SECTION 2

TROUBLESHOOTING

23

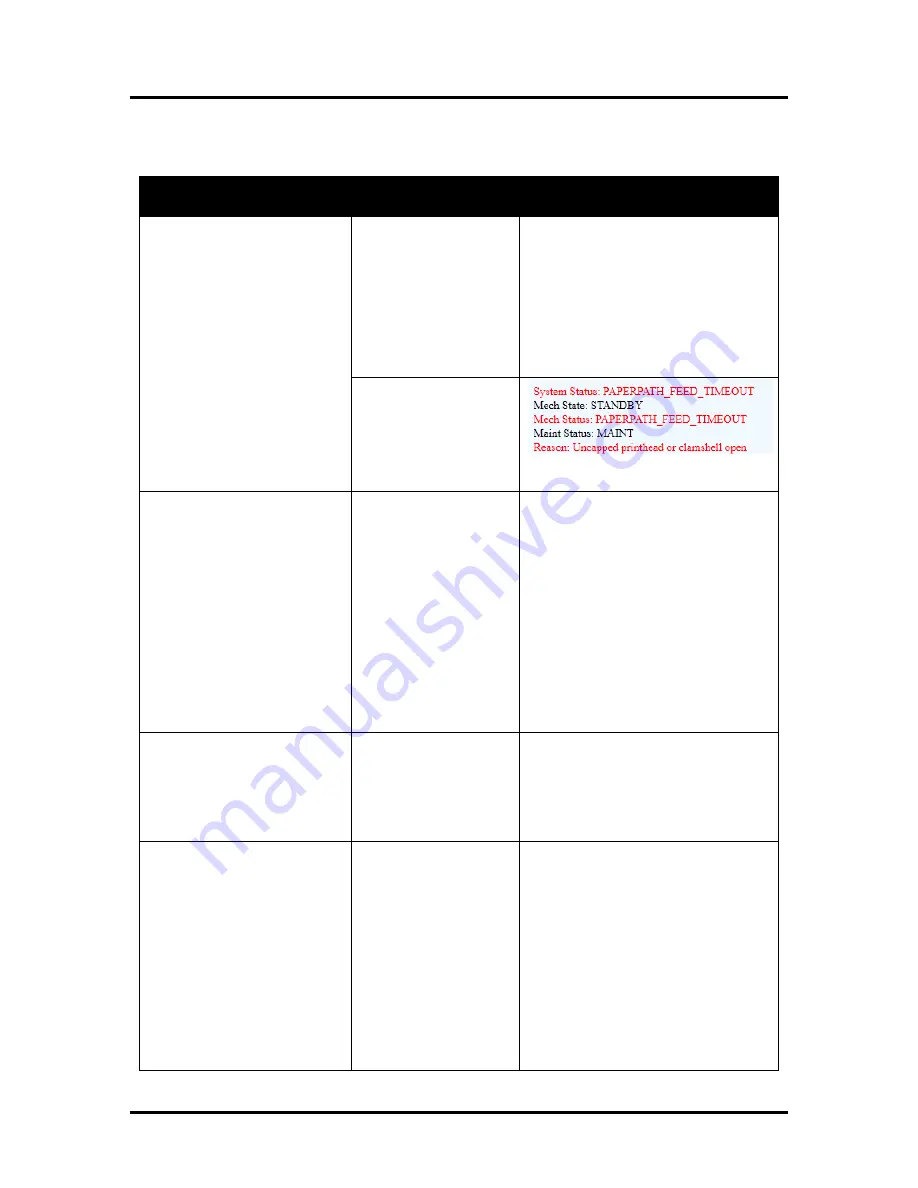

Toolbox System Status Messages

Displayed, in

red

, in the M Series Toolbox utility.

SYSTEM STATUS

PROBLEM

SOLUTION

PAPERPATH_FEED_TIME

OUT

Out of Paper

Media is not reaching

the print engine.

Hesitation in media feed.

Load media into printer and press the

PAPER/RESUME button.

If media is present; check/adjust the

guides and separators.

Tip: It is also possible to get this error if

the media jams after reaching the

Paperpath Exit sensor, and the trailing

edge is still in the Entry sensor. See

below.

Possible Paper Jam; if

error is shown in

combination with

“Reason: Uncapped

printhead or clamshell

open”

message.

See “Paperpath_Paperjam” solutions.

PAPERPATH_PAPERJAM

Paperpath: Entry:Yes Exit:Yes

or

Paperpath: Entry: No Exit:Yes

or

Paperpath: Entry:Yes Exit:No

No = not blocked

Yes = blocked (interrupted)

Paper Jam

Media jam detected.

Printer has detected that

one of the media sensors

is blocked (interrupted).

Carefully open the Clamshell, remove

jammed Media from printer and close

the Clamshell. The System Status

message in

red

should go away.

The toolbox “Paperpath” line should

change to:

Paperpath: Entry: No Exit: No

After you clear the jam you can;

Press RESUME button to continue

printing.

Press the CANCEL button to cancel the

job, and then manually clear the job

from the computer’s print queue.

DOOROPEN_FRONT

Printer has detected that

the “Clamshell” is open.

Sensor cable P2002

unplugged?

Verify that the “Clamshell” is closed

and securely latched at both sides.

If closed; check the clamshell latch &

switch. Use Scan Sensors feature in the

Toolbox Service Menus to test

clamshell switch.

DATA_PATH_UNDERRUN

Media is not making it

from the entry sensor to

the exit sensor in the

appropriated time.

Possible issue with

format or orientation of

job being sent.

Possible issue with

Encoder in Print Engine.

Resistance to Print

Engine drive or media

movement.

Check/clean transport rollers.

Check/clean sensors.

Try changing the orientation setting in

the software/driver or setting a different

media size.

Check/clean encoder and wheel.

Check for mechanical issues that may

cause resistance to transport or media

movement.

Summary of Contents for AS-1180C

Page 75: ...SECTION 4 DISASSEMBLY AND ASSEMBLY 73 a J1002 Cable J1002 Socket Location Connection ...

Page 76: ...SECTION 4 DISASSEMBLY AND ASSEMBLY 74 b J1000 Cable J1000 Socket Location Connection ...

Page 77: ...SECTION 4 DISASSEMBLY AND ASSEMBLY 75 c J551 Cable J551 Socket Location Connection ...

Page 78: ...SECTION 4 DISASSEMBLY AND ASSEMBLY 76 d J703 Cable J703 Socket Location Connection ...

Page 79: ...SECTION 4 DISASSEMBLY AND ASSEMBLY 77 e P2002 Cable P2002 Socket Location Connection ...

Page 80: ...SECTION 4 DISASSEMBLY AND ASSEMBLY 78 f P2004 Cable P2004 Socket Location Connection ...

Page 81: ...SECTION 4 DISASSEMBLY AND ASSEMBLY 79 g P2006 Cable P2006 Socket Location Connection ...

Page 82: ...SECTION 4 DISASSEMBLY AND ASSEMBLY 80 h J35 Cable J35 Socket Location Connection ...

Page 83: ...SECTION 4 DISASSEMBLY AND ASSEMBLY 81 i P1 Cable P1 Socket Location Connection ...

Page 84: ...SECTION 4 DISASSEMBLY AND ASSEMBLY 82 j P2005 Cable P2005 Socket Location Connection ...

Page 85: ...SECTION 4 DISASSEMBLY AND ASSEMBLY 83 k P2003 Cable P2003 Socket Location Connection ...

Page 86: ...SECTION 4 DISASSEMBLY AND ASSEMBLY 84 l J20 Cable J20 Socket Location Connection ...

Page 87: ...SECTION 4 DISASSEMBLY AND ASSEMBLY 85 m J2001 Cable J2001 Socket Location Connection ...

Page 180: ......

Page 181: ...Copyright Neopost USA 2014 ...