SECTION 3 - M. FRAME, ADJ. RING, TRAMP REL. & CLRNG JACK ASSY

MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL

3-19

4. Release the nitrogen pressure from the

accumulator. Refer to

Accumulator

Replacement

later in this section for the

process of safely releasing the nitrogen

pressure from the accumulator.

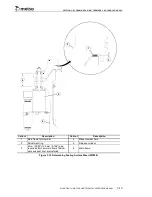

5. Thread an M20 eyebolt into the end of the

cylinder rod. The eyebolt must be turned

down completely so that the shoulder of the

eyebolt is seated on the top surface of the

cylinder rod. The M20 eyebolt used must

have a diameter not to exceed 72 mm

(2.83") in order to pass through the rod nut.

6. Lower a lifting sling from an overhead crane

through the hole in the drive ring and

connect to the eyebolt with a shackle. The

shackle and sling used to connect to the

eyebolt must have adequate capacity and a

width not to exceed 72 mm (2.83") in order

to pass through the rod nut. The lifting sling

must have adequate length to enable the

cylinder to drop to the floor or platform

before the hook on the overhead crane hits

the drive ring.

7. Take up any slack in the lifting sling. If an

overhead crane is not available, scaffolding

can be built to support a chain hoist to

remove the tramp release cylinder assembly.

8. Remove the rod nut and bearing cone from

the threaded end of the cylinder rod.

9. Slowly lower the tramp release cylinder to

the floor or platform and remove the shackle

and eyebolt from the cylinder rod.

10. Remember to remove the rod nut and

bearing cone from the sling above the

adjustment ring.

11. Refer to

Section 12

for tramp release

cylinder re-building instructions.

3.4.5 Tramp Release Cylinder and

Accumulator Installation

Due to the size and weight of the accumulator it is

necessary to remove and install the tramp release

cylinder and accumulator as an assembly.

Install a new or repaired cylinder as follows:

1. Index the drive ring so that one of the two

50 mm (1.97") diameter holes in the drive

ring is above and directly in line with the

mounting location of the tramp release

cylinder that is being installed. On more

recent Crushers, these holes have been

provided in the drive ring for handling the

tramp release cylinder, if your Crusher does

not have these holes in the drive ring contact

Metso Product Support Department for

instructions on how and where to add the

holes.

2. Lock out and tag all electrical power

supplied to the power unit and Crusher and

depressurize the clamping and tramp release

circuits by opening the clamping cylinder

and tramp release cylinder needle valves

located on the side of the hydraulic power

unit at the hose connection area. Verify that

the pressure gauges (PI-1 for the clamping

cylinder circuit and PI-2 for the tramp

release circuit) read zero pressure.

3. With the tramp release cylinder on the floor

or platform directly below its mounting

location on the adjustment ring, slide the

lower bearing cone onto the cylinder rod

with the bevel pointing away from the

cylinder and seat it on the cylinder head.

Then coat the bevel of the cone with “never

seize”. Note that the release cylinder boss

and the lower bearing cup should still be in

place on the underside of the main frame.

WARNING

Provide safe work platforms for all

maintenance and operational requirements.

Death or serious injury may result from a fall

from an unstable or inadequate work

platform. Work platforms must be anchored

to provide adequate stability and must be

structurally able to support the loads

sustained

during

any

maintenance

operation. Workers must also be prepared

with fall arrest harness equipment. Follow all

OSHA, MSHA and site specific guidelines

for the requirements of working from

elevated platforms.

Summary of Contents for MP1000

Page 1: ...Nordberg MP Series Cone Crusher ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 8: ......

Page 64: ...SECTION 0 SAFETY 0 56 MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL ...

Page 66: ......

Page 74: ......

Page 154: ...Countershaft and Countershaft Box Callout Description 1 Countershaft 2 Countershaft box 1 2 ...