Step 3: Calibrate the Tools

3-15

965X Operation Manual

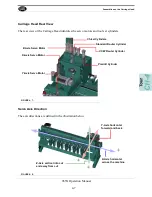

Sample Calibration Cut

shows an example between an actual cut and a expected cut. The expected cut is the

darker portion of the illustration. The actual cut is the transparent portion of the illustration.

Lock Plate Example:

The Lock Plate is shown looking directly at the jamb face.

• The actual cut of the Lock Plate is out of specification in the X-Axis

• Using

Figure 3- 6

and

Figure 3- 7

as a reference, enter the measured difference

between the actual and expected cut.

• In the case below the Lock Plate shape is longer in the Positive X axis. Enter a the

measured difference (negative value) in the Offset Box to bring into specification.

Depth of Rectangle Cut:

The Rectangle is shown looking down the top edge of the jamb.

• The actual cut deeper than the expected cut and is out of calibration in the Z-Axis.

• Using

Figure 3- 6

and

Figure 3- 7

as a reference, enter the measured difference

between the actual and expected cut.

• In the case below enter the measured difference (negative value) in the Offset Box

to bring into specification.

FIGURE 3- 8.

Example Cuts

-

X

-

Z

Measure the actual cut.

input the measured differences in the Offset Box.

Measured Difference

Measured Difference

Lock Plate

Rectangle Cut

Summary of Contents for 965X

Page 103: ......