1.

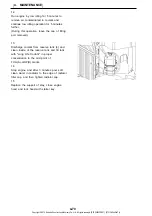

Place a container to receive drained fuel

under the fuel filter (1).

2.

Loosen the air bleeder plug (2) and send

fuel pumping the priming pump (3).

Put the rag to the air bleeder plug to

absorb drained fuel.

3.

Pump the priming pump (3) until the fuel

without bubbles comes out from the air

bleeder plug (2).

4.

Tighten the air bleeder plug (2) if the fuel

without bubbles comes out from the air

bleeder plug.

(Tightening torque :

2±0.2 N-m {1.4±0.1 lbf-ft})

5.

Pump the priming pump (3) again more

than 20 times.

6.

After air bleeding is completed, wipe off

any leaked fuel. Run the engine and

check for fuel leakage.

4

D.

Bleeding Air from the Fuel System

After replacing the fuel filter or if you have run out of fuel, air might have entered the fuel system and

a simple supply of fuel cannot start the engine. Bleed the air according to the following procedure:

-Be sure to drain the fuel into a container to ensure safety and keep the ground clean.

-Wipe away all spilled fuel before starting up the engine.

After engine has started, check for fuel leaks.

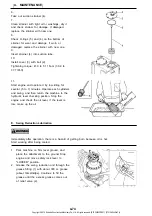

E.

Cleaning Fuel Tank Cap and Strainer

1.

Remove cap with starter key.

2.

Check cap seal for damage, and if damaged replace it with new one.

3.

Clean strainer with light oil and attach it in place. If damaged, replace it with new one.

4.

Attach cap and lock it with starter key.

[

4. MAINTENANCE

]

4-59

Copyright © 2015 Kobelco Construction Machinery Co.,Ltd. All rights reserved. [S2YF00022ZE01] [0731CsCshWbYs]