- 1.9 -

Names and function of the parts under the front cover

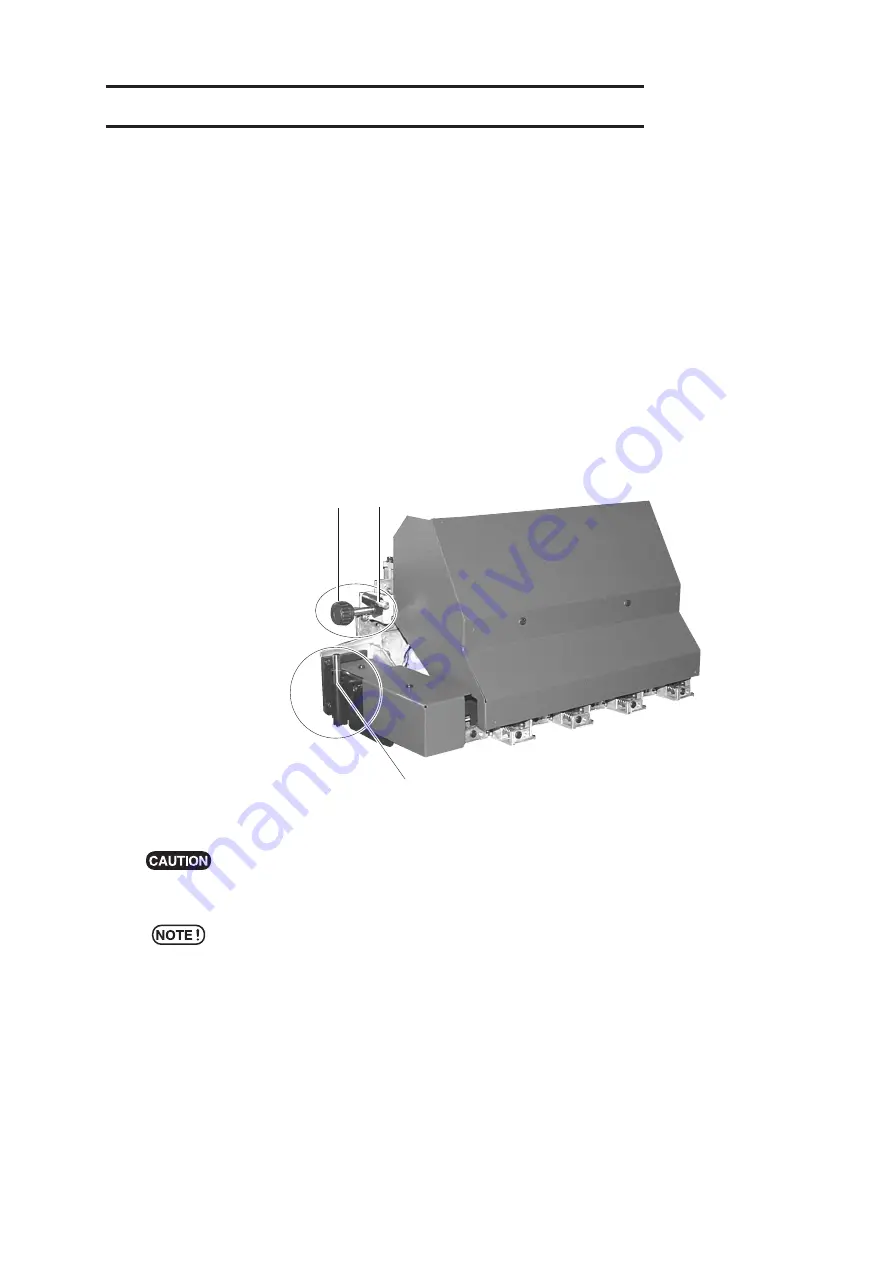

Under the front cover, there are the carriage, capping station, etc. necessary for printing

operation. The mechanisms provided under the front cover are explained below.

Carriage

The carriage is provided with print heads for plotting, etc. It is also provided with a head height

adjustment screw for adjusting the head height according to the thickness of the fabric used.

The carriage moves during plotting, and fabric detection.

When cleaning the capping station, execute the STATION MAINTENANCE function to move

the carriage. (See page 4.8 “Moving the carriage for cleaning the station interior [Carriage

Out].”)

• Starting the plotting operation without adjusting the carriage height can cause

damage not only to the fabric but also to the plotter itself.

• When setting a fabric in position for plotting, be sure to adjust the head

height.(See page 1.30)

Support screw

Height adjustment screw

Head height adjustment rod

Summary of Contents for DS-1600

Page 2: ......

Page 110: ......

Page 146: ...4 36...

Page 171: ......

Page 172: ...Printed in Japan D201421 MIMAKI ENGINEERING CO LTD 2006 NH...