SECTION 2 - GENERAL INSTALLATION INFORMATION

MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL

2-13

The narrower belts are designed for compactness of

drive, drive economy and reduced overhung load.

Banded belts are single belts unitized with a

common cover to prevent belt whip or turnover.

Banded belts fit all standard sheaves, however,

banded belts should be limited to only 2 or 4

individual belts banded together.

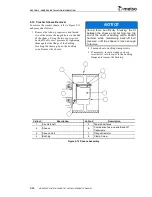

If the motor sheave is to be located directly

ABOVE the countershaft or within 30° of the

crusher vertical centerline, the factory must be

informed as to the position of the drive sheave, so

that the OUTER countershaft bushing can be

properly installed.

The Crusher may also be direct driven, that is,

coupling connected to a driving motor.

Any problems related to the crusher drive should be

submitted to the factory for suggestions.

2.7 Crusher Motor

The recommended electrical driving motor is a

crusher duty squirrel cage induction motor;

continuous rated, with normal starting torque

(approximately 125%) and normal breakdown

torque (approximately 200%) with 10%

acceptable voltage variance. It is recommended that

crusher motors of the horsepower used with MP

Crushers be equipped with reduced voltage starters.

Abrasive resistant insulation and stator thermostats

(an internal protective device) are suggested. The

motor can either be open drip-proof or totally

enclosed fan cooled.

To maintain continuous service of the

recommended operating horsepower level shown

on the mounting and clearance drawing, an electric

motor with 1.15 service factor is required. If a

service factor of 1.0 is used, the horsepower rating

appearing on the motor’s nameplate should be

approximately 15% higher than the recommended

operating horsepower. However, the crusher power

draw is to be held to the horsepower shown on the

mounting and clearance drawing.

With the V-belt drive, slide rails under the jack

shaft drive base are required to provide allowance

for the V-belt take-up due to belt stretch and for belt

installation.

If a direct drive is used, care should be taken when

ordering the motor that the motor shaft extension

and bearings are adequately sized for a direct drive

application. The motor shaft diameter must be able

to withstand peak torque. The motor manufacturer

should contact Metso Minerals regarding the gear

mesh frequency for motor design. The motor will

also require special consideration for shock and

vibration.

All horsepower ratings referred to on mounting and

clearance drawings are based on electric

horsepower.

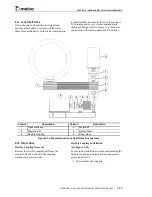

2.8 V-belt Drive

It is important that this entire section be completely

read before installing and tensioning the V-belt

drive.

2.8.1 Initial Installation of V-belt Drive

For the initial installation or when reassembling the

V-belt drive, proceed as follows:

1. Clean all oil, grease or rust from the sheave

grooves.

2. Make certain that the sheaves are correctly

aligned and that the shafts are parallel.

3. Never force belts onto sheaves. Always

shorten the center distance until belts can be

slipped on easily. To determine the

minimum allowances for shortening or

lengthening the center distance between

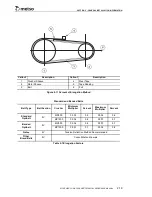

sheaves, see Table 2-5.

After calculating a center distance from a

standard pitch length make provision that

the centers can be moved closer together by

the amount shown in Figure 2-8 and

Table 2-5 to facilitate installing the belts

without injury. Also, the centers should be

adjustable over the calculated distance by an

amount as shown in the last column of

Table 2-5 because of manufacturing

tolerance and possible stretch and wear of

belt.

4. Always use a matched set of belts and use

new belts of the same manufacture. Never

mix worn and new belts.

5. Frequently check the tension on a new drive

during the first day of operation.

Summary of Contents for MP1000

Page 1: ...Nordberg MP Series Cone Crusher ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 8: ......

Page 64: ...SECTION 0 SAFETY 0 56 MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL ...

Page 66: ......

Page 74: ......

Page 154: ...Countershaft and Countershaft Box Callout Description 1 Countershaft 2 Countershaft box 1 2 ...