SECTION 3 - CHASSIS & TURNTABLE

3-86

– JLG Lift –

3121290

Heated Exhaust Gas Oxygen Sensor

There are two Heated Exhaust Gas Oxygen Sensors (HEGO).

The first HEGO is mounted in the exhaust system downstream

of the engine. It is used to measure the amount of oxygen

present in the exhaust stream and communicate that to the

ECM via an electrical signal. The amount of oxygen present in

the exhaust stream indicates whether the fuel/air ratio is too

rich or too lean. If the HEGO sensor signal indicates exhaust

stream is too rich, the ECM will decrease or lean the fuel mix-

ture during engine operation. If mixture is too lean the ECM

will richen the mixture. The ECM continuously monitors the

HEGO sensor output. If a rich or lean condition is present for an

extended period of time, and the ECM cannot correct the con-

dition, the ECM sets a diagnostic code and turns on the MIL

light in control box.

The second HEGO is mounted in the exhaust system after the

muffler. It measures the amount of oxygen in the exhaust sys-

tem after the catalyst treatment has been completed in the

muffler. If the ECM detects that the catalytic action in the muf-

fler is not sufficient and fuel correction cannot correct the mal-

function the MIL light is illuminated in the control box and a

DTC code will stored in the computer.

THE HEATED EXHAUST GAS OXYGEN SENSOR IS AN EMISSION CONTROL

DEVICE. IF THE HEGO FAILS TO OPERATE, REPLACE IT WITH AN OEM REPLACE-

MENT PART. THE HEGO SENSOR IS SENSITIVE TO SILICONE OR SILICONE

BASED PRODUCTS AND CAN BECOME CONTAMINATED. AVOID USING SILICONE

SEALERS OR HOSES TREATED WITH SILICONE LUBRICANTS IN THE AIR

STREAM OR FUEL LINES.

Gasoline Multi Point Fuel Injection System (MPFI)

The primary components of the Gasoline Multi Point Fuel

Injection (MPFI) fuel system are the fuel tank, electric fuel

pump, fuel pressure and temperature sensor manifold, fuel fil-

ter, and fuel rail.

Gasoline Fuel Pump

Gasoline is stored as a liquid in the fuel tank and in drawn into

the fuel system by an electric fuel pump. The fuel pump

receives a signal from the ECM to prime the fuel system for

approximately 2 seconds before start. Priming the fuel system

provides for a quicker start when engine begins to crank.

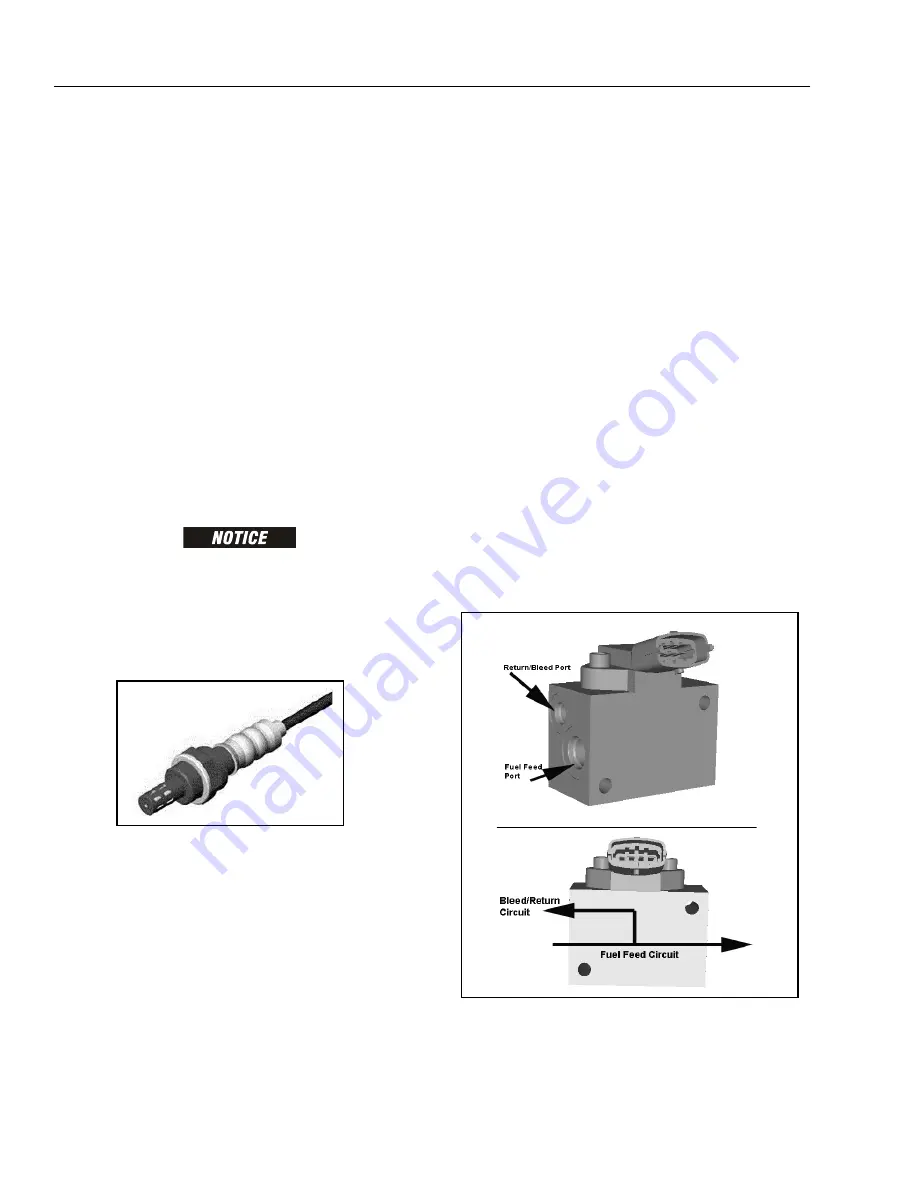

Gasoline Pressure And Temperature Sensor

Manifold

This engine is equipped with a fuel injector rail that does not

have a pressure regulator or a return circuit to the fuel tank.

Fuel pressure for this engine is regulated by the engine’s ECM.

The ECM receive fuel pressure and temperature feedback from

the gasoline fuel sensor manifold and uses this information to

control the ground side of the fuel pump. Fuel pressure is reg-

ulated by the ECM pulse width modulating (PWM) the fuel

pump. The fuel pressure and temperature sensor manifold has

a return or "bleed" circuit that connects back to the fuel tank.

This circuit is used to bleed off any vapor that develops in the

line and return a small amount of fuel to the tank.

Fuel comes from the fuel tank and passes through the fuel

pump. Fuel exits the fuel pump, passes through the filter and

then enters the fuel pressure and temperature manifold

assembly. Fuel flows through the feed circuit and is delivered

to the fuel injector rail. Fuel that enters the bleed circuits

through the bypass valve in the manifold is returned to the

fuel tank.

Figure 3-66. Heated Exhaust Gas Oxygen Sensor (HEGO)

Figure 3-67. Gasoline Fuel Pressure and Temperature

Manifold Assembly

Summary of Contents for 450A II Series

Page 46: ...SECTION 3 CHASSIS TURNTABLE 3 6 JLG Lift 3121290 Figure 3 4 Drive Hub 4WD Front Only ...

Page 79: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 39 Figure 3 32 Swing Bearing Drive ...

Page 101: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 61 Figure 3 42 Auxiliary Pump ...

Page 113: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 73 Figure 3 53 EMR2 Fault Codes Sheet 1 of 5 ...

Page 114: ...SECTION 3 CHASSIS TURNTABLE 3 74 JLG Lift 3121290 Figure 3 54 EMR2 Fault Codes Sheet 2 of 5 ...

Page 115: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 75 Figure 3 55 EMR2 Fault Codes Sheet 3 of 5 ...

Page 116: ...SECTION 3 CHASSIS TURNTABLE 3 76 JLG Lift 3121290 Figure 3 56 EMR2 Fault Codes Sheet 4 of 5 ...

Page 117: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 77 Figure 3 57 EMR2 Fault Codes Sheet 5 of 5 ...

Page 159: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 119 ...

Page 161: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 121 ...

Page 163: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 123 ...

Page 165: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 125 ...

Page 173: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 133 Sensor Transducer Type ...

Page 177: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 137 Sensor Transducer Type ...

Page 179: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 139 ...

Page 181: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 141 ...

Page 183: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 143 ...

Page 185: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 145 ...

Page 187: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 147 ...

Page 203: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 163 ...

Page 207: ...SECTION 3 CHASSIS TURNTABLE 3121290 JLG Lift 3 167 ...

Page 217: ...SECTION 4 BOOM PLATFORM 3121290 JLG Lift 4 5 Figure 4 2 Boom Limit Switches ...

Page 310: ...SECTION 5 HYDRAULICS 5 70 JLG Lift 3121290 NOTES ...

Page 312: ...SECTION 6 JLG CONTROL SYSTEM 6 2 JLG Lift 3121290 Figure 6 2 Controller Block Diagram 0 ...

Page 370: ...SECTION 6 JLG CONTROL SYSTEM 6 60 JLG Lift 3121290 NOTES ...

Page 394: ...SECTION 7 BASIC ELECTRICAL INFORMATION SCHEMATICS 7 24 JLG Lift 3121290 NOTES ...

Page 395: ......