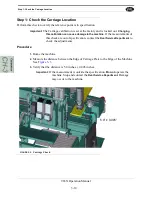

Step 3: Calibrate the Tools

3-16

965X Operation Manual

Predrill

Follow the steps in

Process to Calibrate the Tools” on page 3-13.

If the predrill output is out of

calibration, measure and compare against the

Door Job

specifications. If needed, input the offset

polarity as seen in the

Figure 3- 9

FIGURE 3- 9.

Predrill Axis Direction

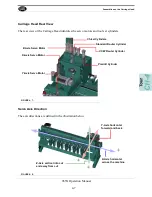

Process to Calibrate the Chisels

For instructions about entering calibration data,

see “How to Enter Calibration Data” on page 3-6.

1.

Create a

Door Job

of a cut of your choice with a depth that does not go through the

jamb. The example in used in this section is a Jamb Lock Cut.

2.

Add

Door Job

to the

Queue

.

3.

Once the cut is machined, check the corners of the cut. If the corners are not in the

specifications, find which corner needs to be calibrated.

4.

Perform the Left Hand Rule at the lock side of the door to determine axis direction.

See illustration below.

• If the chisel cut is out of specification in the

length

of the jamb, the

X-Axis

needs

to be adjusted.

+

Z

+

X

+

Y

-

Y

-

Z

-

X

Summary of Contents for 965X

Page 103: ......