torque occurred on screws

and the output torque measured using

a measurement device?

The output torque occurred on screws and the

output torque measured by the measurement device

are different.

Adjust the output torque according to the screw

fastening conditions. (p. 5)

Is the bit worn out?

When the bit is worn out, it becomes difficult to

transmit torque to screws.

Replace the bit. (p. 9)

Are you tightening while crushing a

part between the screws.

Has regression loosening occurred?

Torque may not be transmitted. Crush the part once

and then tighten the screw.

Auto reverse mode is in effect. (p. 28)

Has axial force occurred to the screw?

Without axial force, even though the output torque

is increased, screws are not tightened. Review the

screw fastening conditions.

Also, by tightening at low speed, it becomes easier

to transmit torque.

Has initial loosening occurred?

Initial loosening occurs as a result of permanent set

in fatigue when fine irregularities such as surface

roughness are lost over time after the screw is

tightened or outside force is applied. Tighten the

screw again.

When using auto reverse mode, torque reaches the

set torque once, thus it is more effective than single

tightening. (p. 28)

Has the permanent set in fatigue

occurred due to permanent

deformation of sealing material such

as the gasket?

Carefully check the screw fastening conditions and

set the output torque and rotation level.

Depending on the material, torque may not be

transmitted if a screw is tightened at high speed.

Is the area surrounding the screw at a

high temperature?

Screws could be extended or loosened by

temperature changes.

Review the screw fastening conditions and process.

Have you considered the occurrence

of vibration or outside force?

Loosening of screw occurs if no measures are taken

for vibration or outside force.

Take appropriate loosening prevention measures.

The output torque is high

Screws are tightened

too much

Did you check the correlation between

the output torque occurred on screws

and the output torque measured using

a measurement device?

The output torque occurred on screws and the

output torque measured by the measurement device

are different.

Adjust the output torque according to the screw

fastening conditions. (p. 5)

Have you attached a heavy jig or a jig

having a large radius at the end?

After the torque reaches the set torque, the inertial

force of the jig might have been transmitted to

screws.

Review the jig and reduce the weight or size of the

jig.

The torque scale and

output torque do not

match

The torque scale is a standard. The output torque range is not guaranteed.

The output torque range sometimes differs from the scale but this is not a product error.

(p. 7)

The electric screwdriver

gets hot

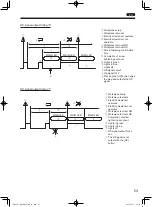

Is the ON time of the electric

screwdriver too long?

Alternatively, is the OFF time too

short?

Review the operation time.

The rated operating time is 0.5 sec. ON and 3.5 sec.

OFF.

Aim at 15 screws per minute. (p. 5)

Even though the output torque is set

to the specification lower limit value,

does the screwdriver get hot to a level

where you cannot touch it?

When the output torque becomes higher, the electric

screwdriver becomes hot.

If it gets hot to a level where you cannot touch even

with the specification lower limit value, a failure is

suspected.

TV07521-1_DLV30S12P-AYK_en.indb 62

2017/02/10 15:56:38