26

EXTERNAL ENTRAPMENT PROTECTION

Non-contact and contact sensors must be installed individually or in

combination with each other to provide external entrapment protection.

Care should be exercised to reduce the risk of nuisance tripping, such as when

a vehicle trips the sensor while the gate is still moving, and one or more non-

contact sensors shall be located where the risk of entrapment or obstruction

exists, such as the perimeter reachable by a moving gate or barrier.

A hardwired contact sensor shall be located and its wiring arranged so

that the communication between the sensor and the gate operator is not

subjected to mechanical damage.

A wireless contact sensor such as one that transmits radio frequency (RF)

signals to the gate operator for entrapment protection functions shall be

located where the transmission of the signals are not obstructed or impeded

by building structures, natural landscaping or similar obstruction.

DURING INSTALLATION

• DISCONNECT POWER at the control panel before making any electric

service power connection.

• Be aware of all moving parts and avoid close proximity to any pinch points.

• Know how to operate the manual release.

• Adjust the unit to use the minimum force required to operate the gate

smoothly even during mid-travel reversing.

• Place controls a minimum of 8 feet away from the gate so that the user

can see the gate and operate controls but cannot touch the gate or gate

operator while operating the controls.

• Warning signs must be placed on each side of the gate or in high-visibility

areas to alert of automatic gate operations.

Moving Gate can cause

Serious Injury or Death.

Persons are to keep clear! The gate is able to be moved without prior warning.

Do not allow children to operate gate or play in gate area.

This entrance is for vehicles only. Pedestrians must use separate entrance.

Le portail en mouvement peut causer

des blessures graves ou la mort.

Les personnes ne devront pas s’approcher!

Le portail est capable d'être bougé sans avertissement préalable.

Ne pas laisser les enfants utiliser le portail ou jouer dans le domaine du portail.

Cette entrée est réservée aux véhicules.

Les piétons devront utiliser une entrée séparée.

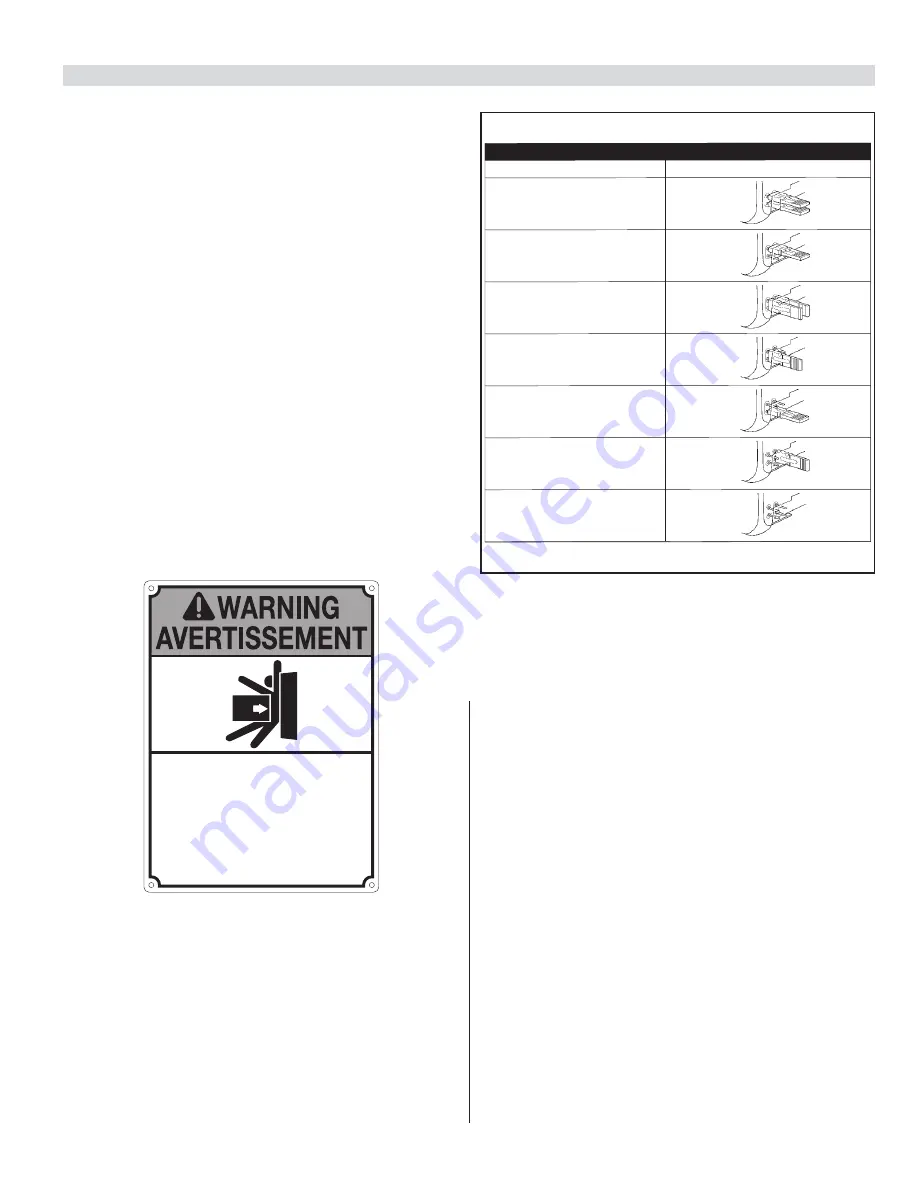

20.1 - MONITORED SAFETY DEVICE TYPES

BlueBus photo-eyes:

The EPMOB photocell is a thru-beam device - consisting of a transmitter

(TX) and a receiver (RX) that connects via two (2) wires. Polarity of the wiring

is not important. EPMOBs may be wired in parallel to one another or directly

to the board - it is not necessary to make a “home run” to the board with

each EPMOB. Multiple sets of EPMOBs may be used, however each PAIR

must be set to an exclusive address by setting the jumpers in the units.

What this means, is that each pair of eyes must have their jumpers set to

match each other - but every pair must be set differently from the other

pairs. The address jumpers also determine the functionality of each set of

eyes:Open direction or close direction, etc. (see Table 1)

20 - ACCESSORIES AND SENSORS

Photocell

CLOSE DIRECTION A

Jumpers

Table 1

CLOSE DIRECTION B

CLOSE DIRECTION 2A

CLOSE DIRECTION 2B

OPEN DIRECTION A

OPEN DIRECTION B

NOT USED

1

.

Mount the transmitter and receiver appropriately to a rigid mounting

surface. Eyes should be placed appropriately to protect areas of

entrapment according to UL325 guidelines.

2

.

Set the jumpers in each pair of eyes to match each other. Ensure that

each pair of eyes are set differently. Use the table below to find the

setting of the jumpers that corresponds to the functionality desired from

each pair of eyes.

3

.

Connect the EPMOBs to the Bluebus connector of the circuit board.

Polarity of the wiring is not important. Eyes may be connected in

parallel to one another - or directly to the board.

4. LEARN the Bluebus port.

On a 1050 board - Press Functions (1. Learn) - Press “OK” (Learn

Bluebus) - Press “OK”. Allow the board to scan the Bluebus Port.

When complete - test the functionality of each set of eyes.

5. Fine tune the alignment of each pair of eyes. The more slowly the lights

flash on the units - the better they are aligned.

Close Direction A/B:

Resets timer to close in open position, reverses

gate if closing, no effect if gate is closed or during opening cycling. Typically

used when the photo eyes are on the outside of the property (gates opening

inward.

Close Direction 2 A/B:

Resets timer to close in open position,

reverses gate if closing AFTER obstruction is cleared, pauses the gate on

opening cycle - opening resumes after obstruction clears. Typically used

when the photo eyes are on the inside of the property (gates opening

inward).

Open Direction A/B:

Delays gate opening from closed position.

Stops and reverses gate back closed on open cycle. Typically used to

protect an entrapment point when the gates are opening.

Summary of Contents for Apollo 4300SW

Page 2: ......

Page 40: ...38 35 GATE ARM INSTALLATION Figure 33 CORRECT LAYOUT INCORRECT INSTALLATION Figure 34...

Page 44: ......

Page 45: ......