English –

15

English

06.

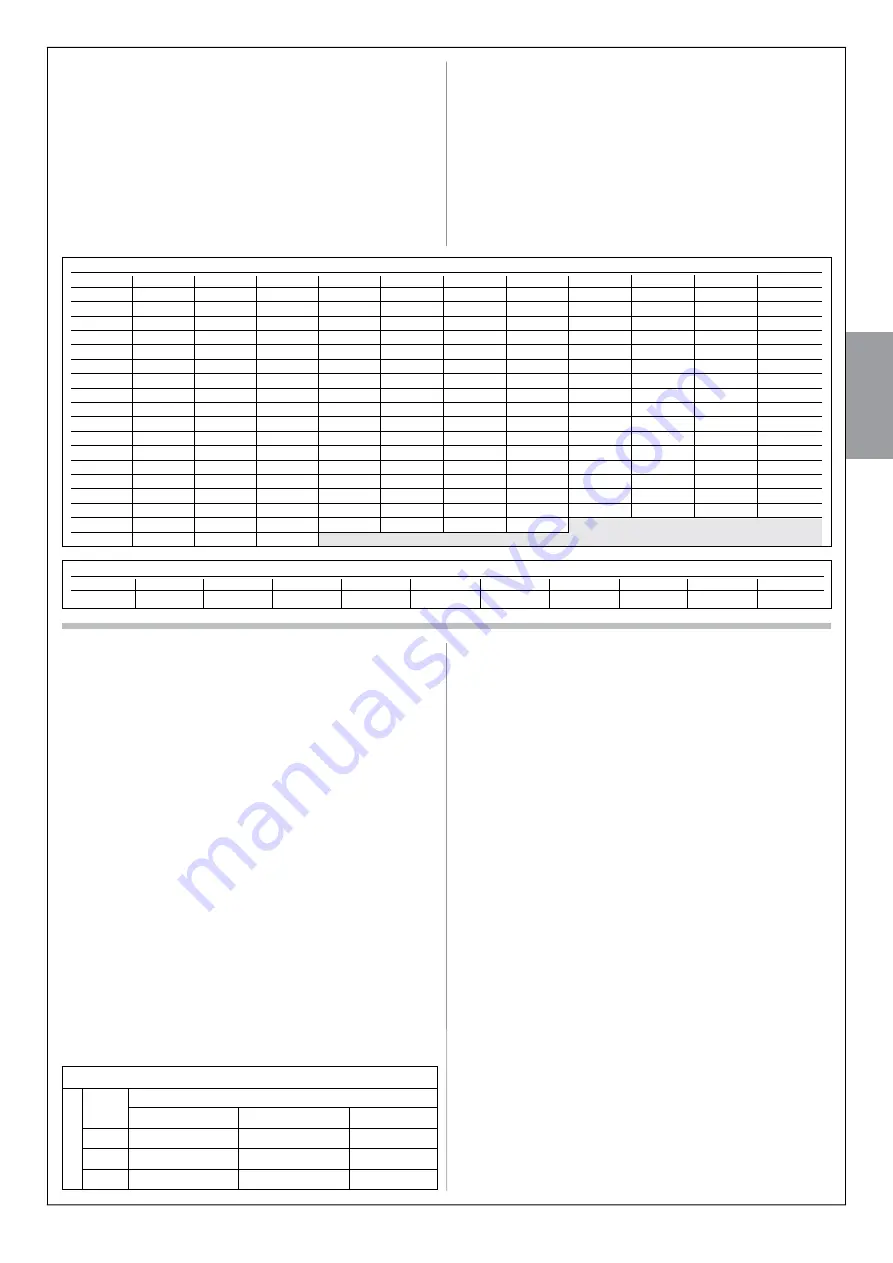

In

table A

below, select the box corresponding to the intersection of

the row with the value of Ed and the column with the value of K. The

box contains the maximum possible number of cycles per day (e.g.

Ed= 2800 and K= 105; daily cycles ≈ 22).

If the number obtained is too low for the intended use or is located in the

“area not recommended for use”, 2 or more photovoltaic panels may be

considered, or use of a photovoltaic panel with a higher power. Contact

the Nice technical assistance service for further information.

The method described, allows you to calculate the maximum possible num-

ber of cycles

per day

that the automation is capable of carrying out, accord-

ing to the solar energy supplied. The calculated value is considered an aver-

age value and the same for all days of the week. Considering the presence

of the battery, which acts as an energy “accumulator”, and the fact that the

battery also provides automation autonomy for long spells of bad weather

(when the photovoltaic panel produces very little energy) it may be possible to

exceed the calculated maximum possible number of cycles per day, provided

that the average of 10-15 days remains within the envisaged limits.

Table B

below shows the maximum possible number of cycles, accord-

ing to the

severity index

(K) of the manoeuvre, using

the stored solar

energy

of the accumulator. It is considered that initially the battery is

completely charged (e.g. after a prolonged period of good weather or

recharging via the optional PCB power supply unit) and that the manoeu-

vres are performed within a period of 30 days.

When the battery runs out of the stored energy, the led starts to indicate

the battery low signal by flashing briefly every 5 seconds, accompanied

by a “beep”.

TABLE A - Maximum possible number of cycles per day

Ed

K≤75

K=100

K=125

K=150

K=175 K=200

K=225

K=250

K=275

K=300

K≥325

9500

123

92

74

61

53 46

41

37

33

31

28

9000

116

87

70

58

50 44

39

35

32

29

27

8500

109

82

66

55

47 41

36

33

30

27

25

8000

103

77

62

51

44 39

34

31

28

26

24

7500

96

72

58

48

41 36

32

29

26

24

22

7000

89

67

54

45

38 34

30

27

24

22

21

6500

83

62

50

41

35 31

28

25

23

21

19

6000

76

57

46

38

33 29

25

23

21

19

18

5500

69

52

42

35

30 26

23

21

19

17

16

5000

63

47

38

31

27 24

21

19

17

16

14

4500

56

42

34

28

24 21

19

17

15

14

13

4000

49

37

30

25

21 19

16

15

13

12

11

3500

43

32

26

21

18 16

14

13

12

11

10

3000

36

27

22

18

15 14

12

11

10

9

8

2500

29

22

18

15

13 11

10

9

8

7

7

2000

23

17

14

11

10 9

8

7

6

6

5

1500

16

12

10

8

7 6

5

1000

9 7 6

TABLE B - Maximum number of cycles using exclusively battery power

K≤75

K=100

K=125

K=150

K=175

K=200

K=225

K=250

K=275

K=300

K≥325

741

556

445

371

318

278

247

222

202

185

171

Area of use not recommended

9.3 - ADDING OR REMOVING DEVICES

Devices can be added to or removed at any time.

Warning! – Do not add devices before you have checked that they

are fully compatible with the control unit and the motor it controls;

for details please refer to the NICE Support Service.

9.3.1 - ECSbus

ECSbus is a system that enables connections of ECSbus devices using

just two wires, which convey both electrical power and communication

signals. All devices are connected in parallel on the same 2 wires of the

ECSbus; each device is recognised individually as it is assigned a unique

address during installation.

Photocells and other devices using this system can be connected to

ECSbus, such as safety devices, control buttons, indicator lights etc. For

information about ECSbus devices, see the Nice Home product cata-

logue or visit www.niceforyou.com.

A special learning phase enables the control unit to recognise all con-

nected devices individually, and enables precise diagnostics procedures.

For this reason, each time a device connected to ECSbus is added or

removed, the learning phase must be performed on the control unit; see

paragraph 10.3.3 “Learning other devices”.

9.3.2 - STOP Input

STOP is the input that causes immediate shutdown of the movement (fol-

lowed by a brief inversion of the manoeuvre). Devices with output featur-

ing normally open “NO” contacts, and devices with normally closed “NC”

contacts, as well as devices with 8.2k

Ω

constant resistance output, like

sensitive edges, can be connected to this input.

Multiple devices, even of different types, can be connected to the STOP

input if suitable arrangements are made; see

Table 7

.

TABLE 7

2

nd

device type:

1

st

device type:

NO

NC

8,2K

Ω

NO

In parallel (

note 2

)

(

note 1

)

In parallel

NC

(

note 1

)

In series (

note 3

)

In series

8,2K

Ω

In parallel

In series

(

note 4

)

Note 1.

NO and NC combinations are possible by placing the 2 con-

tacts in parallel, taking care to place a 8.2 k

Ω

resistance in parallel to

the NC contact (thus enabling the combination of 3 devices: NO, NC

and 8.2k

Ω

).

Note 2.

Any number of NO devices can be connected to each other in

parallel.

Note 3.

Any number of NC devices can be connected to each other in

series.

Note 4.

Only two devices with 8.2k

Ω

constant resistance output can be

connected in parallel; if needed, multiple devices must be connected in

“cascade” configuration with a single 8.2 k

Ω

terminal resistance.

Warning! – If the STOP input is used to connect devices with safety

functions, only the devices with 8.2K

Ω

constant resistance output

guarantee safety category 3.

As with the ECSbus, the control unit recognises the type of device con-

nected to the STOP input during the learning phase; subsequently the

control unit gives a STOP command when it detects a variation with

respect to the learned state.

9.3.3 - Recognition of other devices

The learning operation of the devices connected to the ECSbus and

STOP input is usually carried out during the installation phase; if devices

are added or removed the learning operation can be carried out again as

follows:

01.

Press the

P2

button

[B]

(

fig. 21

) on the control unit for at least three

seconds, then release the button.

02.

Wait a few seconds for the control unit to complete the device learn-

ing phase.

03.

When the recognition procedure is complete, the

P2

led

[A]

(

fig. 21

)

will go off. If the

led

P2

flashes it means there is an error; see para-

graph 10.5 “Troubleshooting”.

04.

After having added or removed a device the automation test must be

carried out again as specified in paragraph 7.1 “Testing”.

Summary of Contents for CLB207

Page 2: ...Fran ais...

Page 9: ...Fran ais 7 Fran ais 8 7 1 Led SAFE 3 2 4 5 mm 01 03 05 02 04 9...

Page 10: ...8 Fran ais Fran ais 6 mm x4 05 B 6 mm x4 05 A 2 1 aerial flash 2 1 06 07 08 09 02 03 04 01 10...

Page 26: ...Fran ais...

Page 33: ...English 7 English 8 7 1 Led SAFE 3 2 4 5 mm 01 03 05 02 04 9...

Page 34: ...8 English English 6 mm x4 05 B 6 mm x4 05 A 2 1 aerial flash 2 1 06 07 08 09 02 03 04 01 10...

Page 50: ......

Page 57: ...Italiano 7 Italiano 8 7 1 Led SAFE 3 2 4 5 mm 01 03 05 02 04 9...

Page 58: ...8 Italiano Italiano 6 mm x4 05 B 6 mm x4 05 A 2 1 aerial flash 2 1 06 07 08 09 02 03 04 01 10...

Page 74: ...Fran ais...

Page 81: ...Polski 7 Polski 8 7 1 Led SAFE 3 2 4 5 mm 01 03 05 02 04 9...

Page 82: ...8 Polski Polski 6 mm x4 05 B 6 mm x4 05 A 2 1 aerial flash 2 1 06 07 08 09 02 03 04 01 10...