M

‑

I SWACO

MONGOOSE PRO Shale Shaker

3

Field Installation and Operation Manual 9092F02001AENG (D)

3

5.

EQUIPMENT FUNCTION

The MONGOOSE PRO Shale Shaker has a screen deck made of four pretensioned composite wire mesh screens.

Each Shale Shaker screen is secured to the basket with two screen wedges. An optional stainless steel vibratory

vent hood upgrade is available for jobs that require fume extraction. The Shale Shaker deck adjustment system

allows flexible control of fluid pool depth and beach length in a variety of drilling conditions.

The Shale Shaker is equipped with two explosion-proof vibratory motors that produce a dual motion system. The

normal mode is a progressive elliptical motion used during normal drilling conditions to maximize both cuttings

retention time and screen life. The motor output for this mode is 6.5Gs. The capacity mode is used during fluid

surges and heavy solids loading. The motor output is 7.5Gs when operating in capacity mode.

5.1

Identification of Main Components

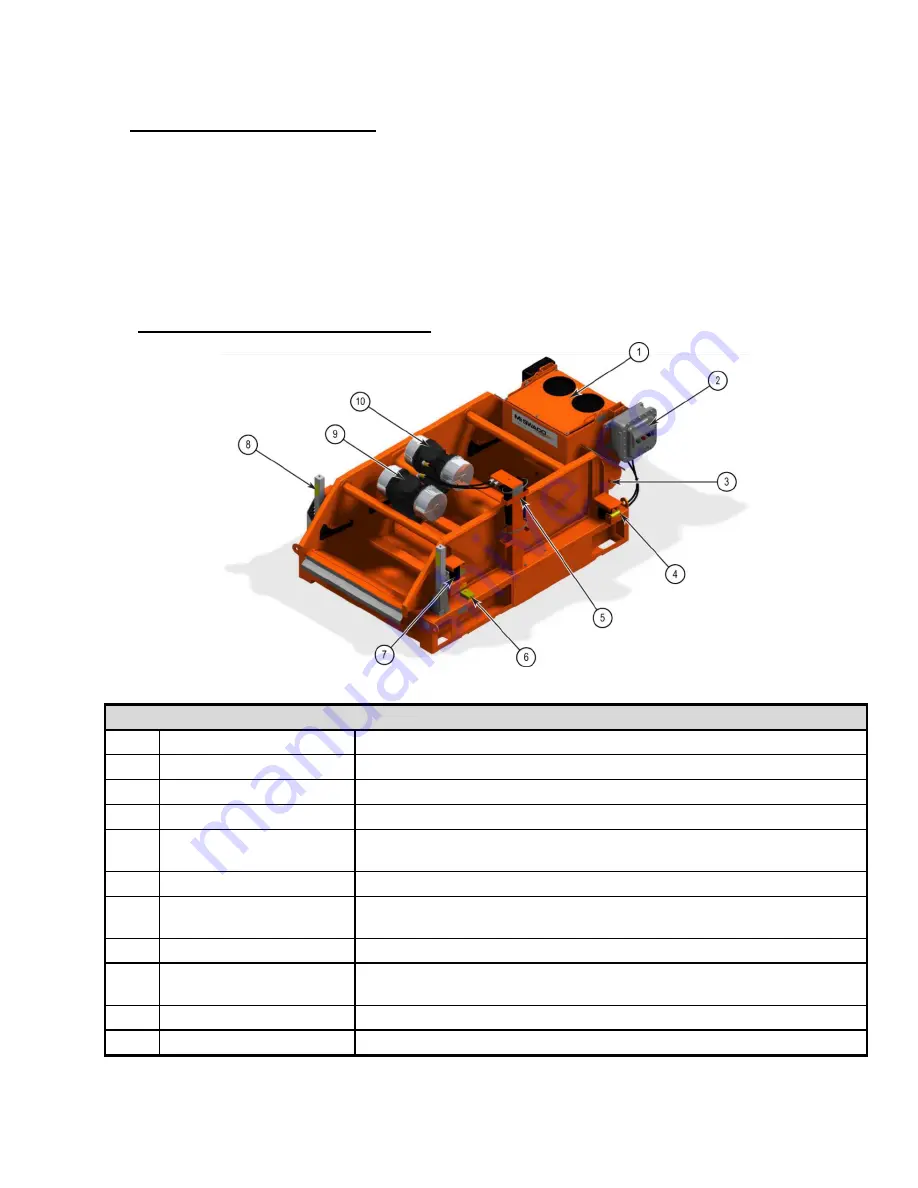

Figure 1. Main Components, MONGOOSE PRO Shale Shaker [Typical]

FIGURE 1 LEGEND

ITEM

NAME

DESCRIPTION

1

HEADER BOX

ROUTES FLUID TO SHAKER SCREENS

2

CONTROL PANEL

HOUSES CONTROLS FOR THE ELECTRICAL COMPONENTS

3

BASKET

HOLDS THE MOTORS AND WIRE MESH SCREENS

4

FEED END SHIPPING

BRACKET

SECURES THE FEED END OF THE SHAKER DURING

TRANSPORTATION

5

CABLE TOWER

ROUTES MOTOR CABLES AND HOLDS SCREEN WEDGES

6

DISCHARGE END

SHIPPING BRACKET

SECURES THE DISCHARGE END OF THE SHAKER DURING

TRANSPORTATION

7

BASKET SPRING

ISOLATES VIBRATORY MOTION ON THE BASKET FROM THE SKID

8

DECK ADJUSTMENT

ELEVATOR JACK

RAISES OR LOWERS THE DECK ANGLE TO OPTIMIZE FLUID AND

SOLIDS FLOW DURING OPERATION

9

SWING WEIGHT MOTOR PROVIDES ADJUSTABLE VIBRATORY MOTION TO EQUIPMENT

10

FIXED WEIGHT MOTOR PROVIDES VIBRATORY MOTION TO EQUIPMENT