SECTION 5 - HYDRAULICS

5-44

– JLG Lift –

3121290

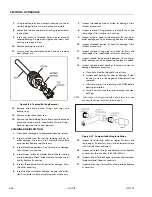

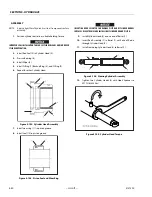

7.

Using suitable protection, clamp cylinder rod in a vise or

similar holding fixture as close to piston as possible.

8.

Loosen and remove cap screws attaching tapered bush-

ing to piston.

9.

Insert cap screws in threaded holes in outer piece of

tapered bushing. Progressively tighten cap screws until

bushing is loose on piston.

10.

Remove bushing from piston.

11.

Screw piston counter-clockwise by hand and remove

from cylinder rod.

Figure 5-86. Tapered Bushing Removal

12.

Remove and discard piston O-rings, seal rings, and

backup rings.

13.

Remove piston spacer from rod.

14.

Remove rod from holding fixture. Remove cylinder head

gland and retainer plate, if applicable. Discard O-rings,

back-up rings, rod seals, and wiper seals.

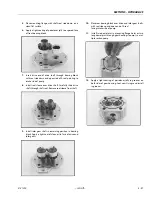

CLEANING AND INSPECTION

1.

Clean parts thoroughly with approved cleaning solvent.

2.

Inspect cylinder rod for scoring, tapering, ovality, or

other damage. If necessary, dress rod with Scotch Brite

or equivalent. Replace rod if necessary.

3.

Inspect threaded portion of rod for excessive damage.

Dress threads as necessary.

4.

Inspect inner surface of cylinder barrel tube for scoring

or other damage. Check inside diameter for tapering or

ovality. Replace if necessary.

5.

Inspect threaded portion of barrel for damage. Dress

threads as necessary.

6.

Inspect piston surface for damage, scoring, and distor-

tion. Dress piston surface or replace piston as necessary.

7.

Inspect threaded portion of piston for damage. Dress

threads as necessary.

8.

Inspect seal and O-ring grooves in piston for burrs and

sharp edges. Dress surfaces as necessary.

9.

Inspect cylinder head inside diameter for scoring or

other damage, ovality, and tapering. Replace as needed.

10.

Inspect threaded portion of head for damage. Dress

threads as necessary.

11.

Inspect seal and O-ring grooves in head for burrs and

sharp edges. Dress applicable surfaces as necessary.

12.

Inspect cylinder head outside diameter for scoring or

other damage, ovality, and tapering. Replace as needed.

13.

Inspect rod and barrel bearings for excessive wear or

damage. Replace as necessary.

a. Clean hole, (steel bushing) of burrs, dirt, etc.

b. Inspect steel bushing for wear or damage. If steel

bushing is worn or damaged, rod/barrel must be

replaced.

c. Lubricate inside of steel bushing with WD40 before

bearing installation.

d. Using a correct size arbor, press bearing into steel

bushing.

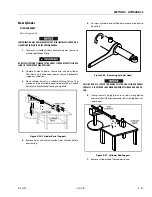

NOTE:

Lubrication is not required with nickel plated pins and

bearings. Install pin in composite bushing dry.

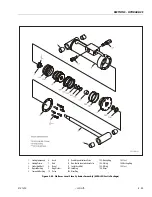

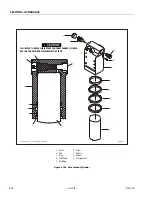

Figure 5-87. Composite Bushing Installation

14.

Inspect travel limiting collar or spacer for burrs and

sharp edges. If necessary, dress inside diameter surface

with Scotch Brite or equivalent.

15.

Inspect port block fittings and holding valves. Replace

as necessary. Torque valves to 30 ft-lb (40Nm).

16.

Inspect oil ports for blockage or presence of dirt or other

foreign material. Repair as necessary.

17.

Inspect piston rings for cracks or other damage. Replace

as necessary.

Summary of Contents for 450A II Series

Page 46: ...SECTION 3 CHASSIS TURNTABLE 3 6 JLG Lift 3121290 Figure 3 4 Drive Hub 4WD Front Only ...

Page 79: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 39 Figure 3 32 Swing Bearing Drive ...

Page 101: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 61 Figure 3 42 Auxiliary Pump ...

Page 113: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 73 Figure 3 53 EMR2 Fault Codes Sheet 1 of 5 ...

Page 114: ...SECTION 3 CHASSIS TURNTABLE 3 74 JLG Lift 3121290 Figure 3 54 EMR2 Fault Codes Sheet 2 of 5 ...

Page 115: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 75 Figure 3 55 EMR2 Fault Codes Sheet 3 of 5 ...

Page 116: ...SECTION 3 CHASSIS TURNTABLE 3 76 JLG Lift 3121290 Figure 3 56 EMR2 Fault Codes Sheet 4 of 5 ...

Page 117: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 77 Figure 3 57 EMR2 Fault Codes Sheet 5 of 5 ...

Page 159: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 119 ...

Page 161: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 121 ...

Page 163: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 123 ...

Page 165: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 125 ...

Page 173: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 133 Sensor Transducer Type ...

Page 177: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 137 Sensor Transducer Type ...

Page 179: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 139 ...

Page 181: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 141 ...

Page 183: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 143 ...

Page 185: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 145 ...

Page 187: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 147 ...

Page 203: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 163 ...

Page 207: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 167 ...

Page 217: ...SECTION 4 BOOM PLATFORM 3121290 JLG Lift 4 5 Figure 4 2 Boom Limit Switches ...

Page 310: ...SECTION 5 HYDRAULICS 5 70 JLG Lift 3121290 NOTES ...

Page 312: ...SECTION 6 JLG CONTROL SYSTEM 6 2 JLG Lift 3121290 Figure 6 2 Controller Block Diagram 0 ...

Page 370: ...SECTION 6 JLG CONTROL SYSTEM 6 60 JLG Lift 3121290 NOTES ...

Page 394: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 7 24 JLG Lift 3121290 NOTES ...

Page 395: ......