AKD Installation | 7 Technical description and data

7.16.8.3 Functional test

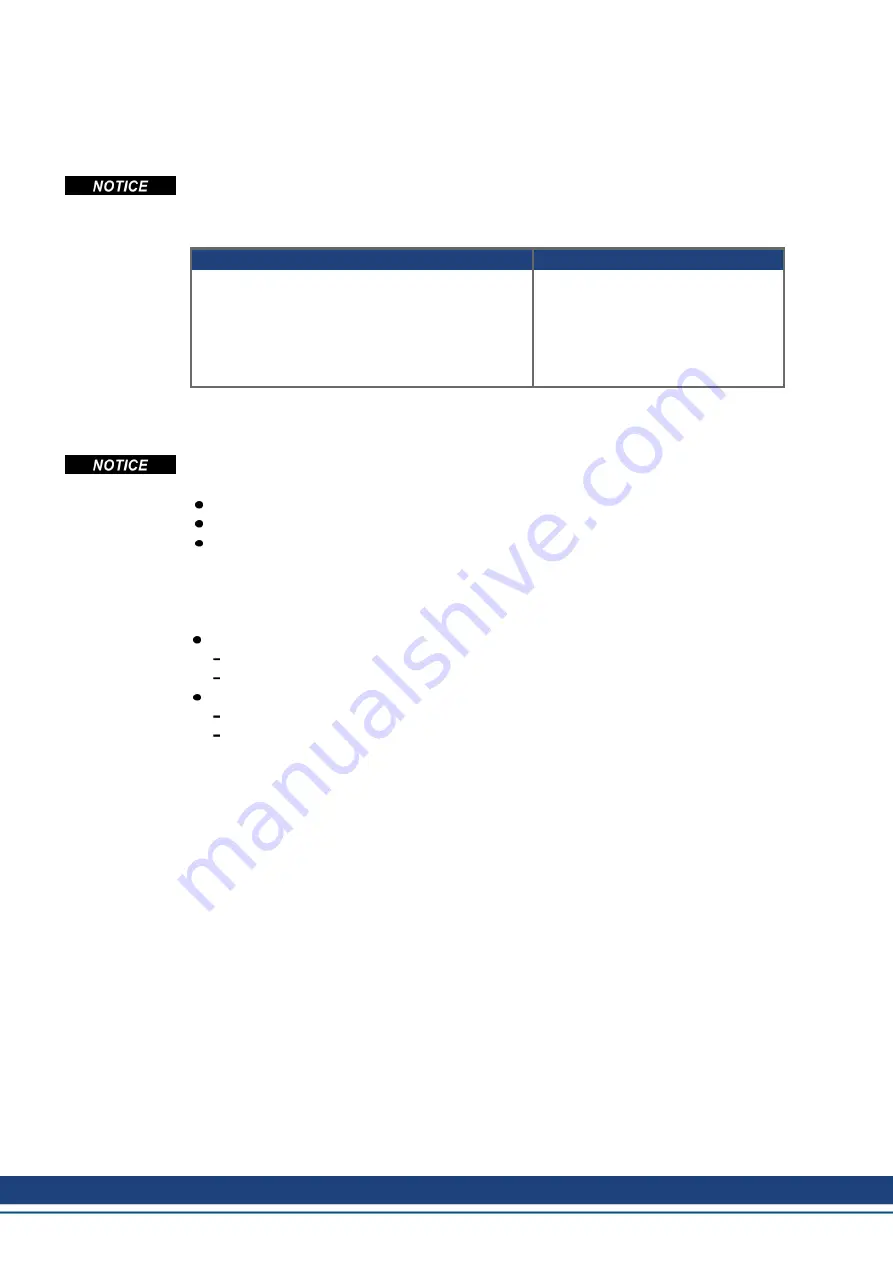

SIngle Channel control and Dual Channel control, SIL CL2 / PLd

You must test the STO function after initial start of the drive, after each interference into the

wiring of the drive, or after exchange of one or several components of the drive.

Method 1, drive remain enabled

Method 2, drive disabled

1. Stop drive, with setpoint 0V. Keep drive enabled.

DANGER: Do not enter hazardous area!

2. Activate the STO function for example by open-

ing protective screen.

3. The fault contact opens, the net contactor

releases, and the drive displays fault F602.

1. Stop all drives, with setpoint 0V,

disable drive (Enable=0V).

2. Activate the STO function, for

example, by opening protective

screen

3. The drive displays warning n602.

Dual Channel control, SIL CL3 / PLe

To achieve PLe / SIL CL3, the safe switching of the pulse inhibitor must be tested peri-

odically by analyzing the feedback signal from a safety control:

at the start of a system,

at the restart after triggering a protective device,

at least every 8 hours by the operator.

The inputs STO-ENABLE 1 and STO-ENABLE 2 are switched in turns according to a defined

test sequence. The switching state of the pulse inhibitor is available at the STO-Status out-

puts of the AKD and must be analyzed to achieve a sufficient diagnostic cover ratio:

Diagnostic with external not safe controller, test with dynamic sequence:

test cycle: with each device start, minimum once per day.

diagnostic cover ratio: 60 %

Diagnostic with external safe controller, test with dynamic sequence.

test cycle: with each device start, minimum once per day.

diagnostic cover ratio: 90 %

The test sequence for the functional test of the safe pulse inhibitor must be performed as

shown in the following time diagram.

64

Kollmorgen | kdn.kollmorgen.com | October 2017