MS-890 Industrial Automation Scanner

User Manual

12-5

Utilities

Enable Extended Read Rate Test for Single and Multisymbol

Sending

<Ce>

after

<C>

or

<Cs>

will generate a an extended mode that applies to both

single and multiple symbols.

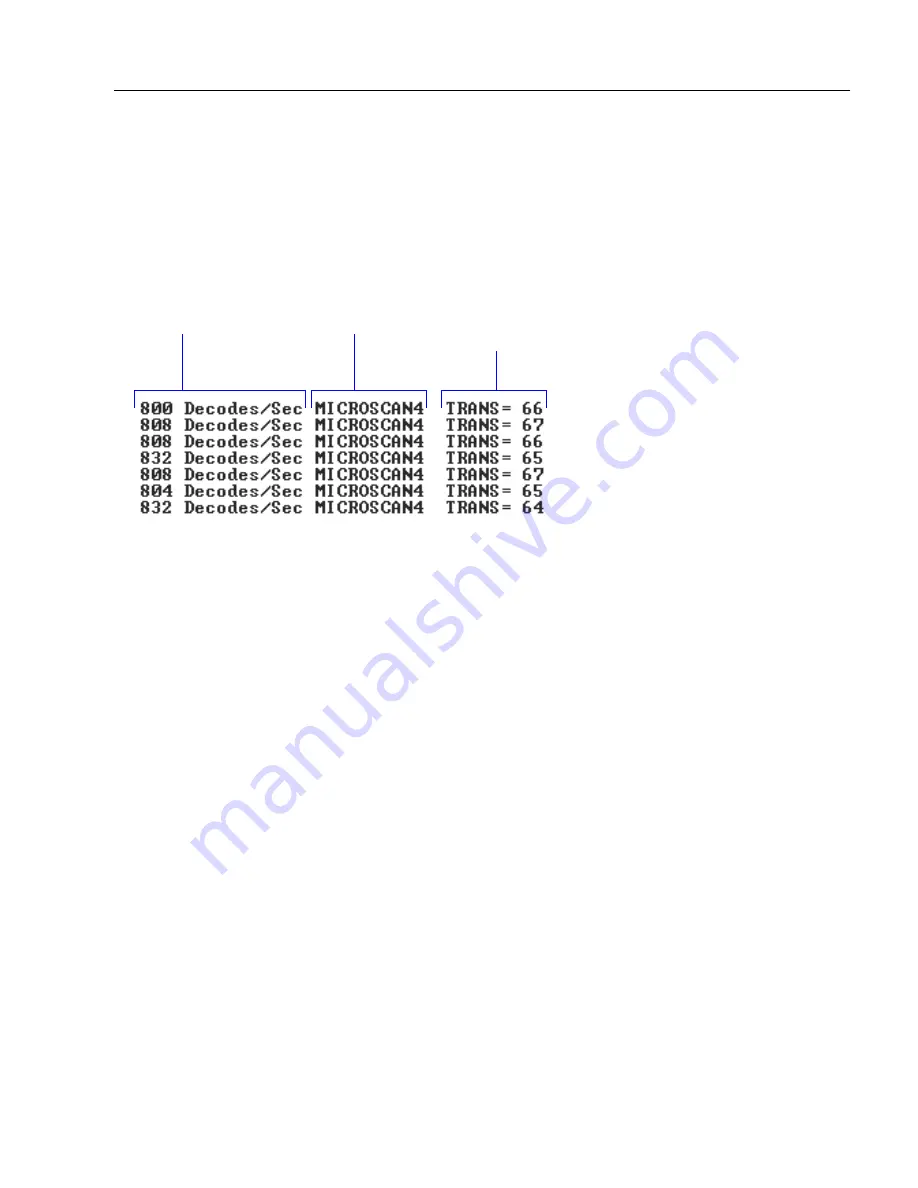

Extended Mode instructs the scanner to output the decode rate, the symbol data, and the

transition data.

The example below shows output with Postamble enabled and defined as Carriage

Return/Line Feed.

Note:

The

<Ce>

command has no immediate effect if not preceded by

<C>

or

<Cs>

.

End Read Rate Test

Sending

<J>

ends both the

Percent

test and the

Decodes/Second

test for both single

and multisymbol.

Decode rate

Symbol data

Number of bar/space

transitions

Summary of Contents for MS-890

Page 1: ...MS 890 Industrial Automation Scanner User Manual P N 84 000890 Rev B...

Page 12: ...xii MS 890 Industrial Automation Scanner User Manual Statement of RoHS Compliance...

Page 26: ...1 14 MS 890 Industrial Automation Scanner User Manual Save Configuration in ESP...

Page 44: ...2 18 MS 890 Industrial Automation Scanner User Manual Send Receive Options...

Page 94: ...4 24 MS 890 Industrial Automation Scanner User Manual Tracking Adjustment...

Page 122: ...5 28 MS 890 Industrial Automation Scanner User Manual Autodiscriminate...

Page 154: ...6 32 MS 890 Industrial Automation Scanner User Manual Quality Output...

Page 168: ...7 14 MS 890 Industrial Automation Scanner User Manual Mismatch Replace...

Page 202: ...9 22 MS 890 Industrial Automation Scanner User Manual Calibration by Embedded Menu...

Page 212: ...10 10 MS 890 Industrial Automation Scanner User Manual Raster Laser by Embedded Menu...

Page 240: ...12 22 MS 890 Industrial Automation Scanner User Manual Scanner Status Requests...

Page 264: ...14 10 MS 890 Industrial Automation Scanner User Manual Mounting Plate...

Page 308: ...A 44 MS 890 Industrial Automation Scanner User Manual Glossary of Terms...