Exhaust gas recirculation occurs only in the partial load area of the engine because the engine

runs particularly lean in this area. Exhaust gas recirculation is not practical in cold start, warm-up

and full load.

Exhaust gas turbo-charging:

The performance of the combustion engine can be enhanced by means of turbo-charging. A turbo‐

charger compresses the air to allow more oxygen to flow into the combustion chamber. As a result,

more fuel can be combusted and the engine performance increases accordingly. The turbocharger

is driven by exhaust gas which makes turbo-charged engines very efficiently.

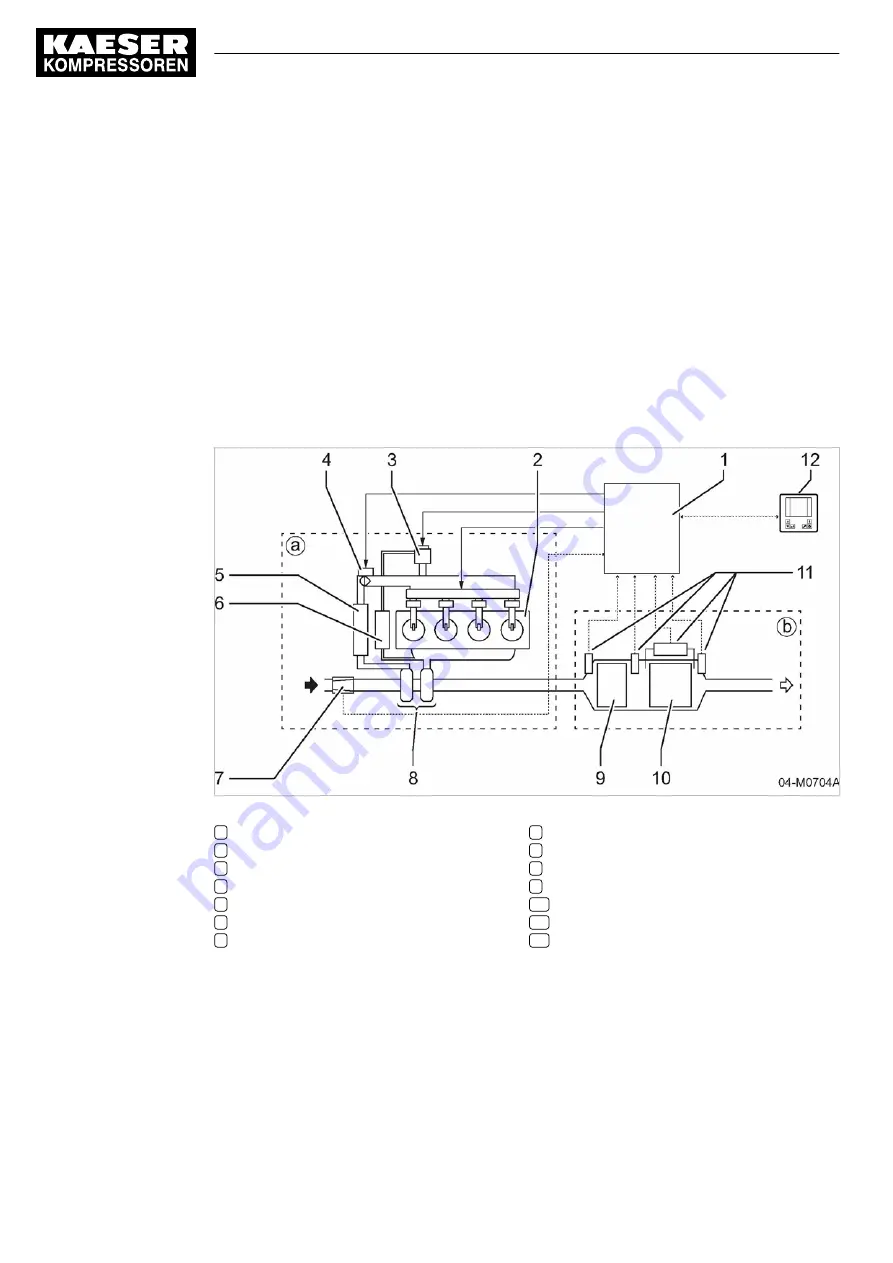

4.7.2 Exhaust gas treatment system

The exhaust gas treatment system primarily contributes to limiting the exhaust gas emissions of

the machine.

Fig. 13 Principle of treatment devices

1

Engine control unit (ECU)

a

Common rail system

2

Engine block

3

Exhaust gas return valve (EGR)

4

Inlet throttle

5

Intercooler

6

Cooler exhaust gas return (EGR)

7

Air flow meter

8

Turbocharger

b

Exhaust gas treatment system

9

Diesel oxidation catalytic converter (DOC)

10

Diesel particulate filter (DPF)

11

Sensors

12

SIGMA CONTROL SMART controller

Diesel oxidation catalytic converter (DOC):

The diesel oxidation catalytic converter uses the fuel which has not been burnt during final injection

for the active regeneration of the diesel particulate filter. The diesel oxidation catalytic converter

serves a source of heat for the regeneration of the diesel particulate filter.

4

Design and Function

4.7

Exhaust gas after-treatment

44

Operator Manual Portable Rotary Screw Compressor

MOBILAIR M58utility SIGMA CONTROL SMART

No.: 901779 08 USE