EN

English –

3

3.2

.1

- Product durability

The lifetime is the average economic duration of the product. The value of life-

time is strongly influenced by the intensity of the manoeuvres, i.e. the sum of all

factors that contribute to product wear (see

Table 3

).

To estimate the lifetime of your automation, proceed as follows:

01.

Add the values of the items in

Table 3

regarding the system conditions;

02.

In

Graph 1

from the value obtained above, trace vertical line until it inter-

sects the curve; from this point trace a horizontal line until it intersects the

line of the “manoeuvre cycles”. The obtained value is the estimated lifetime

of your product.

The lifetime values specified in the graph are only obtainable if the maintenance

schedule is strictly observed (see chapter “Maintenance schedule”). The esti-

mation of lifetime is made on the basis of design calculations and the results of

tests performed on prototypes. As it is only an estimation, it does not represent

any form of guarantee on the effective lifetime of the product.

Example of durability calculation: automation of a gate with a door 4.5 m long

with a weight of 250 Kg, installed near the sea:

Table 3 shows the “severity index” for this type of installation: 10% (“Door length”),

15% (“Door weight”) and 15% (“Presence of dust, sand or salt”).

These indicators must be added together to obtain the overall severity index, which

is in this case 40%. With the value identified (40%), look at the horizontal axis of

Graph 1 (“severity index”), and identify the value corresponding to the number of

“manoeuvre cycles” our product will be able to perform in its lifespan, about 105,000

cycles.

TABLE 4 - Technical specifications of electric cables

Connection

Cable type

Maximum admissible length

A

:

Power line

N°1 cable 3 x 1,5 mm

2

30 m (

note 1

)

B

:

Flashing light with aerial

N°1 cable 2x0,5mm

2

20m

N°1 RG58 type shielded cable

20m (recommended less than 5 m)

C

:

Photocells

N°1 cable 2x0,5mm

2

30m (

note 2

)

D

:

Key-operated selector switch

N°2 cables 2x0,5mm

2

(

note 3

) 50m

E

:

Fixed edges

N°1 cable 2x0,5mm

2

(

note 4

) 30m

F

:

Movable edges

N°1 cable 2x0,5mm

2

(

note 4

)

30m (

note 5

)

Note 1

– power supply cable longer than 30 m may be used provided it has a larger gauge, e.g. 3x2,5mm

2

, and that a safety grounding system is provided

near the automation unit.

Note 2

– If the “BLUEBUS” cable is longer than 30 m, up to 50 m, a 2x1mm

2

cable is needed.

Note 3

– A single 2x0,5mm

2

cable can be used instead of two 4x0,5mm

2

cables.

Note 4

– Please refer to Chapter “7.3.2 STOP Input” in situations where there is more than one edge, for information about the type of connection recom-

mended by the manufacturer.

Note 5

– special devices which enable connection even when the leaf is moving must be used to connect movable edges to sliding leaves.

CAUTION!

– The cables used must be suited to the type of environment of the installation site.

0

10 20 30 40 50 60 70 80 90 100

20.000

40.000

60.000

80.000

100.000

120.000

140.000

160.000

180.000

200.000

220.000

240.000

260.000

GRAPH 1

Severity index %

Durability in cycles

Surrounding temperature greater than

40°C or lower than 0°C or humidity

greater than 80%

Presence of dust, sand and salinity

Set motor power to “level 4”

20%

15%

15%

TABLE 3

Severity index %

< 3 m

3 - 4 m

4 - 5 m

5 - 6 m

< 200 kg

200 - 300 kg

300 - 400 kg

0%

5%

10%

20%

0%

15%

30%

Leaf length m

Leaf weight Kg

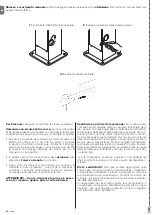

3.3 - Preliminary installation set-up work

Fig. 2

provides an example of an automation system, produced using

Nice

components:

a

Key-operated selector switch

b

Photocells on post

c

Photocells

d

Main fixed edge (optional)

e

Main movable edge

f

“Open” stop bracket

g

Rack

h

Secondary fixed edge (optional)

i

Flashing light with incorporated aerial

l

Naked

m

“Closed” stop bracket

n

Secondary movable edge (optional)

These parts are positioned according to a typical standard layout. With ref-

erence to

fig. 2

, locate the approximate position for installation of each com-

ponent envisaged in the system.

Important

– Before installation, prepare the

electric cables required for the system, with reference to

fig. 2

and “

Table 4

-

Technical specifications of electric cables

”.

Caution

– When laying the ducting for routing the electrical cables, also take

into account that due to possible deposits of water in the routing ducts, the

connection pipelines must not create condensate in the control unit, with con-

sequent damage to the electronic circuits.

Summary of Contents for Naked Sliding NKSL400

Page 2: ......

Page 43: ...I 405 mm 131 mm 135 mm 1 3 4 5 b d c c h l b f m g i n e a E C F D C F A B 2...

Page 44: ...II b a b a c 5 mm 6 7 10 11 8 9...

Page 46: ...IV 14 15...

Page 48: ...VI 19 20 a b c d e...

Page 49: ...VII 21 22...

Page 50: ......

Page 51: ......