M

‑

I SWACO

MONGOOSE PRO Shale Shaker

35

Field Installation and Operation Manual 9092F02001AENG (D)

35

15.4

Maintaining Motors

NOTE

INSTALLATION OF VIBRATORY MOTOR SHOULD BE COMPLETED BY A CERTIFIED

ELECTRICIAN.

15.4.1

Lubricating Motor Bearings

Operators must lubricate Motor Bearings every 2000 Operational Hours to maintain optimum performance and

reliability.

TIP

ONLY USE KLUBER ISOFLEX TOPAS NB52 LUBRICANT TO OIL THE BEARINGS.

FAILURE TO DO SO WILL VOID THE MOTOR MANUFACTURER WARRANTY.

4.

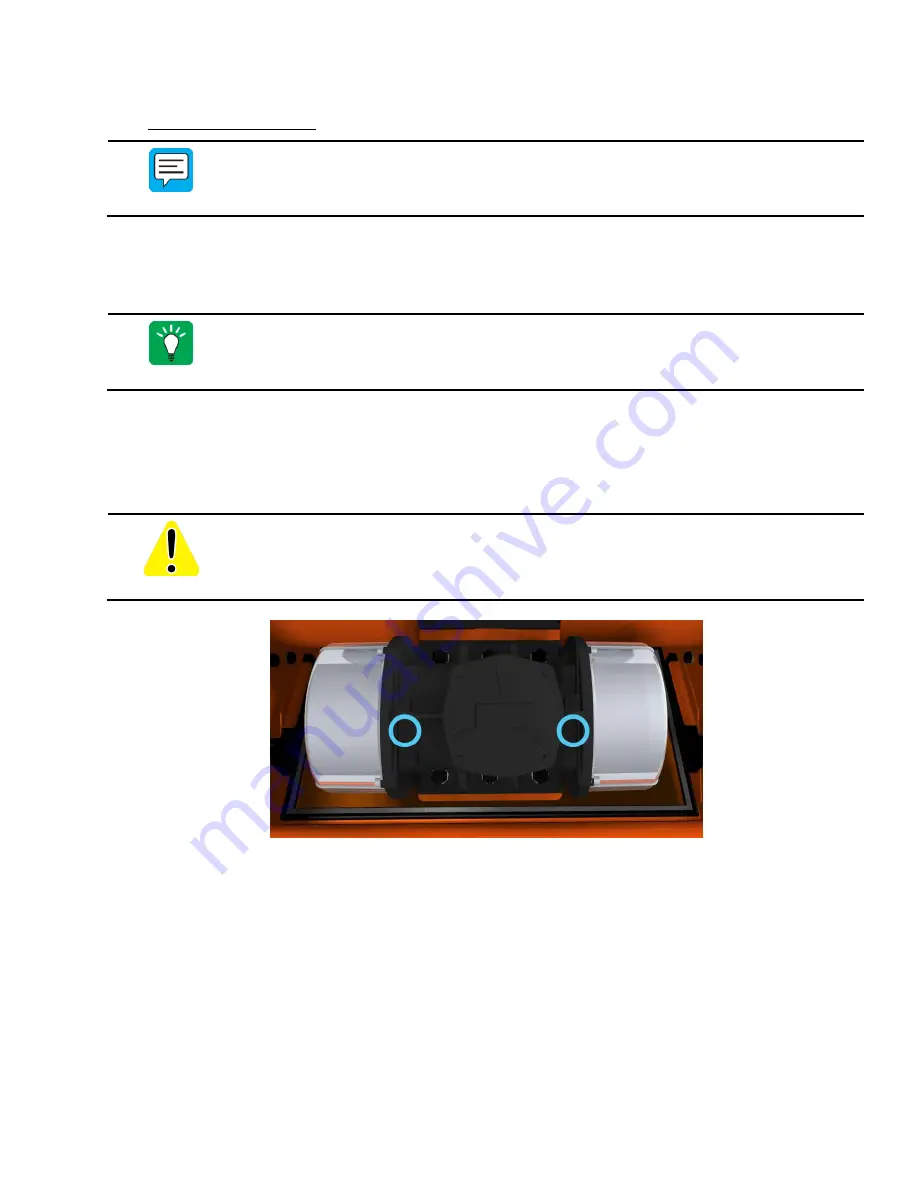

Remove plugs, one for each bearing (Refer to Figure 29).

5.

Insert a 1/8” NPT Zerk grease fitting.

6.

Pump 1.41 ounces (40 g) of lubricant into each bearing for normal bearing surface temperatures below

195°F (91°C).

CAUTION

DO NOT OVERFILL GREASE FITTINGS. ADDING TOO MUCH GREASE WILL CAUSE

OVERHEATING AND DESTROY THE MOTOR.

Figure 29. Grease Fittings (Circled)