SECTION 7 - BASIC ELECTRICAL INFORMATION & SCHEMATICS

3121290

– JLG Lift –

7-3

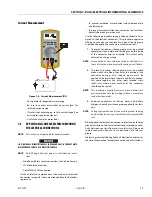

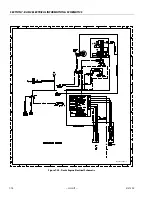

Current Measurement

• Set up meter for expected current range

• Be sure to connect meter leads to correct jacks for

selected current range

• If meter is not auto ranging, set it to correct range (See

multi meter’s operation manual)

• Use firm contact with meter leads

7.3

APPLYING SILICONE DIELECTRIC COMPOUND

TO ELECTRICAL CONNECTIONS

NOTE:

This section is not applicable for battery terminals.

JLG P/N 0100048 DIELECTRIC GREASE (NOVAGARD G661) IS THE ONLY MATE-

RIAL APPROVED FOR USE AS A DIELECTRIC GREASE.

NOTE:

Do NOT apply dielectric grease to the following connec-

tions:

• Main Boom Rotary sensor connections (on Celesco Sensor),

• LSS Modules connections,

• Deutz EMR 2 ECM connection.

Silicone Dielectric Compound must be used on all electrical

connections except for those mentioned above for the follow-

ing reasons:

• To prevent oxidation at mechanical joint between male

and female pins.

• To prevent electrical malfunction caused by low level con-

ductivity between pins when wet.

Use the following procedure to apply Silicone Dielectric Com-

pound to the electrical connectors. This procedure applies to

all plug connections not enclosed in a box. Silicone grease

should not be applied to connectors with external seals.

1.

To prevent oxidation, silicone grease must be packed

completely around male and female pins on the inside

of the connector prior to assembly. This is most easily

achieved by using a syringe.

NOTE:

Over a period of time, oxidation increases electrical resis-

tance at the connection, eventually causing circuit failure.

2.

To prevent shorting, silicone grease must be packed

around each wire where they enter the outside of the

connector housing. Also, silicone grease must be

applied at the joint where the male and female connec-

tors come together. Any other joints (around strain

reliefs, etc.) where water could enter the connector

should also be sealed.

NOTE:

This condition is especially common when machines are

pressure washed since the washing solution is much more

conductive than water.

3.

Anderson connectors for battery boxes and battery

chargers should have silicone grease applied to contacts

only.

NOTE:

Curing-type sealants can also be used to prevent shorting

and would be less messy, but make future pin removal diffi-

cult.

When applied to electrical connections, dielectric grease helps

prevent corrosion of electrical contacts and improper conduc-

tivity between contacts from moisture intrusion. Open and

sealed connectors benefit from application of dielectric

grease.

Dielectric grease shall be applied to all electrical connectors at

the time of connection (except those noted under Exclusions).

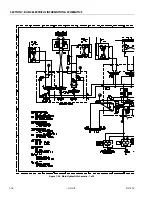

Figure 7-4. Current Measurement (DC)

Summary of Contents for 450A II Series

Page 46: ...SECTION 3 CHASSIS TURNTABLE 3 6 JLG Lift 3121290 Figure 3 4 Drive Hub 4WD Front Only ...

Page 79: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 39 Figure 3 32 Swing Bearing Drive ...

Page 101: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 61 Figure 3 42 Auxiliary Pump ...

Page 113: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 73 Figure 3 53 EMR2 Fault Codes Sheet 1 of 5 ...

Page 114: ...SECTION 3 CHASSIS TURNTABLE 3 74 JLG Lift 3121290 Figure 3 54 EMR2 Fault Codes Sheet 2 of 5 ...

Page 115: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 75 Figure 3 55 EMR2 Fault Codes Sheet 3 of 5 ...

Page 116: ...SECTION 3 CHASSIS TURNTABLE 3 76 JLG Lift 3121290 Figure 3 56 EMR2 Fault Codes Sheet 4 of 5 ...

Page 117: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 77 Figure 3 57 EMR2 Fault Codes Sheet 5 of 5 ...

Page 159: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 119 ...

Page 161: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 121 ...

Page 163: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 123 ...

Page 165: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 125 ...

Page 173: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 133 Sensor Transducer Type ...

Page 177: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 137 Sensor Transducer Type ...

Page 179: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 139 ...

Page 181: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 141 ...

Page 183: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 143 ...

Page 185: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 145 ...

Page 187: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 147 ...

Page 203: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 163 ...

Page 207: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 167 ...

Page 217: ...SECTION 4 BOOM PLATFORM 3121290 JLG Lift 4 5 Figure 4 2 Boom Limit Switches ...

Page 310: ...SECTION 5 HYDRAULICS 5 70 JLG Lift 3121290 NOTES ...

Page 312: ...SECTION 6 JLG CONTROL SYSTEM 6 2 JLG Lift 3121290 Figure 6 2 Controller Block Diagram 0 ...

Page 370: ...SECTION 6 JLG CONTROL SYSTEM 6 60 JLG Lift 3121290 NOTES ...

Page 394: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 7 24 JLG Lift 3121290 NOTES ...

Page 395: ......