SECTION 2 - GENERAL INSTALLATION INFORMATION

2-40

MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL

indoors. Remove all clamping cylinders

from the clamp ring and fill each cylinder

with Mobilarma 522 or equivalent. Drain

each cylinder and plug port with a metal

SAE O-ring plug. Coat all unpainted

surfaces with CRC Industries SP 400

(corrosion inhibitor) or equivalent. Place

cylinders in a crate with plug facing up and

store indoors. Remove the clamp ring and

coat any unpainted surfaces on the

adjustment ring and clamp ring with CRC

Industries SP 400 (corrosion inhibitor) or

equivalent. Reinstall clamp ring without

clamping cylinders. Cover the threads of the

adjustment ring and clamp ring with a

liberal amount of lithium based grease NLGI

No. 1 containing a minimum of 3%

molybdenum disulfide. Remove the

adjustment cap seal and place in a heat

sealed plastic bag along with an

appropriately sized bag of desiccant.

Desiccant can be purchased in various sizes

based on the volume of the packaged area,

the length of storage time and the conditions

in which the package is stored. Desiccant

bags are available from most packaging and

shipping companies.

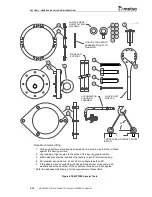

4. Tramp Release Cylinder Assemblies —

Remove the nut and cone and coat parts with

CRC Industries SP 400 (corrosion inhibitor)

or equivalent. Check the precharge on the

accumulator to insure it is between 5 and

15 psi. Remove the mounting bracket from

the bottom of the cylinder and place the

cylinder on its side with the boss facing

upward. Remove the O-ring plug from the

port just above the accumulator and fill the

cylinder with Mobilarma 522 or equivalent.

Do not remove the plugs from the two side

ports. Filling the cylinder this way will

allow oil to enter the accumulator. When the

cylinder and accumulator are full install an

SAE O-ring plug in the port. Approximate

volume of oil required per cylinder and

accumulator is 15 liters (4 gallons). Coat the

unpainted surfaces on the outside of the

cylinder assembly with CRC Industries

SP 400 (corrosion inhibitor) or equivalent.

Replace the mounting bracket and place the

assembly in a crate on its side with the

accumulator facing up. Store the crate

indoors.

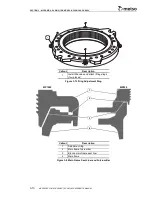

5. Eccentric Assembly — Remove the

counterweight and gear from the eccentric

assembly. Coat all surfaces with CRC

Industries SP 400 (corrosion inhibitor) or

equivalent. Because these parts are in the

normal flow path of the lubricating oil when

the Crusher is running, it is recommended

that these parts be stored indoors or are

covered by a tarpaulin if stored outdoors.

6. Head Assembly — Apply a coating of at

least 4 mils (0.10 mm [0.004 inches])

(2 coats) of CRC Industries SP 400

(corrosion inhibitor) or equivalent to the

head ball, the bore of the upper and lower

head bushings, machined surfaces of the

head above the head ball (if the Crusher uses

a clutch style antispin device some

additional disassembly may be required) and

all areas of the head adjacent to the T-seal.

7. Bowl and Hopper Assembly — Remove the

hopper and adjustment cap from the bowl to

expose the wedges and hardware used for

mounting the bowl liner. Coat all hardware

and unpainted surfaces with CRC Industries

SP 400 (corrosion inhibitor) or equivalent.

There is no need to coat the surfaces of the

bowl liner. Clean the threads of the bowl and

recoat with CRC Industries SP 400

(corrosion inhibitor) or equivalent. Cover

the threads of the bowl with a liberal amount

of lithium based grease NLGI No. 1

containing a minimum of 3% molybdenum

disulfide. Apply a coating of Mobilarma 522

or equivalent to the fasteners and remount

the adjustment cap to the bowl. The

assembly can now be stored outside exposed

to the elements. To reduce corrosion due to

exposure the bowl and hopper assembly can

be covered with a sheet of 8 mil.

black

polyethylene to prevent water from seeping

into the Crusher. The covering must be

supported with bracing and positioned to

shed any water away from the component.

8. Hydraulic Power Unit — Remove the fill

plug from the top of the reservoir and drain

any existing oil from the tank. Remove the

top of the filter inside the cabinet. Start

filling the filter housing with Mobilarma

Summary of Contents for MP1000

Page 1: ...Nordberg MP Series Cone Crusher ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 8: ......

Page 64: ...SECTION 0 SAFETY 0 56 MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL ...

Page 66: ......

Page 74: ......

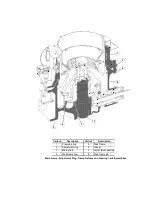

Page 154: ...Countershaft and Countershaft Box Callout Description 1 Countershaft 2 Countershaft box 1 2 ...