26

degrees.

The Tape is defective.

Use another Tape.

♦

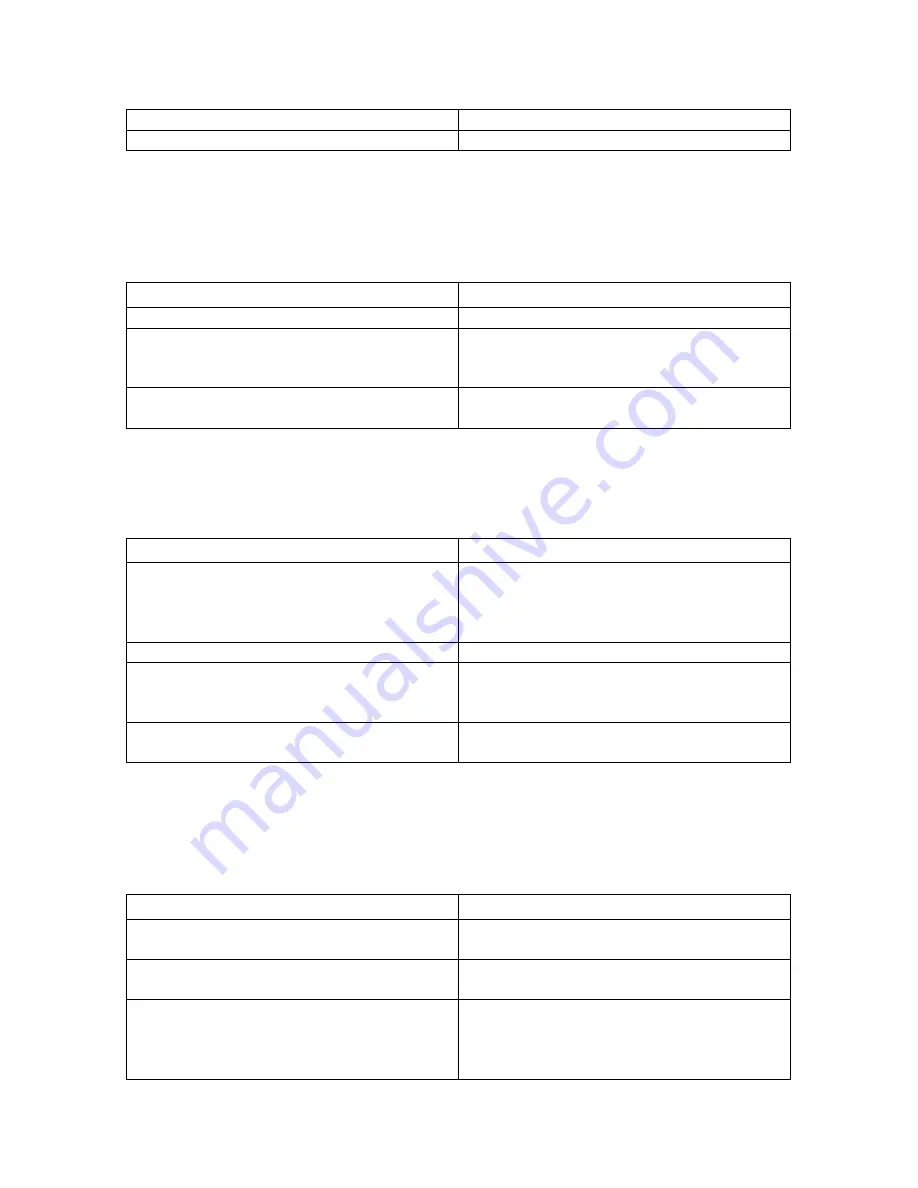

The Tape is cut during sectioning.

Cause

Solution

The block face is not flat.

Align and trim the block to obtain a flat face.

The adhesive on the Tape overhangs the block

and snags on the knife.

Position the Tape on the block so that

no

adhesive is exposed to the knife when cutting

the section.

The knife and/or the block are not be properly

tightened.

Check the knife and block for looseness and

tighten all screws and clamps as needed.

♦

The captured section on the Tape is not intact.

Cause

Solution

The knife is dull.

If using a disposable blade, shift to a different

portion of the blade’s edge or replace the

blade. If using a stainless steel or tungsten-

carbide knife, sharpen the knife.

There is dirt on the Tape

Use a fresh, clean and cold Tape.

Bubbles form while laminating the Tape to the

block face.

Apply the Tape “like wallpaper” to the block

face while laminating with the cold Roller. If

bubbles are still visible, reapply the Tape.

There is vibration in the microtome (thick/thin,

chatter, etc.)

Check the knife and block for looseness and

tighten all screws and clamps as needed.

♦

The section on the Tape does not transfer properly to the Slide.

Cause

Solution

The mylar film on the Slide has not been

removed.

Remove the mylar film.

The adhesive layer on the Slide is not facing

up.

Position the Slide on the Blue Pad so the

adhesive layer faces up.

The Slide is too cold or too warm.

See the

Mech and ECU Troubleshooting

Guide

for the left LED on the ECU (labeled

Pad) always displaying either a solid red or

flashing red light.