Page 96 P/N 03521015 Rev U1

Bio-Medical Devices Intl

17171 Daimler Street Irvine, CA 92614 800-443-3842 www.maxair-systems.com

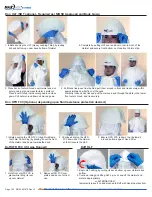

26. Single XP HFR Hoods with Heavy Loading Filter (HLF) and

optional HFR FCC

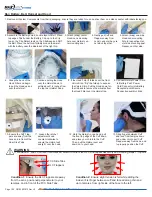

WARNING

Use only if package is received unopened and contents are

undamaged. If damage is noted, contact the shipper for replacement

or repair.

Prior to using any MAXAIR

®

System or component, be sure to be

familiar with the system’s NIOSH approved configuration.

DO NOT use if any component is damaged. If any components are

damaged or contaminated and therefore unfit for safe and effective

use, they should be replaced immediately.

Only trained and experienced personnel who have read and under-

stand the User’s Instructions should use this product.

Failure to follow the User’s Instructions, these and in the MAXAIR

Systems User’s Instructions, P/N 03521015, may be hazardous to

the user’s health.

The institution using this product in any application is responsible for

determining the appropriateness of this equipment relative to regula-

tory requirements. Bio-Medical Devices Intl, Inc. does not recom-

mend the appropriate systems for a particular institution or facility.

Use only MAXAIR Systems/ NIOSH approved compatible

components.

NOT for use in atmospheres immediately dangerous to life or health

(IDLH), and atmospheres containing less than 19.5% oxygen, or

more than 25% oxygen.

Flammability Level I: fabric may burn if exposed to open flame.

Follow current local regulations governing biohazard waste to safely

dispose of used shrouds.

If you need more information, contact your BMDI Sales

Representative, or call BMDI customer service at 1-800-443-3842.

Symbol Definitions

Warning, Caution, or Note Order Number

Intended Use

The MAXAIR

®

CAPR

®

Hood Systems are intended to filter

aerosolized and droplet particulates and provide high level fluid

resistance.

Hoods are designed for single use applications.

Hood Specifications

Temperature Limits:

49

0

C maximum

Materials:

Regulatory

NIOSH

Typical Hood System Components

1 The 2500-36TSC is an alternate to the 2500-37TSC.

O.N. 2271PB-07SM

(Small-Medium)

P/N 07831155

O.N. 2271PB-07ML

(Medium-Large)

P/N 07831156

*one 2170-27 (07831205) HLF is

included with each Hood

1. 2081-03 Helmet

2. 2271PB-07 Hood w/2170-27 HLF

3. 2061-05 HFR FCC

4. 2500-37TSC Battery

1

5. 2000-76 Battery Belt

6. 2600-01 Battery Charger

MATERIAL

TYPE

FLUID RESISTANCE

Body (Shroud) Polypropylene

ASTM F1671

Lens

Polycarbonate

ASTM F1671

Hood Filter

Polypropylene

AATCC TM127

HLF

Polypropylene/

modacrylic blend

General particle filter

material

O.N.

1

5

6

2

4

3