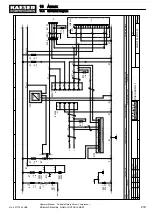

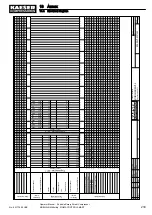

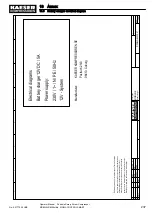

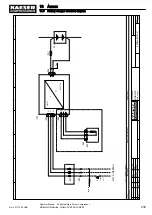

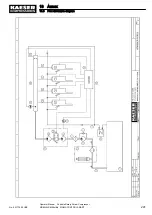

MOBILAIR M58UT.2

SFA58UT.SK-03013.04

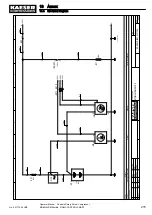

-T27

-K27

GPS Modem

GPS Modem

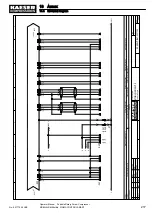

1

2

3

4

5

6

7

8

page

Circuit diagram

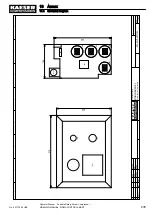

GPS Modem - option oc

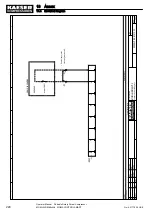

GPS antenna

-K27

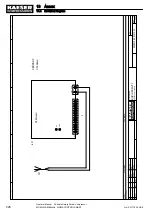

GPS Modem

/2.8

option oc

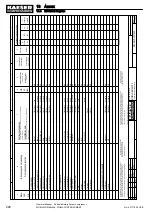

9 Sht.

a

b

c

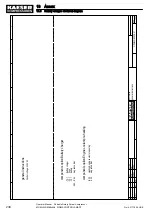

Change

Date

Date

Drawn

Released

Name

9

07.05.2021

=SK

+

Function:

Group of functions:

D

Sitter

Fischer C.

GPS

GSM

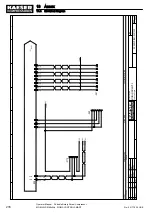

1

2

3

4

5

ON

Status

6

7

8

9

10

11

12

13

14

13 Annex

13.4 Electrical Diagram

226

Operator Manual Portable Rotary Screw Compressor

MOBILAIR M58utility SIGMA CONTROL SMART

No.: 901779 08 USE