Ref.: 3DWA - SM Ver.1.8

20

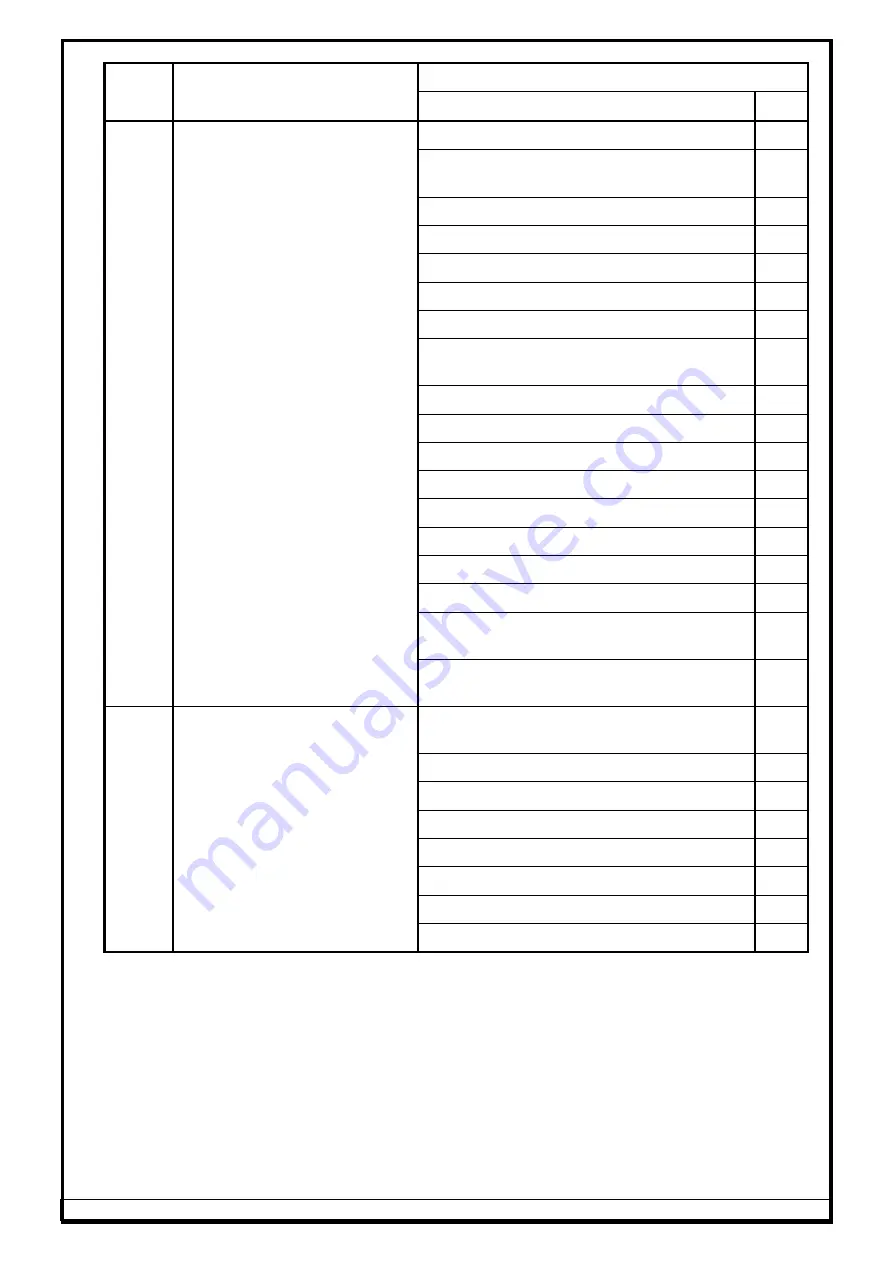

For In-Lift models

Package

No.

Package description

Package contents

Part name

Qty

1/2

Vertical column wooden box

Camera mounted Vertical column (LH)

1 No.

Camera mounted Vertical column (RH) with

Hub board

1 No.

Wheel bracket holding post, 2 holder

2 Nos.

Mini Target plate-Front Left in EPE foam

1 No.

Mini Target plate-Front Right in EPE foam

1 No.

Target plate-Rear Left in EPE foam

1 No.

Target plate-Rear Right in EPE foam

1 No.

PC Console box

Desktop computer (*)

1 No.

Monitor

1 No.

Printer (*)

1 No.

Multimedia speaker (*)

1 Pair

Windows Embedded OS CD (*)

1 No.

"Align+" SW CD

1 No.

Calibration data CD

1 No.

Fuse, 3A, Ø5x20mm, Slow blow type

1 No.

Fuse, 5A, Ø6.35x31.8mm, Slow blow type

1 No.

Wheel bracket corrugated box

Wheel bracket in Thermocole box (*)

4 Nos.

Rotary plate wooden box

Rotary plate (*)

2 Nos.

2/2

Accessories wooden box

Accessories mounting column with Interface

box

1 No.

Monitor Mounting stand

1 No.

CPU Tray

1 No.

Keyboard tray

1 No.

Printer tray

1 No.

Steering lock

1 No.

Brake pedal lock

1 No.

Wheel stopper

2 Nos.

Summary of Contents for Fox 3D Smart Mobile PT

Page 9: ...Ref 3DWA SM Ver 1 8 6 PIT DIMENSIONS Max Wheel base 3 2 4metre For VH model Fig 3...

Page 16: ...Ref 3DWA SM Ver 1 8 13 FOUR POST LIFT DIMENSIONS Max Wheel base 4 metre For VH model Fig 10...

Page 19: ...Ref 3DWA SM Ver 1 8 16 FOUR POST LIFT DIMENSIONS Max Wheel base 4metre For In Lift Fig 13...

Page 25: ...Ref 3DWA SM Ver 1 8 22 VH model 12 3 7 8 9 4 5 2 1 10 11 11 13 14 Fig 15...

Page 26: ...Ref 3DWA SM Ver 1 8 23 AVH model 12 3 7 8 9 4 5 2 1 11 13 14 6 Fig 16...

Page 69: ...Ref 3DWA SM Ver 1 8 66 For Drive Through model Fig 118...

Page 70: ...Ref 3DWA SM Ver 1 8 67 Fig 119...

Page 72: ...Ref 3DWA SM Ver 1 8 69 For Drive Through model Fig 121...

Page 73: ...Ref 3DWA SM Ver 1 8 70 For In Lift model 865 865 Fig 122...

Page 92: ...Ref 3DWA SM Ver 1 8 89 10 DIAGRAMS 10 1 BLOCK DIAGRAM Fig 154...

Page 93: ...Ref 3DWA SM Ver 1 8 90 10 2 WIRING DIAGRAM 10 2 1 PT VH MODEL Fig 155...

Page 94: ...Ref 3DWA SM Ver 1 8 91 Fig 156...

Page 95: ...Ref 3DWA SM Ver 1 8 92 10 2 2 AVH MODEL Fig 157...

Page 96: ...Ref 3DWA SM Ver 1 8 93 Fig 158...

Page 97: ...Ref 3DWA SM Ver 1 8 94 10 2 3 IN LIFT MODEL Fig 159...

Page 98: ...Ref 3DWA SM Ver 1 8 95 Fig 160...