EN

English –

1

ENGLISH

1.1 - General Warnings

ATTENTION!

– Important safety instructions. Follow all instructions as

improper installation may cause serious damage.

ATTENTION!

– Important safety instructions. It is important for you to

comply with these instructions for your own and other people’s safety.

Keep these instructions.

• Before commencing the installation, check the “Technical characteristics” (in

this manual), in particular whether this product is suitable for automating your

guided part. If it is not suitable, DO NOT continue with the installation.

• The product cannot be used before it has been commissioned as specified in

the chapter on “Testing and commissioning”.

ATTENTION!

– According to the most recent European legislation, the

implementation of an automation system must comply with the harmo-

nised standards provided by the Machinery Directive in force, which

enables declaration of the presumed conformity of the automation.

Taking this into account, all operations regarding connection to the

electricity grid, as well as product testing, commissioning and mainte-

nance, must be performed exclusively by a qualified and skilled tech

-

nician!

• Before proceeding with the installation of the product, check that all the mate-

rials are in good working order and suited to the intended applications.

• This product is not intended to be used by persons (including children) whose

physical, sensory or mental capacities are reduced, or who lack the necessary

experience or skill.

• Children must not play with the appliance.

• Do not allow children to play with the fixed control devices of the product.

Keep the remote controls away from children.

ATTENTION!

– In order to avoid any danger from inadvertent resetting of

the thermal cutoff device, this appliance must not be powered through

an external switching device, such as a timer, or connected to a supply

that is regularly powered or switched off by the circuit.

• Provide a disconnection device (not supplied) in the plant’s power supply grid,

with a contact opening distance permitting complete disconnection under the

conditions dictated by overvoltage category III.

• Handle the product with care during installation, taking care to avoid crushing,

denting or dropping it, or allowing contact with liquids of any kind. Keep the

product away from sources of heat and naked flames. Failure to observe the

above can damage the product, and increase the risk of danger or malfun-

ction. Should this happen, stop installation immediately and contact Customer

Service.

• The manufacturer assumes no liability for damage to property, items or per-

sons resulting from non-compliance with the assembly instructions. In such

cases the warranty for material defects is excluded.

• The weighted sound pressure level of the emission A is lower than 70 dB(A).

• Cleaning and maintenance to be carried out by the user must not be carried

out by unsupervised children.

• Before working on the system (maintenance, cleaning), always disconnect the

product from the mains power supply.

• Check the system periodically, in particular all cables, springs and supports to

detect possible imbalances, signs of wear or damage. Do not use, if repairs or

adjustments are necessary, since installation failure or an incorrectly balanced

automation may cause injury.

• The packing materials of the product must be disposed of in compliance with

local regulations.

• When operating a biased-off switch, make sure that other persons are kept

away.

• When operating the gate, keep an eye on the automated mechanism and keep

all bystanders at a safe distance until the movement has been completed.

• Do not operate the product if anyone is working nearby; disconnect its power

supply before permitting such work to be done.

• If the power cable is damaged, it must be replaced by the manufacturer or by

an appointed servicing company or similarly qualified person in order to pre-

vent any form of risk.

WARNINGS AND GENERAL PRECAUTIONS

1

Original instructions

Contents

Chapter 1 - WARNINGS AND GENERAL PRECAUTIONS

1.1 - General Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 - Warnings for installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Chapter 2 - PRODUCT DESCRIPTION AND INTENDED USE

. . . . . . . . . 2

Chapter 3 - INSTALLATION

3.1 - Preliminary installation checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3.2 - Operating limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3.2.1 - Product durability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.3 - Preliminary installation set-up work . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.4 - Preparing the column for installation of the gearmotor . . . . . . . . . . . . . 4

3.5 - Installation of gearmotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

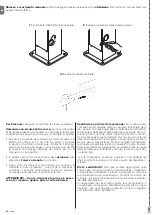

3.6 - Adjusting the mechanical limit switches . . . . . . . . . . . . . . . . . . . . . . . . 4

3.7 - Manually releasing and locking the gearmotor . . . . . . . . . . . . . . . . . . . 4

Chapter 4 - ELECTRICAL CONNECTIONS

4.1 - Description of electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Chapter 5 - FINAL CHECKS AND START UP

5.1 - Choosing the direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5.2 - Power supply connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5.3 - Recognition of the devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5.4 - Recognizing the length of the leaf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5.5 - Checking gate movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.6 - Connection of Other Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter 6 - TESTING AND COMMISSIONING

6.1 - Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6.2 - Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

MAINTENANCE OF THE PRODUCT

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

PRODUCT DISPOSAL

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 7 - PROGRAMMING

7.1 - Preset functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

7.2 - Programming keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

7.3 - Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

7.4 - Level 1 programming (ON-OFF functions) . . . . . . . . . . . . . . . . . . . . . . . 8

7.5 - Level 2 programming (adjustable parameters) . . . . . . . . . . . . . . . . . . . 8

Chapter 8 - FURTHER DETAILS

8.1 - Adding or removing devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

8.1.1 - BlueBUS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

8.1.2 - STOP input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

8.1.3 - Photocells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

8.1.4 - FT210B Photo-sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

8.1.5 - NAKED in “Slave” mod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

8.1.6 - Recognition of Other Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

8.1.7 - Radio receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

8.1.8 - Connection and installation of the buffer battery . . . . . . . . . . . . . . 12

8.1.9 - Connecting up the KA1 external release system (fig. 19) . . . . . . . 12

8.1.10 - Connecting up the Oview programmer . . . . . . . . . . . . . . . . . . . . 12

8.1.11 - Connecting the Solemyo solar energy system . . . . . . . . . . . . . . 12

8.2 - Special functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8.2.1 - Funzione “Apri sempre” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8.2.2 - Funzione “Muovi comunque” . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8.2.3 - Avviso di manutenzione . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8.2.4 - Control of the number of manoeuvres performed . . . . . . . . . . . . 13

8.2.5 - Manoeuvre counter reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 9 - TROUBLESHOOTING... (troubleshooting guide)

. . . . . . . . . .14

9.1 - Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

9.2 - Malfunctions archive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

9.3 - Flashing light signalling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

9.4 - Signals on the control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

TECHNICAL CHARACTERISTICS OF THE PRODUCT

. . . . . . . . . . . . . . 17

Declaration of Conformity

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Operation manual

(removable appendix) . . . . . . . . . . . . . . . . . . . . . . . . . . 19

PICTURES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I - VII

Summary of Contents for Naked Sliding NKSL400

Page 2: ......

Page 43: ...I 405 mm 131 mm 135 mm 1 3 4 5 b d c c h l b f m g i n e a E C F D C F A B 2...

Page 44: ...II b a b a c 5 mm 6 7 10 11 8 9...

Page 46: ...IV 14 15...

Page 48: ...VI 19 20 a b c d e...

Page 49: ...VII 21 22...

Page 50: ......

Page 51: ......