SECTION 3 - M. FRAME, ADJ. RING, TRAMP REL. & CLRNG JACK ASSY

MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL

3-25

20. Reinstall all hose connections to the

cylinder, bleed the air from the tramp release

circuit and pressurize the system and check

for leaks. Refer to

Bleeding the Tramp

Release Circuit

in

Section 12

for

instructions on bleeding and pressure testing

the tramp release circuit.

3.4.9 Accumulator Bladder Replacement

For accumulator bladder replacement procedure,

refer to

Accumulator Repair

in

Section 12

.

3.4.10 Main Frame Ring Replacement

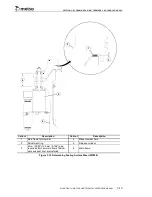

A frame ring has been installed into the main frame

at the inner countershaft box as shown in

Figure 3-18. The purpose of this ring is to eliminate

the need of having to remove the frame from the

foundation to rework the inner bore (due to

excessive bore wear). If excessive bore wear

occurs, all that need be done is to replace the frame

ring. To replace the frame ring proceed as follows:

1. Remove the following components to gain

access to the ring:

– Bowl (

Section 8

)

– Head (

Section 7

)

– Socket and Socket Liner (

Section 6

)

– Eccentric (

Section 5

)

– Countershaft Box (

Section 4

)

2. Drive the ring out of the frame bore from

inside the pinion well toward the outside.

3. Clean frame bore, inspect and measure

diameters. Convey this information to Metso

Product Support Department for possible

rework requirements.

4. Clean the new frame ring O.D. with Loctite

Safety Solvent 75559, alcohol or acetone.

5. Cool ring to at least the temperature

difference between ring and frame defined

in Figure 3-19.

6. Install ring into frame. Allow temperatures

of the Ring and Frame to normalize before

installing countershaft box into frame.

Figure 3-18 Main Frame Ring

3.4.11 Adjustment Ring Installation

The adjustment ring assembly consisting of the dust

shell, pin bushing, pin covers, clamping ring and

clamping cylinders has been shipped assembled as

one unit (refer to Figure 3-20).

To assemble the adjustment ring assembly onto the

main frame do the following:

1. Attach shackles and lifting slings to the lift

lugs, four on the MP1000, three on the

MP800, located on the outside diameter of

the adjustment ring. Refer to Figure 3-7 and

Figure 3-20.

2. Coat the Adjustment Ring seat with a

lithium base grease, NLGI No.1 containing a

minimum of 3% molybdenum disulfide.

NOTICE

Do not pump oil into the tramp release

circuit before the accumulators are

pre-charged with nitrogen. This could

damage the bladder and necessitate an

accumulator replacement.

Callout

Description

1

Main frame

2

Main frame ring

1

2

Summary of Contents for MP1000

Page 1: ...Nordberg MP Series Cone Crusher ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 8: ......

Page 64: ...SECTION 0 SAFETY 0 56 MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL ...

Page 66: ......

Page 74: ......

Page 154: ...Countershaft and Countershaft Box Callout Description 1 Countershaft 2 Countershaft box 1 2 ...