SECTION 3 - M. FRAME, ADJ. RING, TRAMP REL. & CLRNG JACK ASSY

3-6

MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL

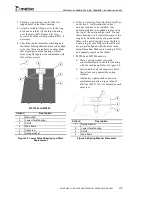

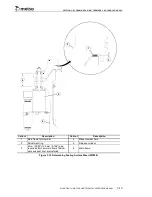

3.3.4 Seal Replacement

The U-shaped seal installed around the gear well

portion of the main frame is normally not subjected

to contact or wear. However, if the seal is damaged

in any way, it is important that it be replaced. The

seal prevents oil leakage and protects the precision

machined surfaces of the gear, pinion, and bearings

from harmful dust infiltration. Replace the seal as

follows (refer to Figure 3-5):

1. Remove the damaged seal and completely

clean out any adhesive that remains in the

seal groove. Use a sharpened chisel or stiff

putty knife to cut through the seal and scrape

the old adhesive out of the groove.

2. Thoroughly clean the groove with an oil free

solvent and allow to dry. Use alcohol or

acetone.

3. The new seal is molded and comes in four

segments, thoroughly clean the bottom and

up each side surface 10 – 15 mm

(0.39 – 0.59") of the seal using coarse sand

paper to remove the surface shine before

cementing the seal in place.

These seals were coated with a mold release

agent which allows the seal to be removed

from their mold during manufacture. In

order for the seal to adhere properly to the

adhesive used to hold the seal in the groove

in the frame, this release agent must be

completely removed.

4. Before gluing the segments into the frame,

first place three of the segments in the

groove as the fourth segment will have to be

trimmed on one end to fit into the remaining

space. Make sure the end of the segment is

cut square to the end of the adjacent segment

to insure a strong bond when gluing the

segments into the frame.

Figure 3-5 Installing Frame U-Seal

5. Apply

activator

in a very thin film to

bottom of seal

. If an excessive amount of

activator is applied, a partially cured bond

may result.

6. Sparingly apply

adhesive to bottom of

groove

. Apply only enough adhesive to

ensure minimal squeeze out.

7. Position the seal into the groove as soon as

possible after adhesive application. Maintain

enough force on the bottom of the seal so

that there is pressure contact between the

seal and the bottom of the groove. A

handling bond is attained in approximately

three minutes.

WARNING

Provide adequate ventilation when using

chemicals and glue when replacing the seal

to prevent inhalation of fumes.

NOTICE

If the mold release agent is not completely

removed, the seal could come loose during

operation.

Callout

Description

1

Apply activator to bottom and sides of

U-seal

2

U-seal

3

Apply adhesive to sides and bottom of

frame seal groove

4

Frame seal groove

5

Main frame

NOTICE

Make sure to also clean the ends of the

segments, then coat one end with activator

and the other end with adhesive.

1

3

5

4

2

Summary of Contents for MP1000

Page 1: ...Nordberg MP Series Cone Crusher ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 8: ......

Page 64: ...SECTION 0 SAFETY 0 56 MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL ...

Page 66: ......

Page 74: ......

Page 154: ...Countershaft and Countershaft Box Callout Description 1 Countershaft 2 Countershaft box 1 2 ...