EN

2

– English

1.2 - Warnings for installation

• Prior to installing the drive motor, check that all mechanical components

are in good working order and properly balanced, and that the automation

moves correctly

• If the gate or door being automated has a pedestrian gate, then the system

must include a control device that will inhibit the operation of the motor when

the pedestrian gate is open.

• Make sure that the control devices are kept far from moving parts but

nonetheless in a visible position. Unless a selector is used, the control devi-

ces must be installed at a height of at least 1.5 m and must not be accessi-

ble.

• That windows, having a gap exceeding 200 mm when open, are to be closed

using a biased- off switch if the opening movement is controlled by a fire-sen

-

sing system.

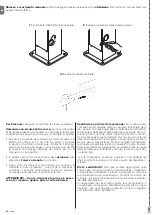

• Ensure that entrapment between the driven part and the surrounding fixed

parts due to the opening movement of the driven part is avoided.

• Permanently fix the label concerning the manual release adjacent to its actua

-

ting member.

• After installing the drive motor, make sure that the mechanism, protective

system and all manual manoeuvres operate properly.

This product is intended for use to automate sliding gates for residential use; it

is a retractable gearmotor which may be installed in a column.

IMPORTANT!

– All uses other than the intended use described and use in environmental

conditions other than those described in this manual should be conside-

red improper and forbidden!

Naked combines an electronic control centre with a finger joint. Electrical con-

nections with external devices are simplified thanks to use of the “BlueBUS”, a

technique permitting connection of multiple devices with only 2 wires.

If powered from the grid, Naked can host a buffer battery (mod. PS124, optio-

nal accessory) which permits the automation mechanism to continue to perform

a number of manoeuvres even in the event of a black-out. In the event of a

blackout, it is still possible to move the gate by releasing the gearmotor using

the key provided (see point 3.7); or you may use the optional accessory: PS124

buffer battery permitting a number of manoeuvres even in the absence of grid

power.

The automation mechanism permits installation of various accessories to add

functions and improve security.

PRODUCT DESCRIPTION AND

INTENDED USE

2

3.1 - Pre-installation checks

Important!

- The installation of NAKED must be carried out by qualified

personnel in compliance with current legislation, standards and regula-

tions, and the directions provided in this manual.

Before proceeding with the installation of NAKED you must:

•Check that all the materials are in excellent condition, suitable for use and that

they conform to the standards currently in force.

• Make sure that the structure of the gate is suitable for automation.

• Make sure that the weight and dimensions of the leaf fall within the spe cified

operating limits provided in chapter “3.2 Operating limits”.

• Check that the force required to start the movement of the leaf is less than

half the “maximum torque”, and that the force required to keep the leaf in

movement is less than half the “nominal torque”. Compare the resulting val-

ues with those specified in Chapter “8 Technical Characteristics”. The manu

-

facturers recommend a 50% margin on the force, as unfavourable climatic

conditions may cause an increase in the friction.

• Check that the internal dimensions of the column are appropriate (at least

140 x 140 mm).

• Check the seats prepared for fixing the column.

• Check that there is enough space in the area at the back inside the column

to insert the gearmotor, pass the cables through and connect them.

• Check that the column is correctly earthed in the installation.

•

Important!

– Make sure that the column has been prepared correctly in

compliance with local legislation and guarantees a protection of at least IP44

when the lid is closed.

• Make sure that there are no points of greater friction in the opening or closing

travel of the gate leaves.

• Make sure there is no danger of the gate derailing.

• Make sure that the mechanical stops are sturdy enough and that there is no

risk of the deformation even when the leaf hits the mechanical stop violently.

• Make sure that the gate is well balanced: it must not move by itself when it is

placed in any position.

• Make sure that the area where the gearmotor is fixed is not subject to flood

-

ing. If necessary, mount the gearmotor raised from the ground.

• Make sure that the installation area enables the release of the gearmotor and

that it is safe and easy to release it.

• Make sure that the mounting positions of the various devices are protected

from impacts and that the mounting surfaces are sufficiently sturdy.

• Components must never be immersed in water or other liquids.

• Keep NAKED away from heat sources and open flames; in acid, saline or

potentially explosive atmosphere; this could damage NAKED and cause mal-

functions or dangerous situations.

• If there is an access door in the leaf, or within the range of movement of the

gate, make sure that it does not obstruct normal travel. Mount a suitable

interblock system if necessary.

• Connect the gate to the protective earth in accordance with current legisla-

tion.

• Provide a device on the electrical power line ensuring complete disconnection

of the automation mechanism from the grid. The disconnection device must

have contacts with an opening distance large enough to permit complete

disconnection under the conditions sanctioned by overvoltage category III,

in accordance with installation regulations. The device ensures quick, safe

disconnection from the power supply if needed, and must therefore be posi-

tioned in view of the automation mechanism. If, on the other hand, it is loca-

ted in a position which is not visible, there must be a system for preventing

accidental or unauthorized reconnection with the power grid to prevent this

risk. The disconnection device is not supplied with the product.

3.2 - Operating limits

Chapter 8 “Technical Characteristics” provides the only data needed to deter-

mine whether the products of the NAKED line are suitable for the intended

application.

The structural characteristics of NAKED make it suitable for use on sliding leaves

in conformity with the limits indicated in tables 1 and 2.

The effective suitability of NAKED to automate a particular sliding gate depends

on the friction as well as other correlated factors, such as ice, that could inter-

fere with the movement of the leaf.

For an effective control it is absolutely vital to measure the force necessary to

move the leaf throughout its entire run and ensure that this is less than half

of the “nominal torque” indicated in chapter 8 “Technical characteristics” (a

50% margin on the force is recommended, as unfavourable climatic conditions

may cause an increase in the friction); furthermore, it is necessary to take into

consideration the data indicated in tables 1 and 2 to establish the number of

cycles/hour, consecutive cycles and maximum speed allowed.

The length of the leaf makes it possible to determine both the maximum num-

ber of cycles per hour and consecutive cycles, while the weight makes it pos-

sible to determine the reduction percentage of the cycles and the maximum

speed allowed. For example if the leaf is 5 m long it will be possible to have

23 cycles/hour and 11 consecutive cycles. However, if the leaf weighs 350

Kg, they must be reduced to 50%, resulting in 11 cycles/hour and 5 consecu-

tive cycles, while the maximum speed allowed is V5: “very fast”. The control

unit has a limiting device which prevents the risk of overheating based on the

load of the motor and duration of the cycles. This device triggers when the

maximum limit is exceeded. The manoeuvre limiting device also measures the

ambient temperature reducing the manoeuvre further when the temperature is

particularly high.

INSTALLATION

3

NKSL400 - Limits in relation to the length of the leaf

Leave width (m)

max. cycle/hour

max. no. of consecutive cycles

Up to 4

35

14

4 ÷ 6

23

11

TABLE 1

NKSL400 - Limits in relation to the weight of the leaf

Leaf weight (kg)

% cycles

Maximum speed allowed

Up to 200

100%

V6 = Extremely fast

200 ÷ 400

50%

V5 = Very fast

TABLE 2

Summary of Contents for Naked Sliding NKSL400

Page 2: ......

Page 43: ...I 405 mm 131 mm 135 mm 1 3 4 5 b d c c h l b f m g i n e a E C F D C F A B 2...

Page 44: ...II b a b a c 5 mm 6 7 10 11 8 9...

Page 46: ...IV 14 15...

Page 48: ...VI 19 20 a b c d e...

Page 49: ...VII 21 22...

Page 50: ......

Page 51: ......