- 3.14 -

Ink discharge way cleaning [Drain Wash]

The ink discharge way may become clogged by coagulated ink. It must be cleaned at regular inter-

vals to avoid clogging.

Ink discharge way: Tubing between the cap and the waste ink tank

• When cleaning the machine, be sure to wear the goggle and gloves to

prevent from getting ink in your eyes or on hands.

• Do not move the carriage out of the capping station by hand.

Use the appropriate operation key to move the carriage.

Cleaning Tools :

• Cleaning liquid for maintenance

• Goggle, Gloves

• Pipette

STEPS:

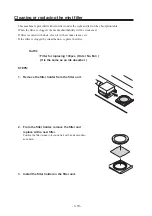

1.

Press the [FUNCTION] key once.

2.

Press the XY [ ] or [ ] keys to select [MAINTE-

NANCE].

3.

Press the [ENTER] key.

[Station] is displayed.

4.

Press the [ENTER] key.

[Carriage out] is displayed.

5.

Press the XY [ ] or [ ] keys to select [Drain

Wash].

6.

Press the [ENTER] key.

The table moves backward, the Y-bar moves to the top, the

wiper moves forward, and the carriage moves on the table.

Dry suction starts in cycles consisting of 10 seconds of

suction followed by 10 seconds of pause.

FUNCTION

MAINTENANCE

< ENT >

MAINTENANCE

Station

< ent >

Station Maint

Sel

: Carriage Out

Station Maint

Sel

: Drain Wash

Drain Wash

Completed

: ent

FUNCTION

SETUP

< ENT >

Summary of Contents for DM3-1810S

Page 2: ......

Page 20: ... xvi ...

Page 34: ... 1 14 ...

Page 76: ... 3 20 ...

Page 112: ... 6 10 ...

Page 131: ... A 19 TYPE Refresh Level3 TYPE mm inch mm X Level0 Level3 X inch Function flowchart ...

Page 141: ... A 29 MAIN Ver1 00 I F Ver Function flowchart ...

Page 144: ...D201258 1 10 30032007 ...

Page 145: ......

Page 146: ...PrintedinJapan MIMAKI ENGINEERING Co Ltd FW 5 10 NH ...